An automatic feeding system for intelligent cooking equipment

A technology for intelligent cooking and automatic feeding, applied in the field of automation, can solve the problems of inability to meet the individual taste, inaccurate delivery of seasonings, difficult to clean and replace, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

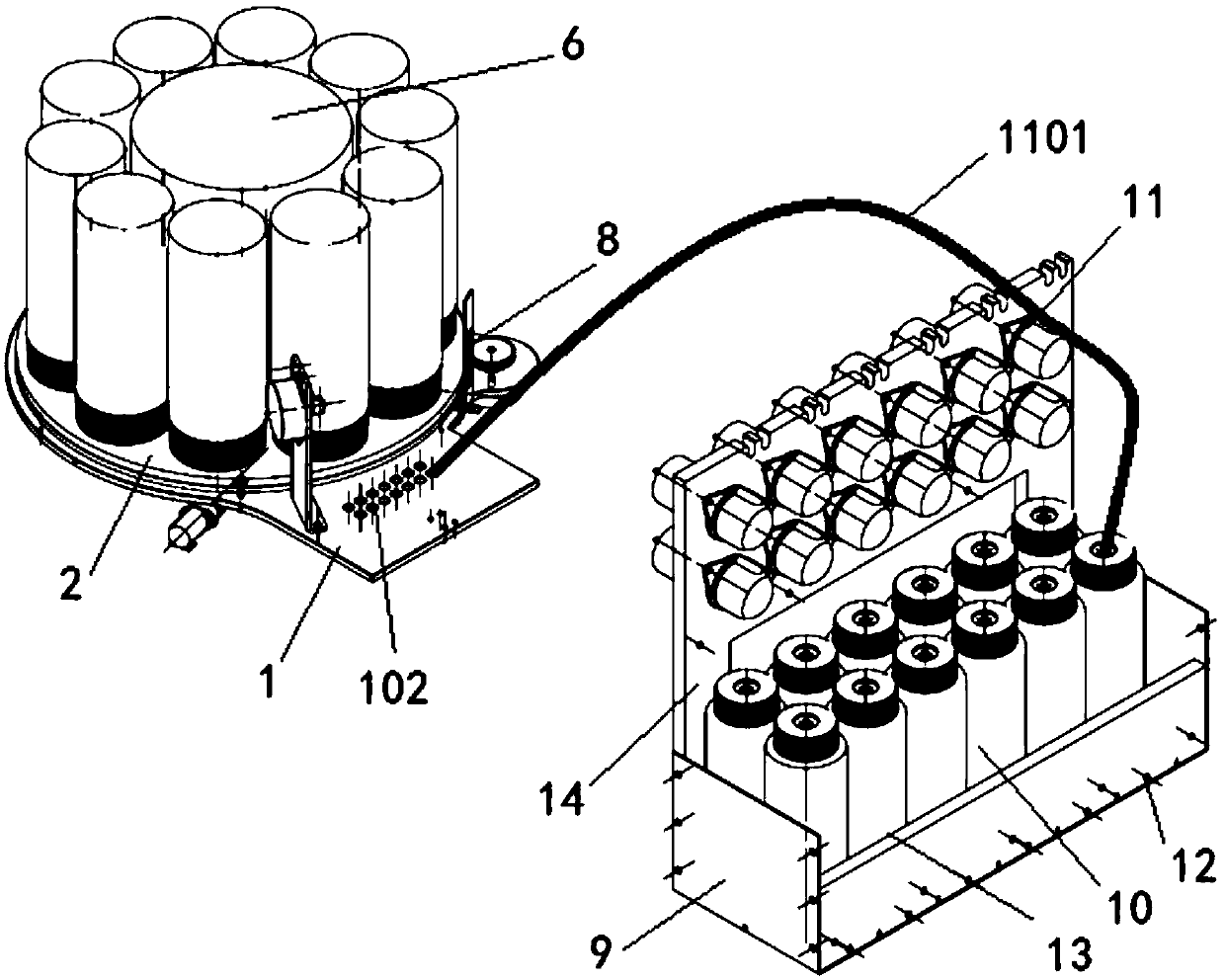

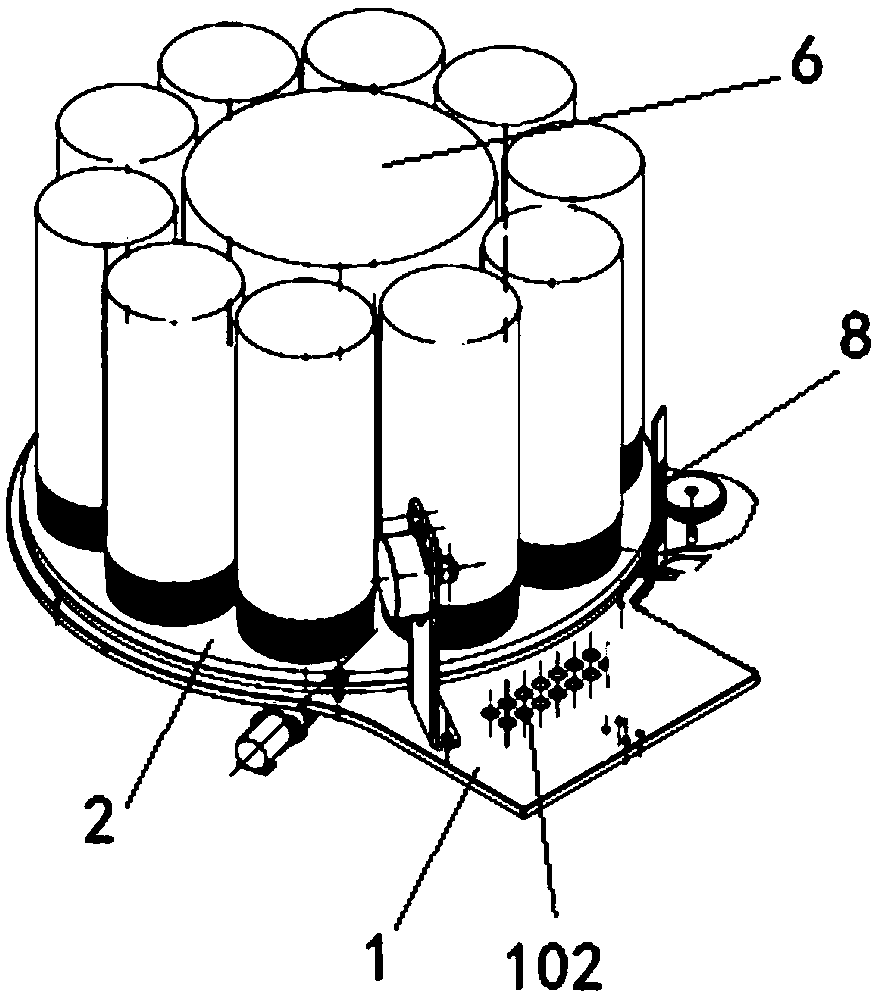

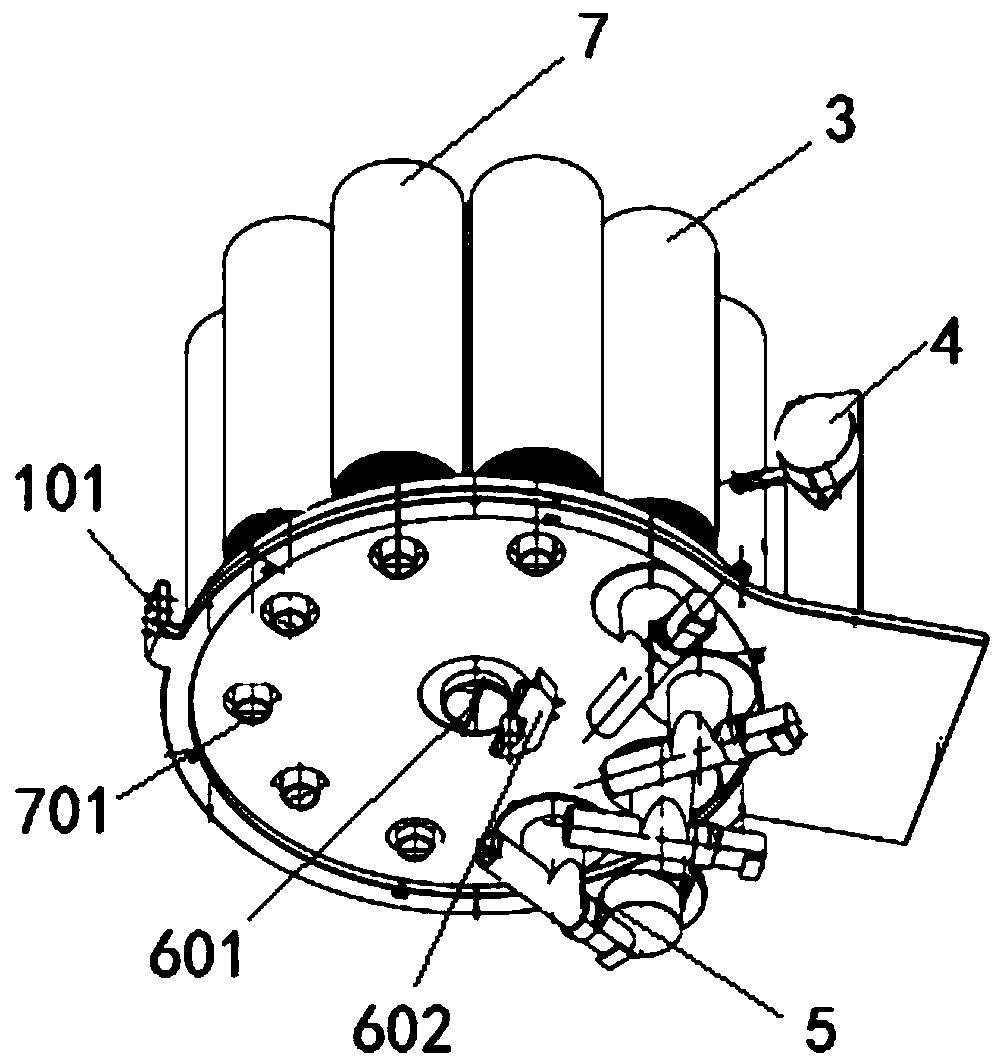

[0034] See attached Figures 1 to 7 According to a preferred embodiment of the present invention, an automatic feeding mechanism of intelligent cooking equipment controlled by an external electric control system, since there are not only liquids and solids but also large solids and thick seasonings during the cooking process, Therefore, the automatic unloading system of the present application includes a non-liquid unloading mechanism and a liquid unloading mechanism, wherein the non-liquid unloading mechanism includes a base 1, and the base 1 is provided with a turntable 2 connected to it in rotation. Driven by the fourth motor, in order to place solids and large-grain s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com