Multipurpose hard stem plant cuttage operation tail end executer

An end-effector and multi-purpose technology, applied in planting methods, botanical equipment and methods, applications, etc., can solve problems such as high production costs, low production efficiency, and difficulty in ensuring cutting quality, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

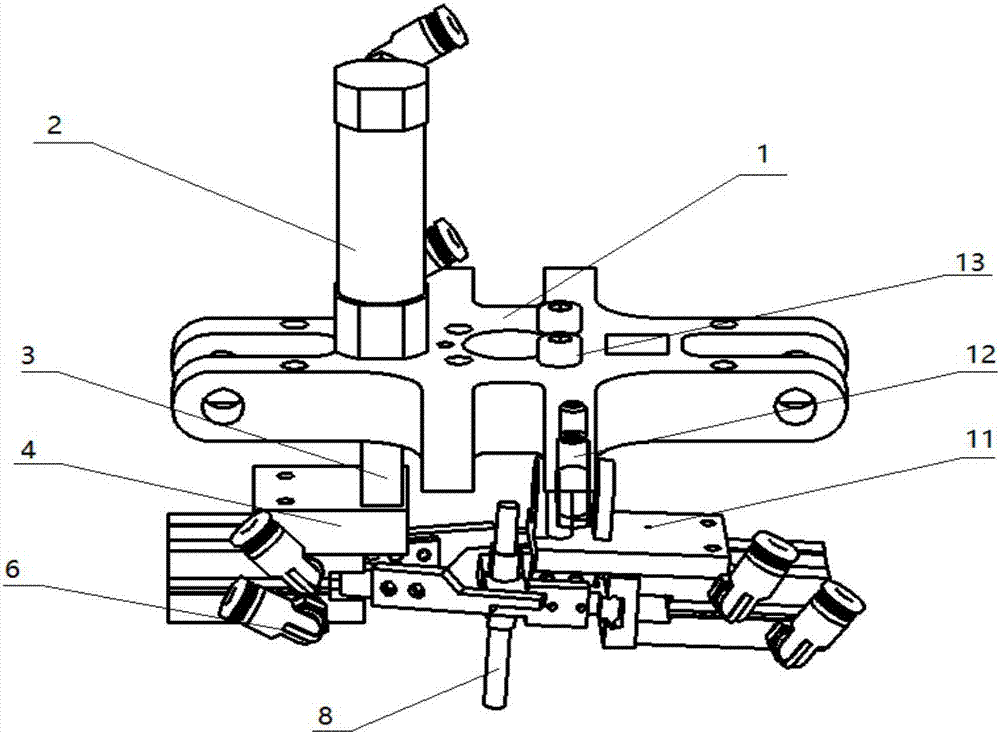

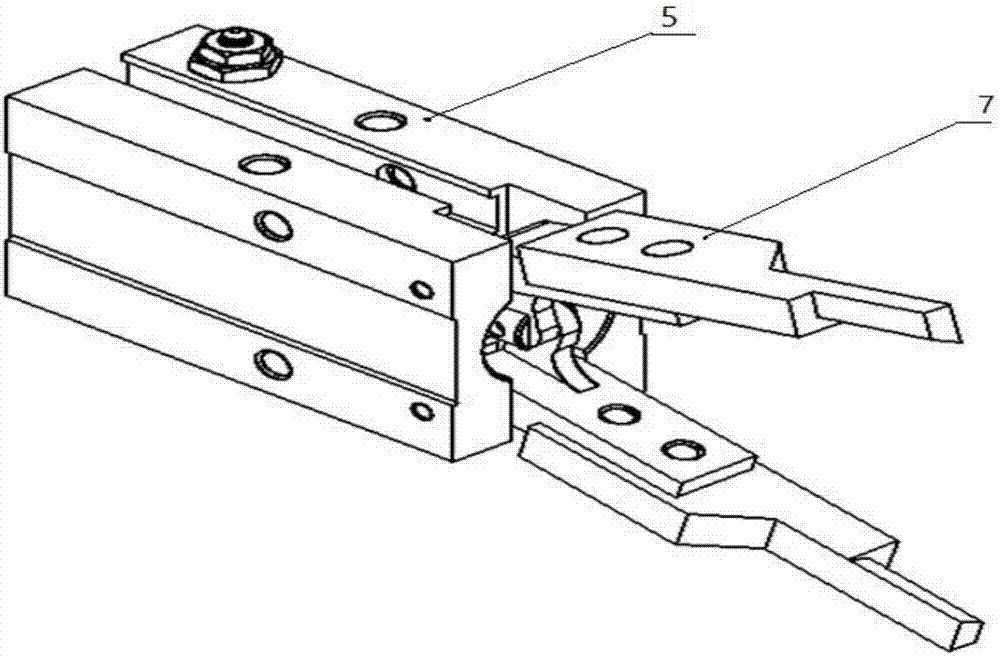

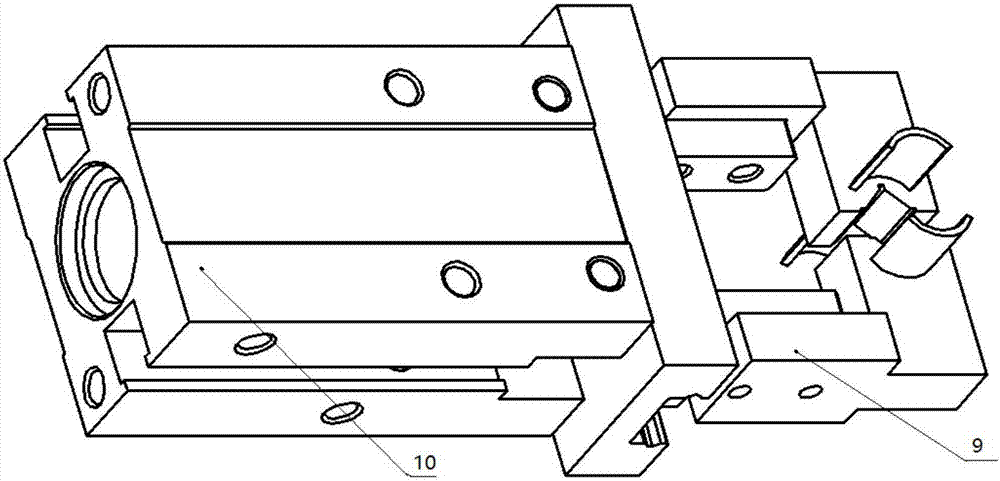

[0031] The multipurpose end effector for cuttage operation of hard stem plants according to the present invention mainly includes a cutting part, a clamping part and a cylinder. In the cutting operation, it is required to complete three actions: cutting, clamping, and inserting soil. Through the image recognition feedback technology, the position of the strip seedlings is first obtained through image recognition technology, and then according to the results of image recognition, the three actions of cutting, gripping and inserting soil are completed on the end effector. During a working cycle, the end effector not only completes the action of inserting soil, but also completes the clamping and cutting of the cutting parts of hard-stem plants, so as to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com