A system for combined cooling and heating using waste heat of marine diesel engines and a method for using the same

A marine diesel engine and combined cooling and heating technology, which is applied to machines that use waste heat, machine operation methods, mechanical equipment, etc., can solve the problems of single waste heat return water utilization, high cost, and limited application range, etc., to achieve The effect of saving water consumption of ships, saving device costs and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

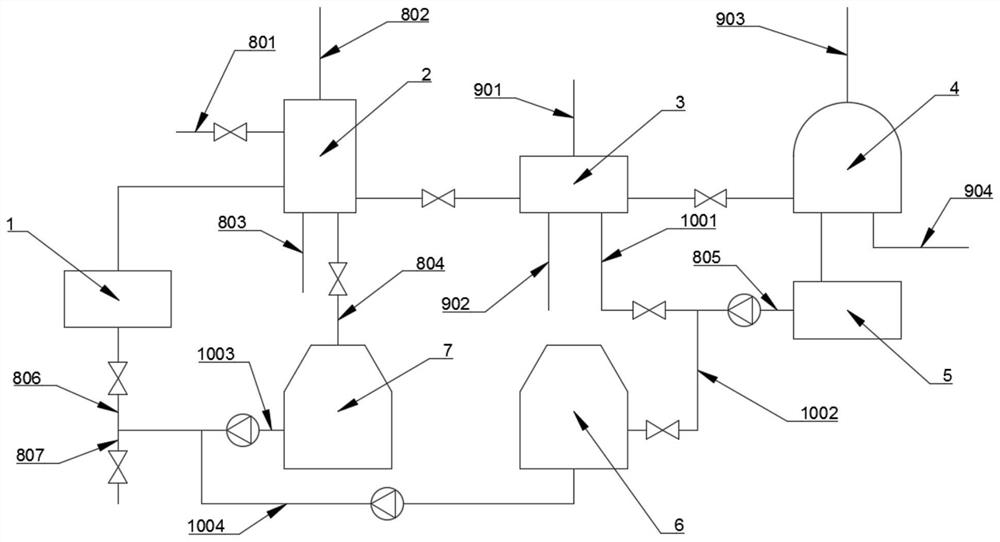

[0047] Such as figure 1 As shown, this embodiment provides a system for combined cooling and heating by using waste heat from marine diesel engines, including a radiator (1), a plate heat exchanger (2), a heat pipe type waste heat recovery heat exchange system connected in sequence with preset pipes device (3), lithium bromide refrigeration unit (4), condenser (5), also includes the first hot water storage tank (6), the second hot water storage tank (7);

[0048] Water pipe I (801), water pipe II (802) and water pipe III (803) are additionally provided on the plate heat exchanger (2), which are respectively used for tap water b 1 inflow, jacket water a 1 Inflow, jacket water a 2 outflow; the plate heat exchanger (2) is connected to the second hot water storage tank (7) through the water pipe IV (804);

[0049] The heat pipe type waste heat recovery heat exchanger (3) is provided with air pipe I (901) and air pipe II (902), which are respectively used for flue gas c 1 inflo...

Embodiment 2

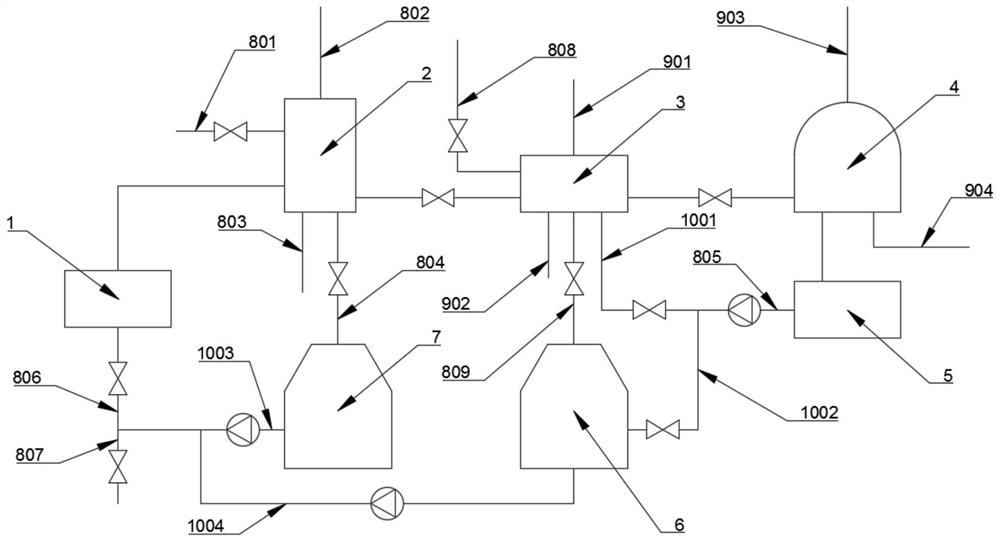

[0062] Such as figure 2 As shown, in order to provide better refrigeration and heating effects, the system for combined cooling and heating by using the waste heat of marine diesel engines provided in this embodiment has the following improvements on the basis of Embodiment 1: the heat pipes in the system A water pipe Ⅷ (808) is also provided on the waste heat recovery heat exchanger (3), and a water pipe Ⅸ (809) is connected between the heat pipe waste heat recovery heat exchanger (3) and the first hot water storage tank (6). Throttle valves are respectively set on the water pipes VIII (808) and IX (809).

[0063] Through the above improvements, the system of this embodiment can achieve targeted adjustments to hot or cold environments by closing certain throttle valves, and can provide a correspondingly more comfortable living environment in the cabin.

[0064] When the surrounding climate is hot, use the following methods to further improve the cooling effect of the cabin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com