A high-pressure water-air jet fine water mist dust reduction and gas control device at the fully-mechanized mining coal outlet

A technology of fine water mist and coal discharge port, which is applied in the direction of safety devices, dust prevention, mining equipment, etc., and can solve problems such as reluctance to operate the spray switch, weak dust prevention awareness of workers, and small flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

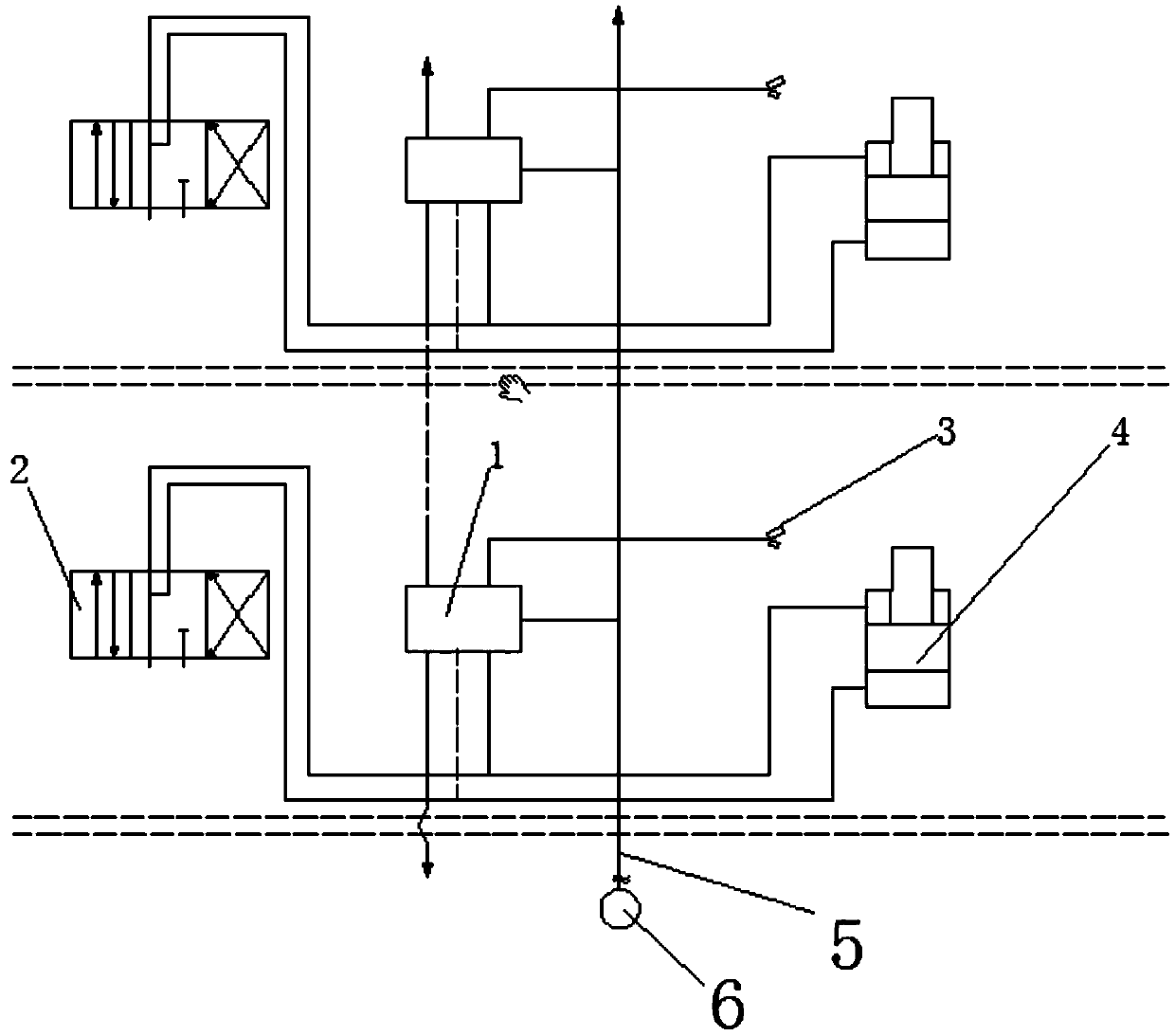

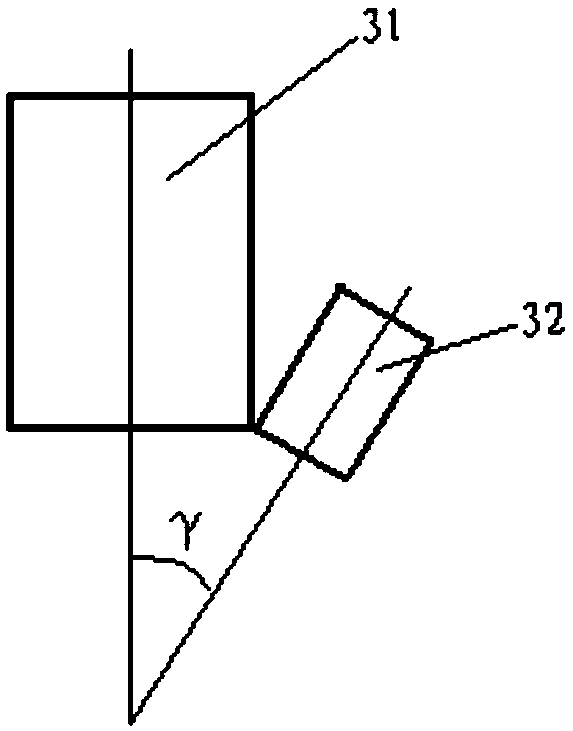

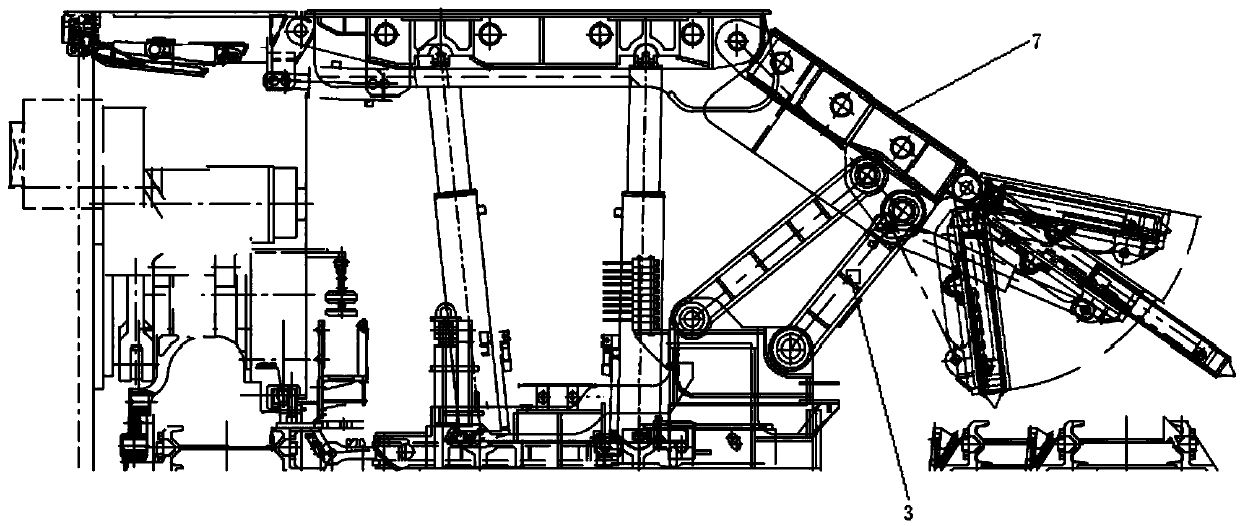

[0027] Such as figure 1 with image 3 As shown, the high-pressure water-gas jet fine water mist dust control gas control device for fully mechanized coal caving mouth of the present invention has many side-by-side hydraulic supports, and a coal caving control piece is installed on each hydraulic support The valve 2 and the coal caving control cylinder 4, the coal caving control valve 2 and the coal caving control cylinder 4 are connected by an emulsion pipeline, and each hydraulic support is also provided with a coal caving linkage valve 1 and the rear connecting rod of the hydraulic support A self-priming water-air jet and water mist assembly 3 is provided on the upper part. The self-priming water-air jet and water mist assembly 3 is installed on the rear connecting rod 7, and its outlet p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap