Full-automatic cloth machine

A kind of cloth machine, fully automatic technology, applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, etc., can solve the problems that cannot meet the needs of enterprise automation development, low processing efficiency, and restrict the development of enterprises, so as to meet the needs of production development, Easy to operate, labor-saving, and high promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

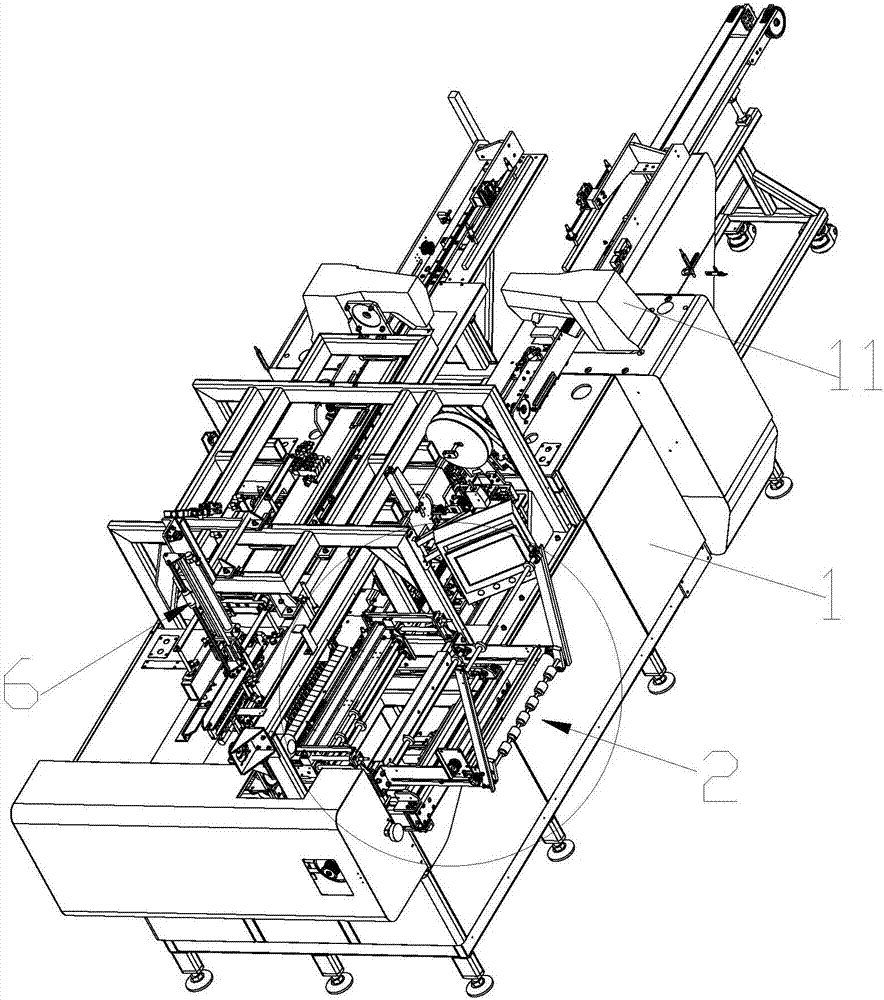

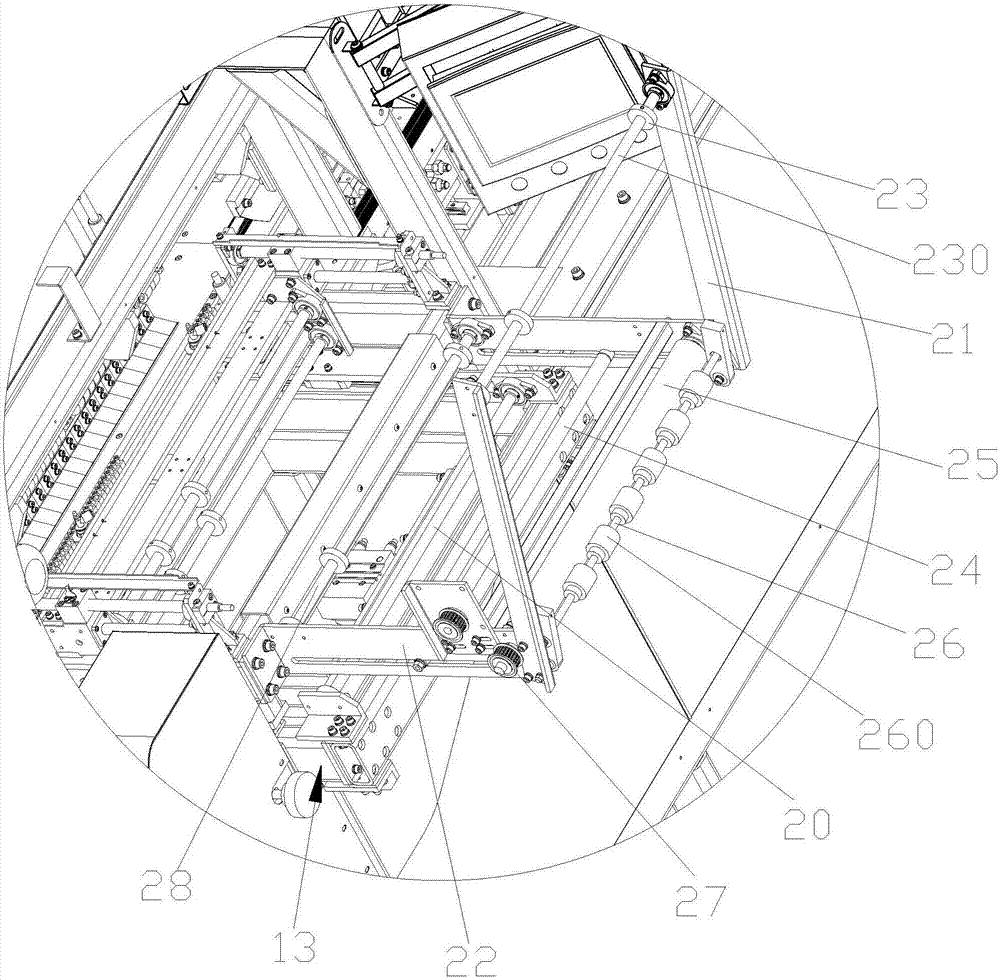

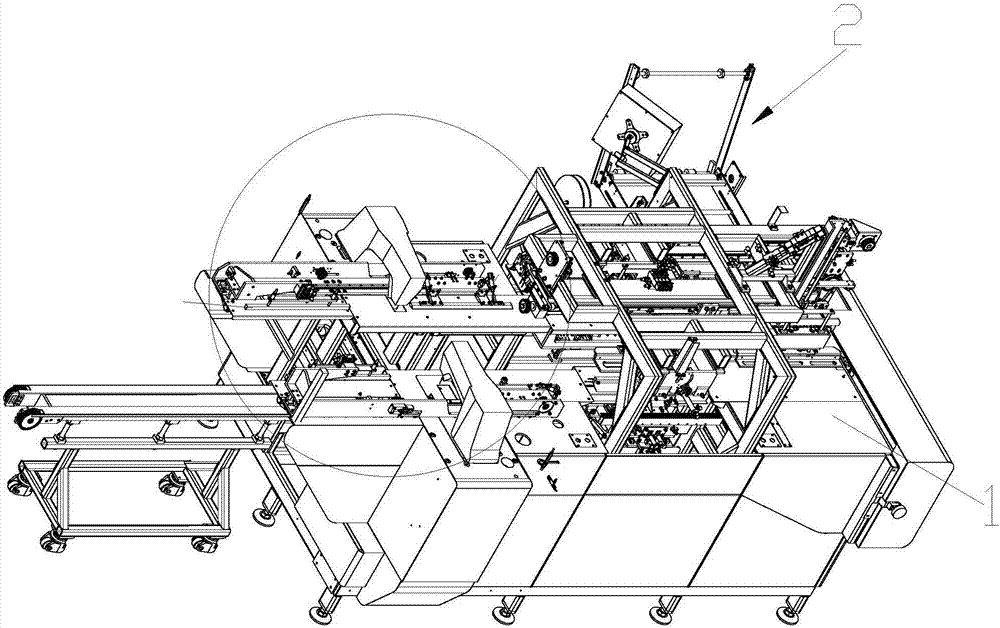

[0040] as attached Figure 1-9 The shown a kind of fully automatic distributing machine of the present invention comprises a frame 1, a feeding mechanism 1 located on the frame 1, an ironing mechanism 13, a roughing mechanism 3, a cloth grasping mechanism 5, and a cloth cutting mechanism 4 , synchronous cloth moving mechanism 7, fixed-length mechanism 6, hemming structure, trademark mechanism (not shown in the figure), superscript mechanism 9, sewing mechanism 10, sewing machine 11 and blanking structure 12; the feeding mechanism 2 , the ironing mechanism 13 and the cloth grabbing mechanism 5 are distributed on the frame 1 in turn; the roughening mechanism 3 is arranged between the ironing mechanism 13 and the cloth grabbing mechanism 5; Mechanism 4; a synchronous cloth moving mechanism 7 that can move up and down is provided between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com