Conveying vegetable pressing device

A conveying device and vegetable pressing technology, which is applied in conveyors, transportation and packaging, metal processing, etc., can solve the problems of no power for the rollers, failure to standardize dishes, and short pressing time, so as to achieve good pressing effect and improve regularity effect, the effect of no food sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

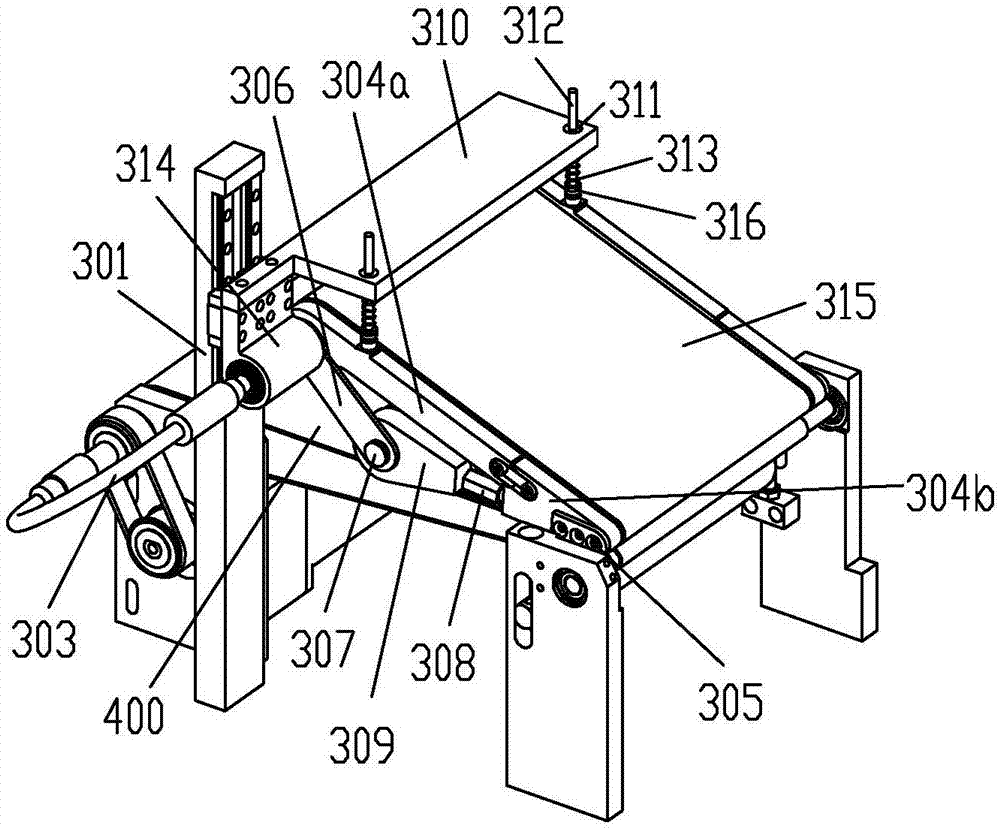

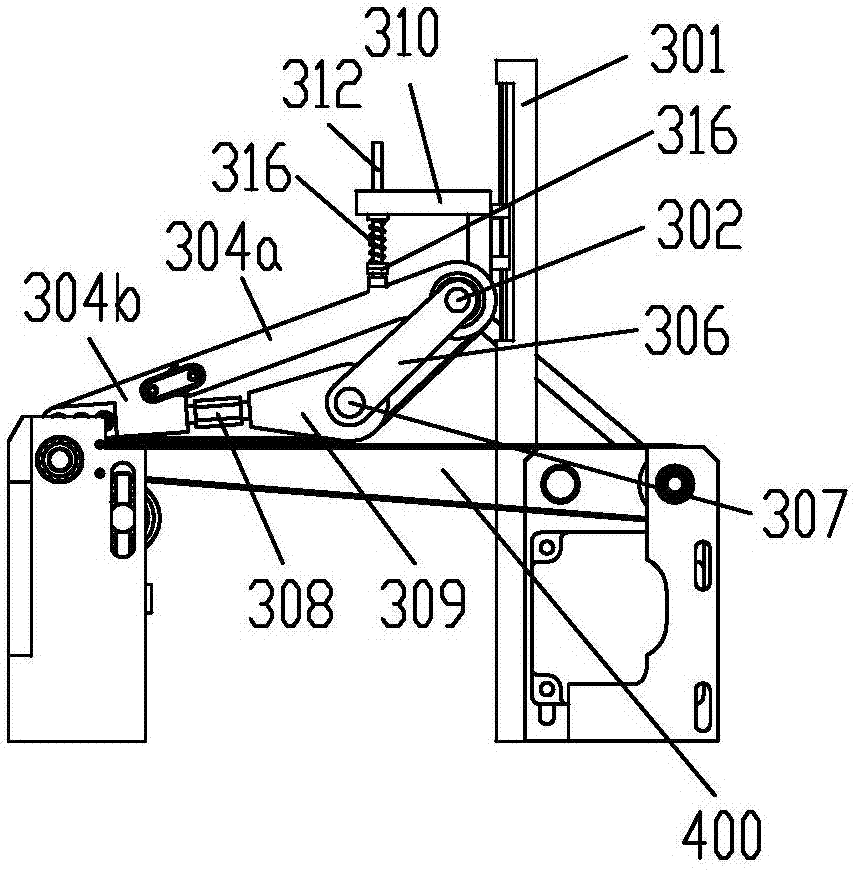

[0019] see figure 1 , figure 2 , a conveying pressure vegetable device, located above the conveyor belt conveying device 400 of the vegetable cutter, the conveying pressure vegetable device includes a conveyor belt pressing structure, the conveyor belt pressing structure is connected with an elastic loading structure. The conveyor-belt pressing structure includes a pressing frame 301 and a driving roller 302. The driving roller 302 is rotatably arranged on the pressing frame 301 through a mount 314, and is connected to the servo motor of the transmission device 400 through a transmission flexible shaft 303. The mounting base 314 and the binder frame 301 are detachably connected by threaded fasteners, and a sliding rail pair that facilitates the height adjustment of the mounting base 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com