Spraying water recycling device for water-curtain spray booth

A technology for spraying water and spray booths, which is applied to the device and coating of the surface coating liquid, which can solve the problems of unfavorable recycling and reuse of spray water, consume manpower and material resources, increase production costs, etc., and achieve the improvement of photoelectric devices. Change efficiency, optimize energy use, and save waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

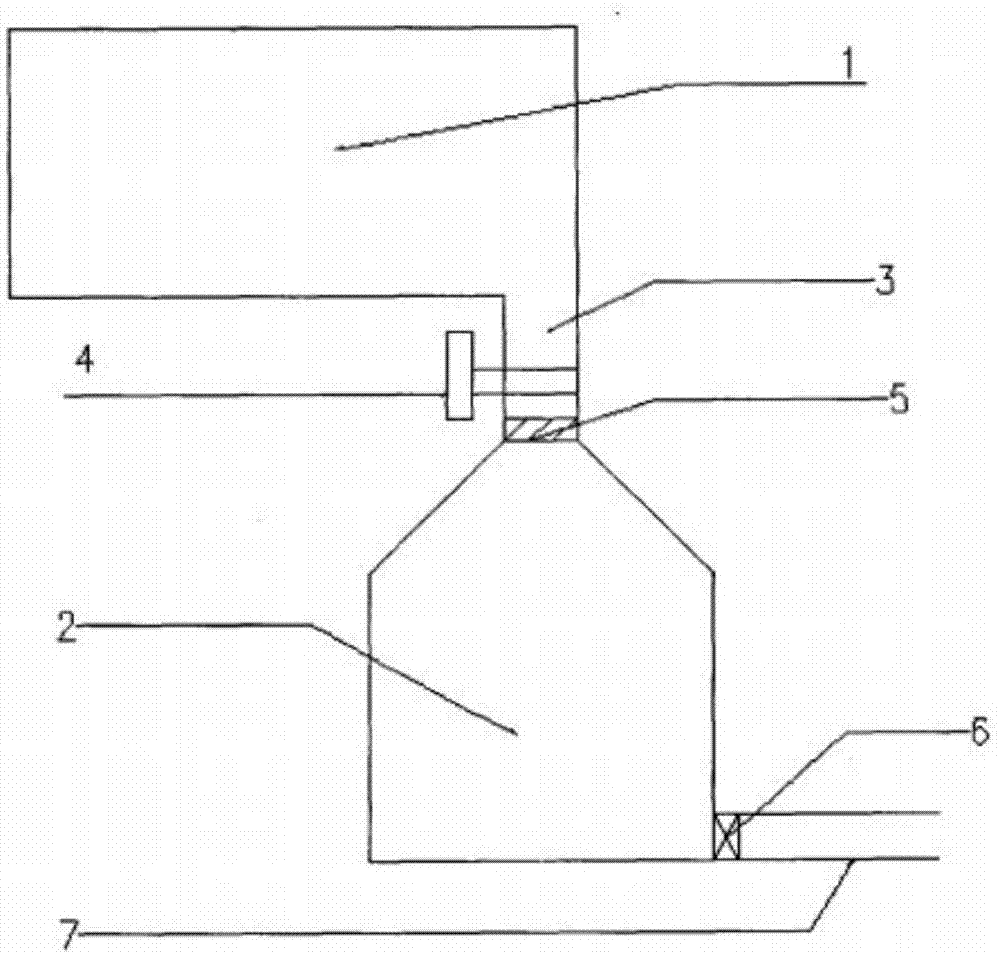

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0013] figure 1 The reference signs shown are as follows: a water collection tank 1, a filter recovery tank 2, a spray water inflow pipe 3, a control valve 4, a detachable coarse mesh 5, a detachable fine mesh 6, and a recovery water output pipe 7.

[0014] exist figure 1 In the schematic diagram of a reuse device for spraying water in a water curtain spray booth, its main structure includes: filter recovery tank 2, control valve 4, detachable coarse net 5, detachable fine net 6, recycled water Output pipe 7.

[0015] The filter recovery tank 2 is connected to the sump 1 through the spray water inflow pipe 3, and a control valve 4 and a detachable coarse mesh 5 are added at the connection between the spray water inflow pipe 3 and the recovery tank 2, and the control valve 4 When the detachable co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com