Tiltable roller machine and automobile cavity wax injection technology achieving implementation through tiltable roller machine

A rolling bed and bed body technology, which is applied in the field of wax injection in automobile cavities, can solve problems such as difficulty in filling wax liquid, and achieve high wax injection and cooling efficiency, stable process, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

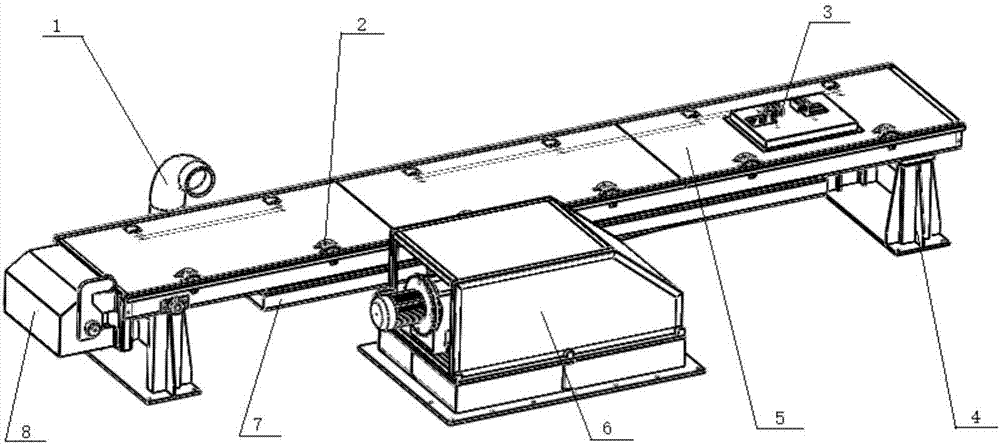

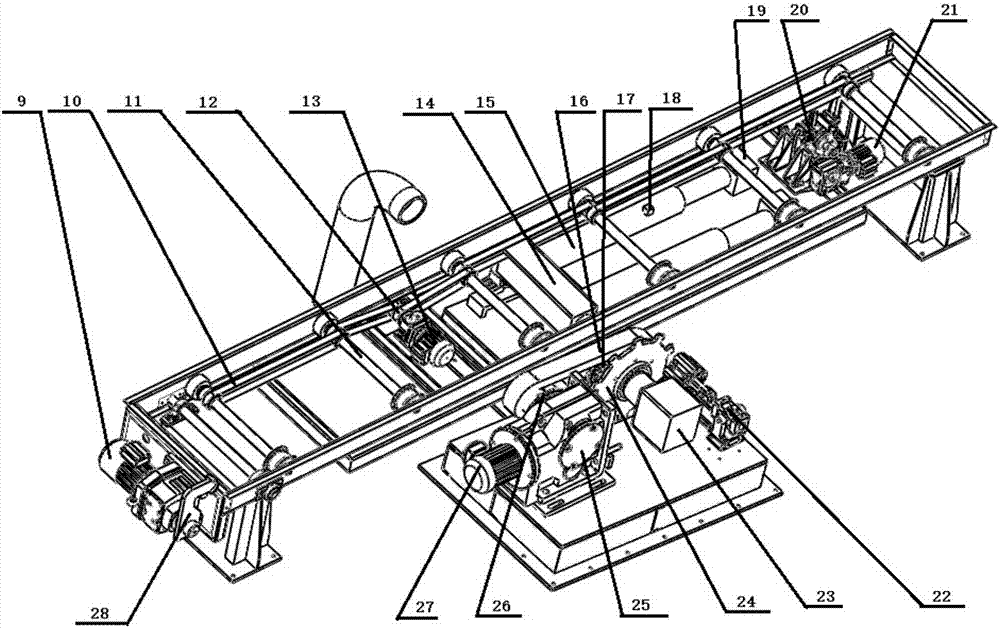

[0041] Such as figure 1 and 2 The tilting trundle shown includes:

[0042] The bed body comprises a bed body drive motor 13, a drive pulley 12, a belt 10, a roller shaft 11 and a roller 2. After the bed drive motor 13 is started, the drive pulley 12 is driven to rotate, thereby driving the belt 10 to move. The lower roller shaft 11 rotates, and the rollers 2 are installed at both ends of the roller shaft 11, and rotate with it;

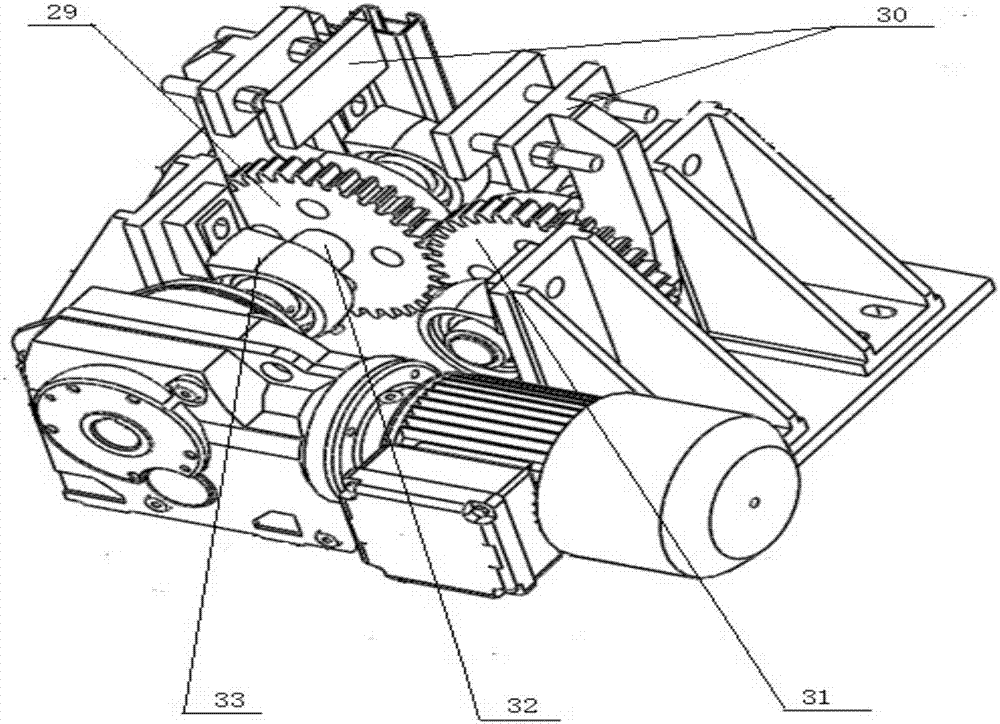

[0043] Tilt power unit 6 comprises tilt drive motor 27, tilt drive motor reducer 25, first pulley 26, synchronous belt 16, second pulley 17, connector 14, telescopic rod 15 and solenoid coil 19, tilt drive motor After 27 starts, drive the tilting drive motor reducer 25, the output shaft of the tilting drive motor reducer 25 is connected with the first pulley 26, the first pulley 26 rotates to drive the synchronous belt 16 to rotate, and then drives the second pulley 17 to rotate, The connecting piece 14 is rigidly connected with the output shaft of t...

Embodiment 2

[0052] Utilize the process in the wax injection of automobile cavity shown in embodiment 1 that can be inclined rolling bed to implement, comprise the following steps:

[0053] Step 1: Fix the treated car shell on the carrying tray, and the carrying tray is transported to the bed body of the tiltable roller bed through the roller conveyor, and the electric control device controls the tray to stop;

[0054] Step 2: Start the motor of the front-end clamping device, drive the front-end clamping arm to lift up, clamp the front end of the carrying tray, start the motor of the rear-end clamping device, drive the rear-end clamping arm to lift, and lift the rear beam of the carrying tray Clamp;

[0055] Step 3: Start the tilting drive motor, the tilting power unit is partially operated, and the telescopic rod is driven to lift up. At the same time, the solenoid coil is energized to make it magnetically adsorbed to the bed body, so that the bed body is lifted around the shaft axis, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com