Model coil spring device and control method for same

A technology of coil springs, control methods, applied in the direction of springs, measuring devices, springs/shock absorbers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

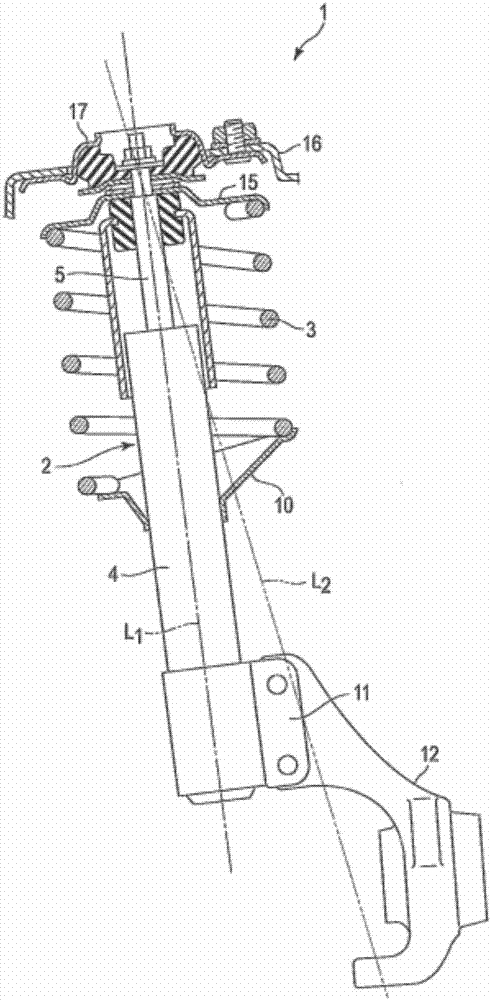

[0026] figure 1 A suspension device for a vehicle is shown, which is a MacPherson strut type suspension device 1 . The suspension device 1 includes a shock absorber serving as a strut 2, and a coil spring 3 for suspension (hereinafter simply referred to as a coil spring 3). The strut 2 includes an outer cylinder 4 as a first strut element 1 and a rod 5 as a second strut element. A rod 5 is inserted into the outer cylinder 4 . The rod 5 inserted into the outer cylinder 4 has a shock-absorbing structure. The outer cylinder 4 and the rod 5 are mutually along the L 1 The direction of the axis (strut axis) moves.

[0027] The outer cylinder 4 is disposed on the lower spring base 10 . The lower end of the outer cylinder 4 is placed on the bracket 11 . A joint material 12 is attached to the bracket 11 . The vehicle axle is supported by the joint material 12 . The upper end of the rod 5 is provided with an upper spring base 15 . A fixed insulator 17 is disposed between the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com