Continuous mold cutting and folding mechanism

A continuous cutting and cutting technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increasing the process of manually selecting waste and products, increasing production costs, and low production efficiency, so as to save the selection of products and The effect of waste processing, production efficiency improvement, and competitiveness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

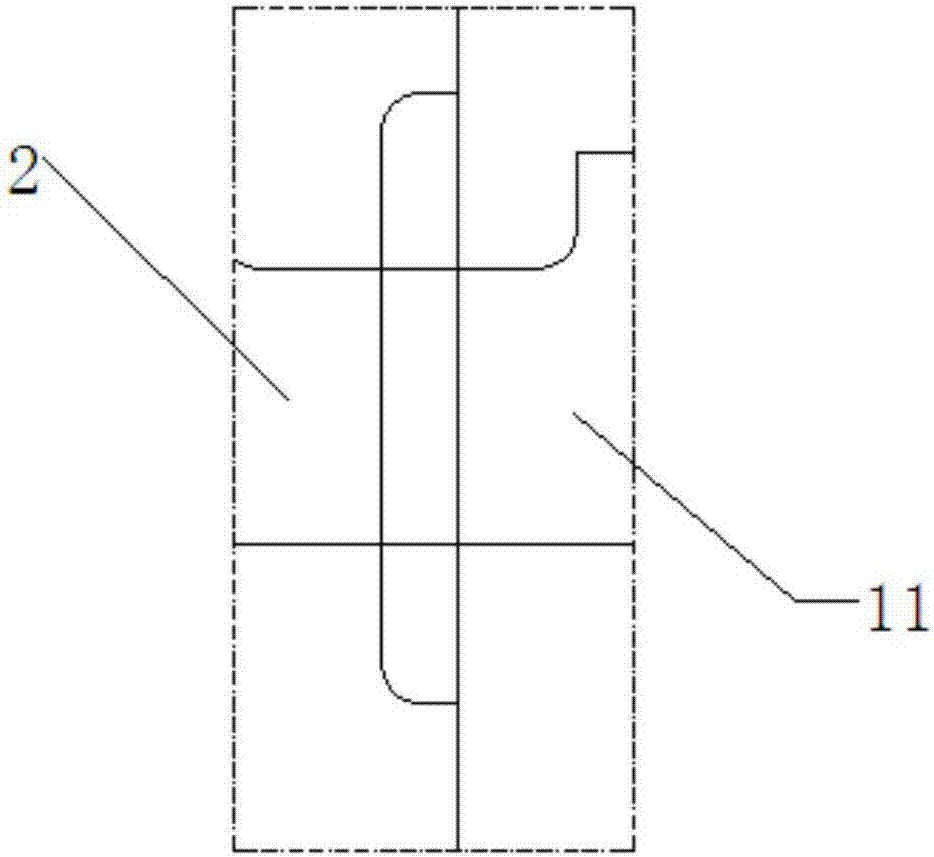

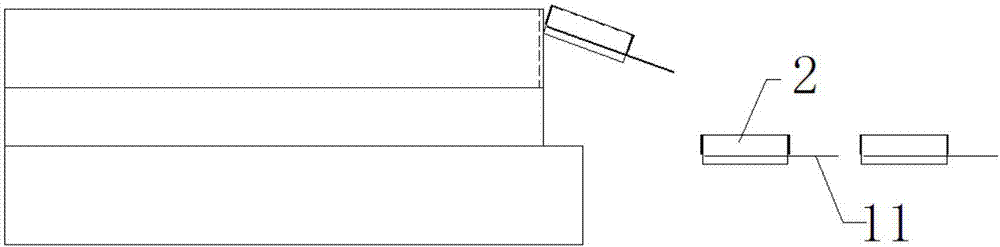

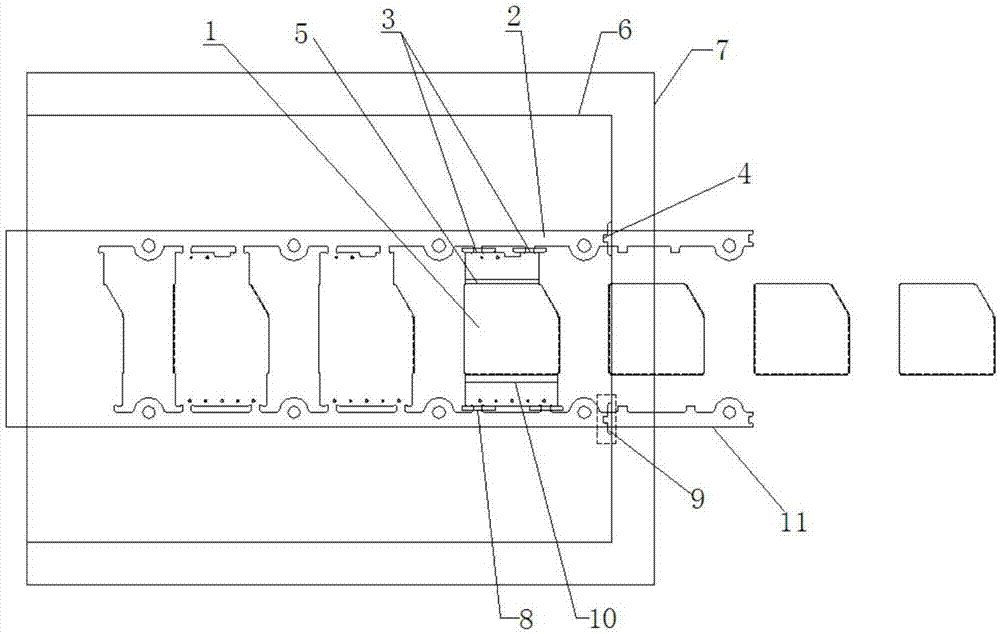

[0020] Such as image 3 , Figure 4 with Figure 5 As shown, a continuous die continuous cutting belt folding structure is used for the last step of the continuous die to cut off the first connection point 3 between the product 1 and the two material belts 2 on the left and right sides, and to cut off the waste corresponding to the previous product and the current product The second connecting point 4 between the corresponding strips and the preset bending place 5 on the bent product are characterized in that they include an upper mold base 6 and a lower mold base 7, and the upper mold base and the lower mold base A cutting knife set 8 for cutting off the first connection point, a waste knife set 9 for cutting off the second connection point, and a bending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com