Pintle Type Varying Throat Diameter Nozzle Device for Solid-liquid Hybrid Rocket Engine

A rocket engine and solid-liquid mixing technology, which is applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems that cannot be applied to theoretical research, cannot be integrated into nozzles, and cannot realize pressure regulation and control of combustion chambers, etc. problems to achieve research-friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

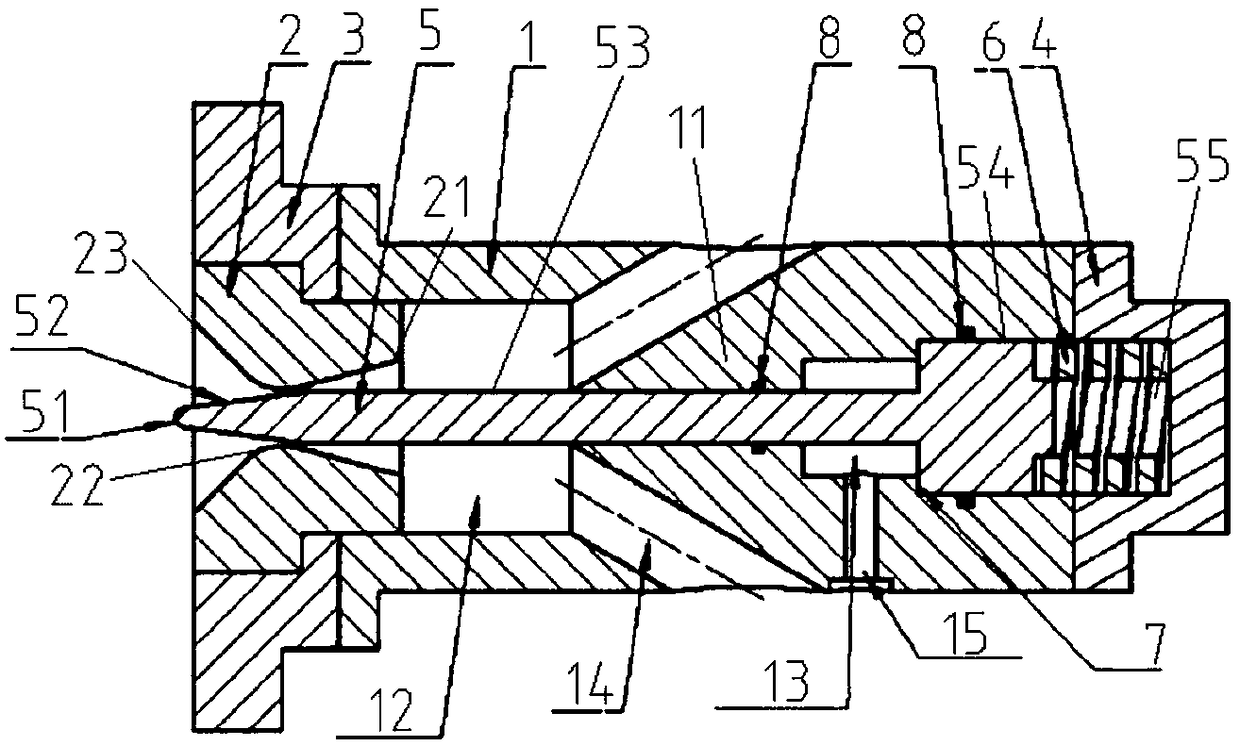

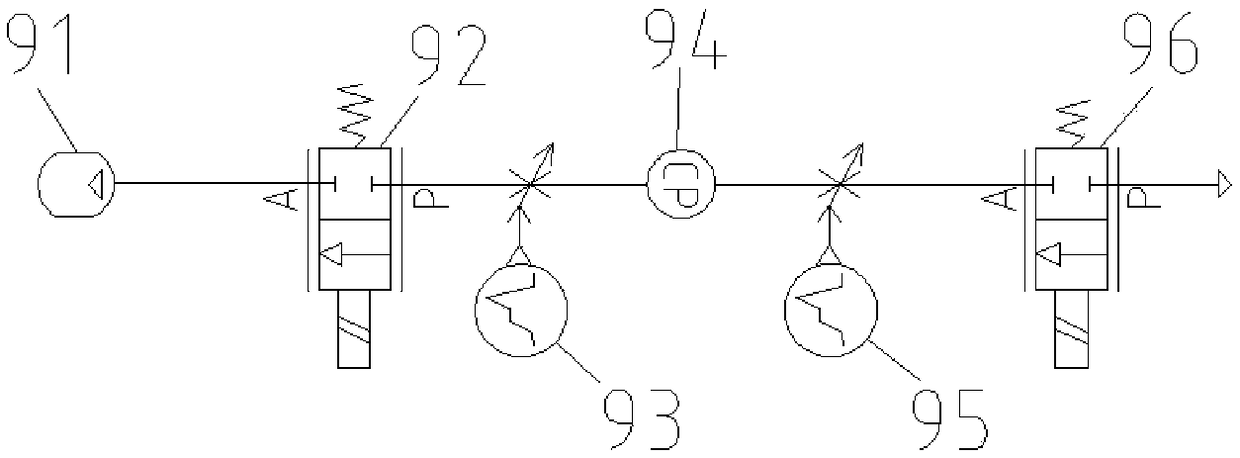

[0036] figure 1 It is a schematic structural diagram of a needle-bolt type variable throat nozzle device of a solid-liquid hybrid rocket motor provided in the first embodiment of the present invention; figure 2 It is a schematic diagram of the structure of the high-pressure gas circuit provided in the first embodiment of the present invention; Figure 1-Figure 2 As shown, the needle plug type variable throat nozzle device of a solid-liquid hybrid rocket engine provided by the present invention includes a housing 1, a nozzle 2, a nozzle housing 3, an end cover 4, a needle 5 and a spring 6;

[0037] The housing 1 is divided into a gas cavity 12 and a high-pressure gas cavity 13 by a pin fitting section 11. The housing 1 is provided with a gas passage 14 communicating with the gas cavity 12 and the high-pressure gas cavity 13 Connected air inlet 15;

[0038] The nozzle 2 is connected to one end of the gas chamber 12 of the casing 1 through the nozzle housing 3, and the nozzle housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com