Sagger waste recycling and circulating system

A recycling system and waste recycling technology, applied in ceramic molding workshops, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of waste of resources, not recycling, etc., and achieve the effect of reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

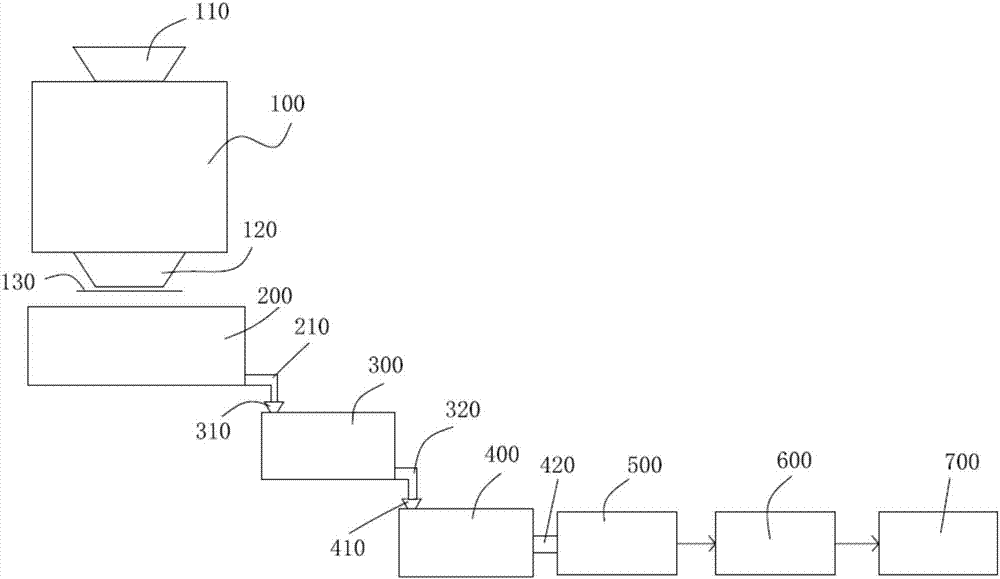

[0017] see figure 1 The shown sagger waste recycling system includes a ball mill 100 , a storage tank 200 , a mud extractor 300 , a mud kneader 400 , a slicing device 500 , a sagger rough body machine 600 and a sagger sintering device 700 .

[0018] The ball mill 100 has a material inlet 110 and a material outlet 120 , and a filter cloth 130 is arranged below the material outlet 120 . The stock tank 200 is disposed under the filter cloth 130 . The feed port 310 of the mud extractor 300 is docked with the discharge port 210 of the stock tank 200 . The feed port 410 of the mud kneader 400 is docked with the discharge port 320 of the mud squeezer 300 . The feed port 510 of the slicing device 500 is connected to the extrusion port 420 of the kneader 400 . The sagger blank machine 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com