Process method for non-inverted formation of bottom lead-out device

A process method and device technology, which is applied in the field of safety and reliability of electronic components, can solve problems such as short lead wires and inability to meet inversion forming, achieve good universality, improve environmental adaptability, and meet welding strength requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

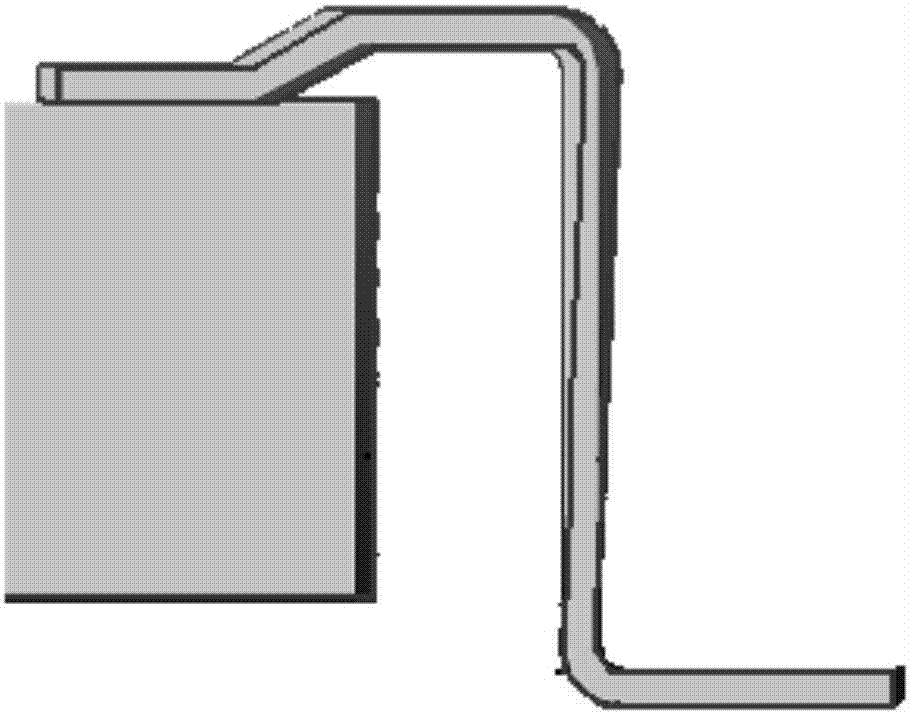

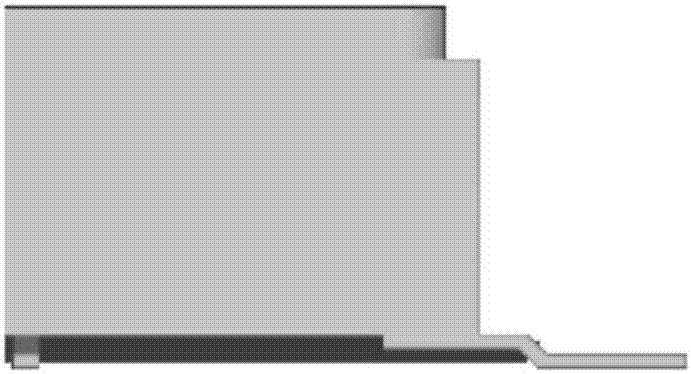

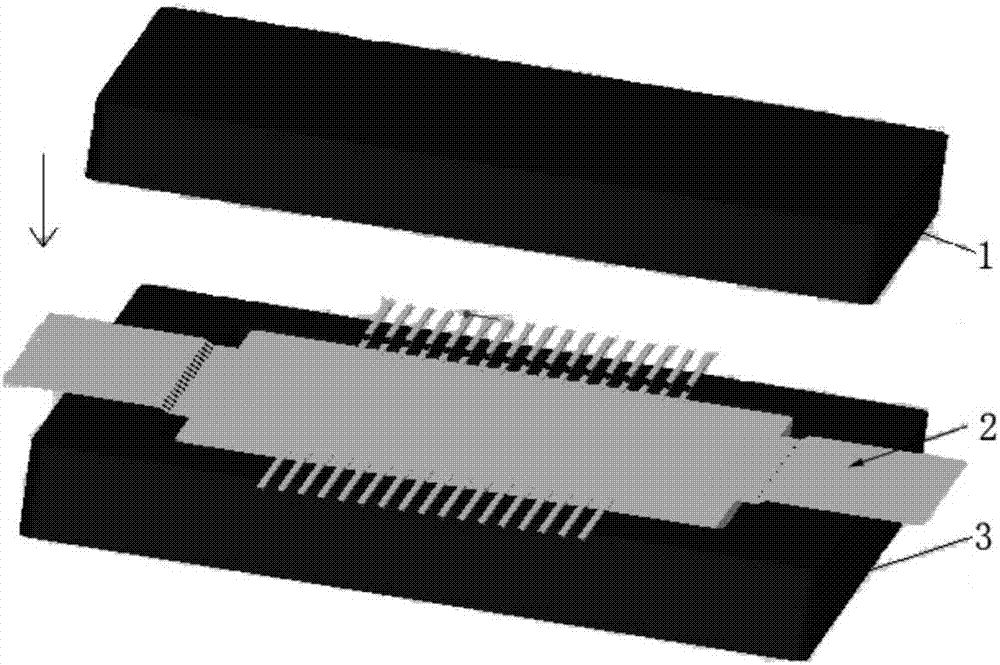

[0029] The invention discloses a process method for non-inverted forming of bottom-leading devices, which is different from the traditional inverting forming method, but adopts a non-inverting forming method that is compatible with the lead length of the original device, and is based on domestic bottom-leading QFP and SOP packaging devices. Particularity, that is: the way the device leads extend out is from the bottom, and the length of the device leads is relatively short. However, the above two characteristics cannot meet the requirements of QJ 3171 "Technical Requirements for Forming Components of Aerospace Electronic and Electrical Products", resulting in the failure of the device to be formed, and the solder joints may be affected by stress after welding in the later stage. Design a new forming method and a special forming tool for the implementation process, which can carry out non-inverted forming of domestic bottom-leading QFP and SOP packaged devices. After forming, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com