Prefabricated hollow interlayer concrete-filled steel tube member and preparation method thereof

A concrete-filled steel tube and prefabricated technology, which is used in bridge parts, reinforcement molding, construction, etc., can solve the problem that the confinement effect of core concrete cannot be fully exerted, affecting the durability and mechanical properties of components, hoop capacity and inner rigid tube bearing capacity It can reduce the anti-corrosion treatment process, avoid the local buckling problem, and improve the seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

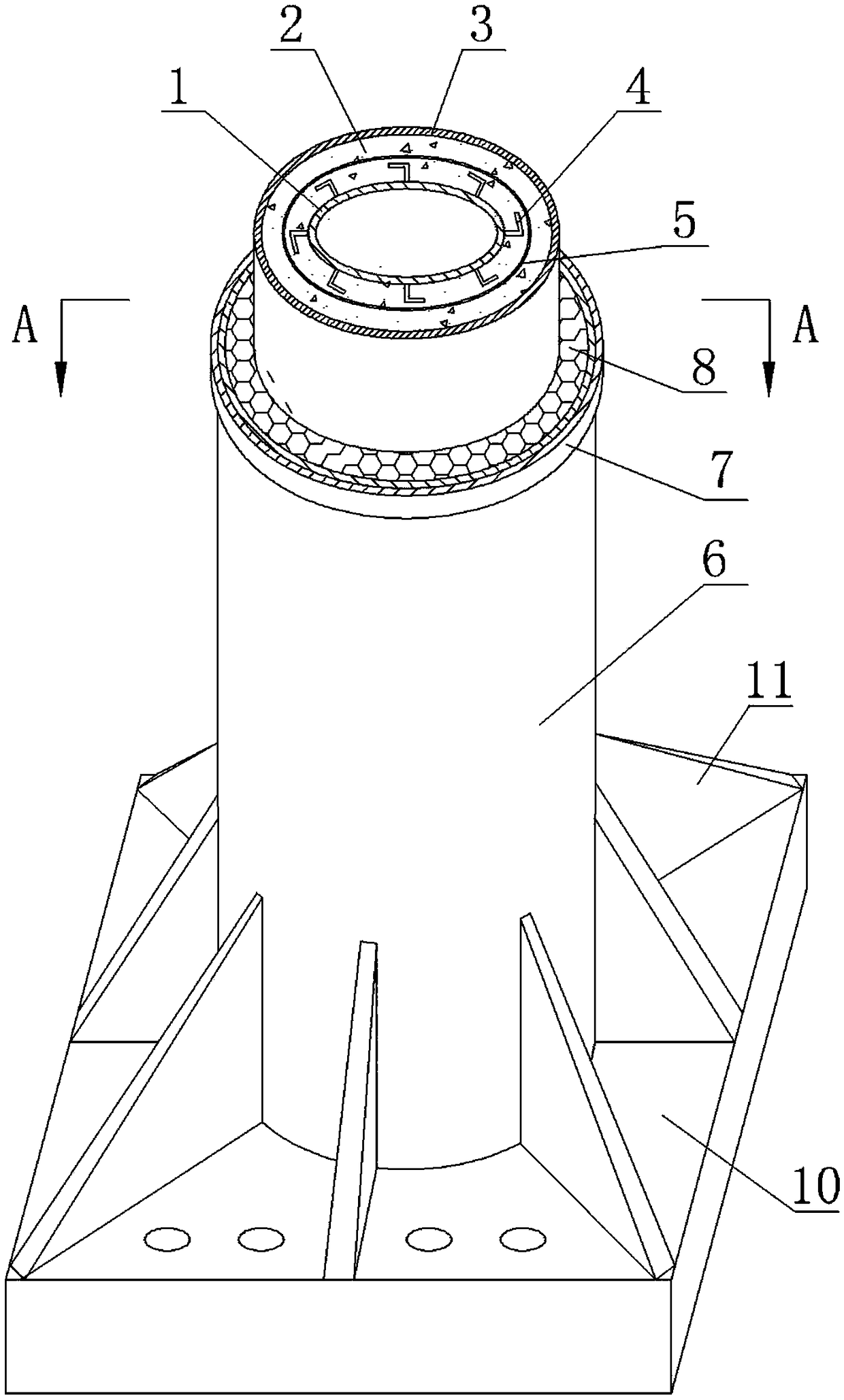

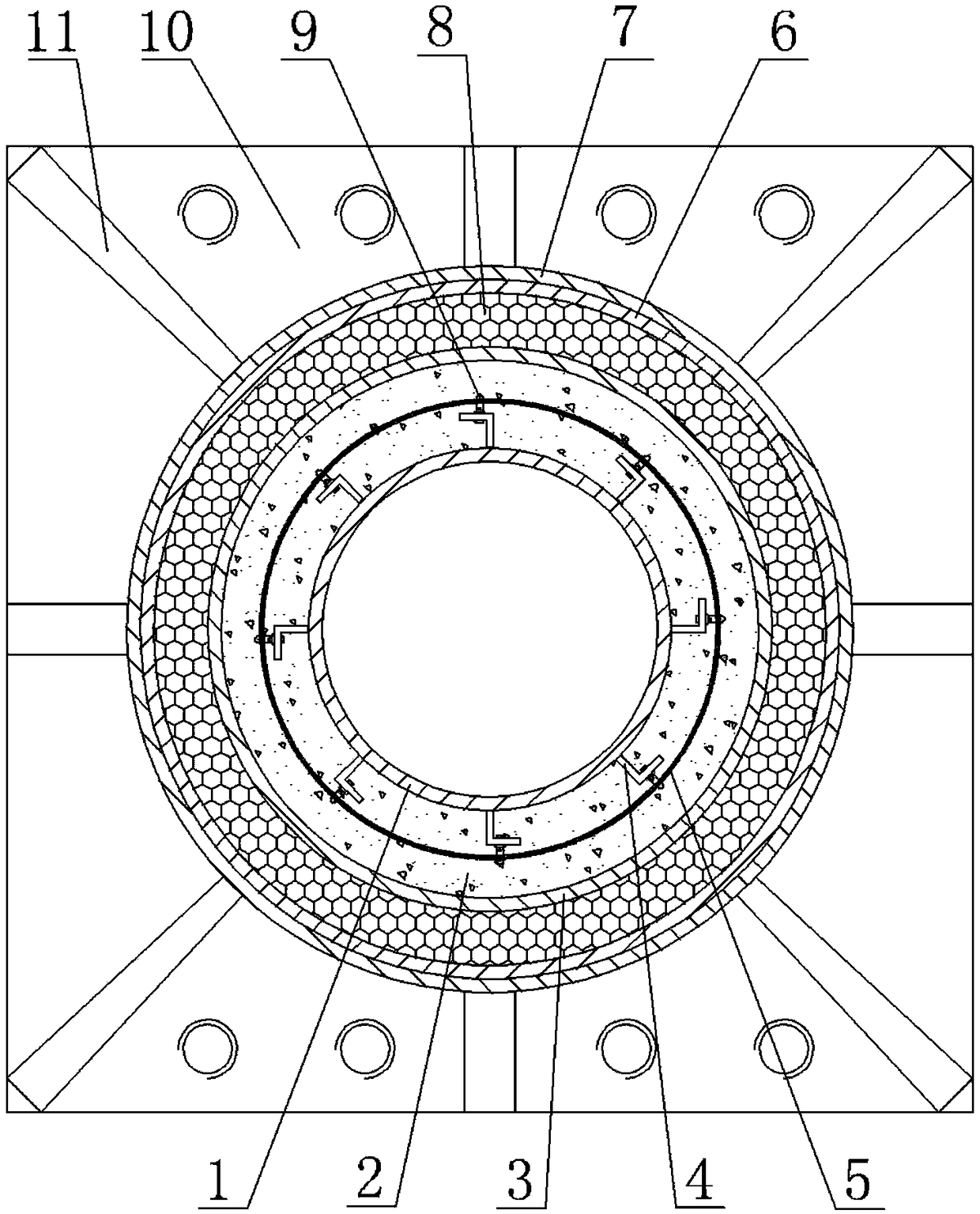

[0036] from Figure 1 to Figure 3 It can be seen that the assembled hollow sandwich concrete-filled steel tubular member of the present invention includes a circular inner steel pipe 1, a concrete 2, a circular outer steel pipe 3, an angle steel stiffener 4, a steel mesh 5, a circular casing 6 and prestressed collar 7,

[0037] The outer steel pipe 3 is set outside the inner steel pipe 1 and arranged concentrically with the inner steel pipe 1.

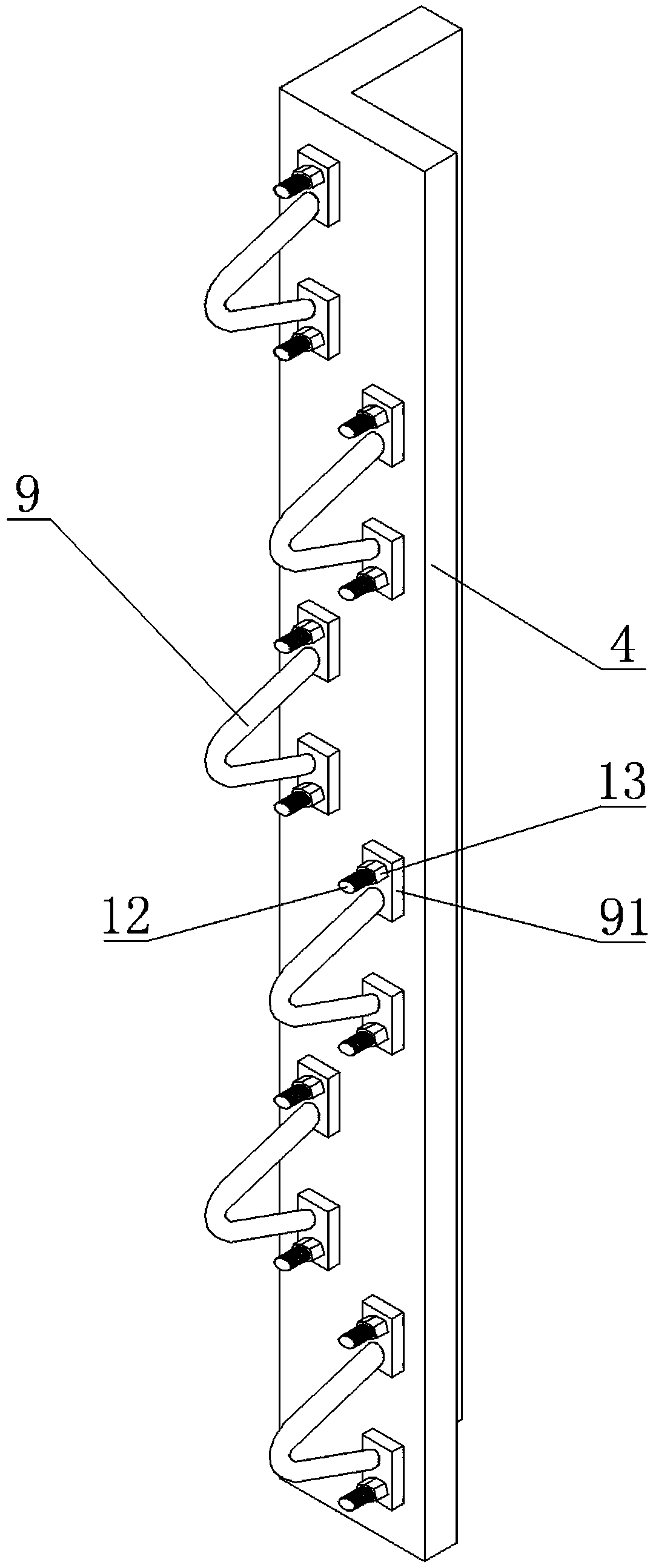

[0038] Each angle steel stiffener 4 is vertically welded on the outer wall of the inner steel pipe 1 along the axis of the inner steel pipe 1, and each angle steel stiffener 4 is evenly arranged around the axis of the inner steel pipe 1, and is fastened on the outer wall of each angle steel stiffener 4 by threads. There are several V-rings 9 fixedly fixed at staggered intervals.

[0039] The steel mesh 5 is hung on the V-shaped ring 9, and the steel mesh 5 is hooped on the outside of the angle steel stiffener 4 through each V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com