Belt roll storage transport rack

A transport rack and belt technology, applied in the field of conveyor belt spare parts, can solve the problems of no storage device, large storage area, irregular storage of spare parts, etc., achieve simple structure, reduce floor space, and ensure the quality of spare parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

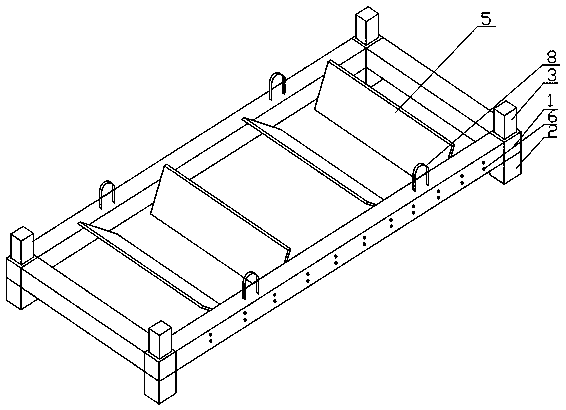

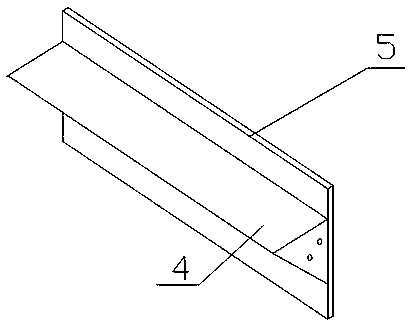

[0022] Example 1, such as figure 1 As shown, a belt roll storage transport frame includes: a bottom frame 1, a bracket cover 3 and a base 2 are respectively fixedly connected to the upper and lower parts of the four corners of the bottom frame 1, and the cross bars on both sides of the bottom frame 1 A plurality of positioning holes 6 are evenly distributed, and a plurality of support plates 4 are fixed by horizontal braces in the underframe 1, and the two ends of the support plates 4 are connected with the positioning holes 6 by bolts, as figure 2 As shown, each support plate 4 is fixedly connected with a sloping plate 5, and two adjacent sloping plates 5 are inclined in opposite directions.

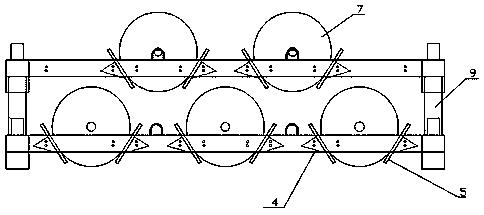

[0023] Such as image 3 As shown, this device can place the belt 7 in the air between two opposite inclined plates 5, and the chassis 1 itself can limit the belt roll 7. When the belt roll 7 is stored, it does not need to be bound and fixed. This device can place the belt Rolls, cabl...

Embodiment 2

[0027] Embodiment 2, based on the technical solution of Embodiment 1, as another embodiment, the present invention sets a plurality of bracket sleeves 3 and bases 2 on the upper and lower parts of each corner of the chassis 1, and sets The number is determined according to the weight of the load.

[0028] The bracket cover 3 , the base frame 1 and the base 2 are connected and fixed through a bracket 9 , and the bracket 9 is sleeved on the bracket cover 3 , passes through the base frame 1 , and is embedded in the base 2 . Support 9 plays the effect of connecting fixed support cover 3, underframe 1 and base 2, and this transportation frame can support and superimpose by support 9, and underframe 1 is increased, also can withdraw support 9 when there is no belt roll 7, will The bottom frames 1 are stacked together, which reduces the footprint of the transport frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com