Tool for quickly removing paint on circumference of hole

A fast and paint technology, applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as increased protection costs, and achieve the effect of ensuring correctness, simple and fast operation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be described below in conjunction with specific embodiments.

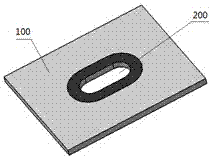

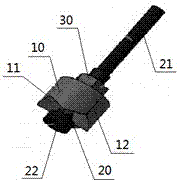

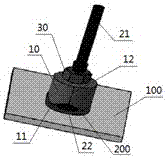

[0013] by figure 1 as a benchmark, such as figure 2 with image 3 As shown, it is a structural schematic diagram of a tool for quickly removing paint around holes according to the present invention.

[0014] The tool for quickly removing the paint around the hole circle according to the present invention includes: a cutter body 10, a handle 20 and a fastening nut 30, the external thread of the handle 20 is screwed into the internal thread of the cutter body 10, and at the same time tightening The solid nut 30 is tightened and connected as a whole. One end of the handle 20 is provided with a handle clamping end 21, and the other end of the handle 20 is provided with a circular boss 22; the handle 20 is used to drive the body 10 to quickly rotation, in addition, the circular boss 22 acts as a limiter when it is connected to the knife handle 20; Moving in the oblon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com