Needle threading wheel

A technology of needle and thread and reel, applied in the field of needle and thread, can solve the problems of not fast, the end is not strong enough, and the threading is difficult, and achieves the effect of simple and scientific structure, convenient collection and storage, and great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

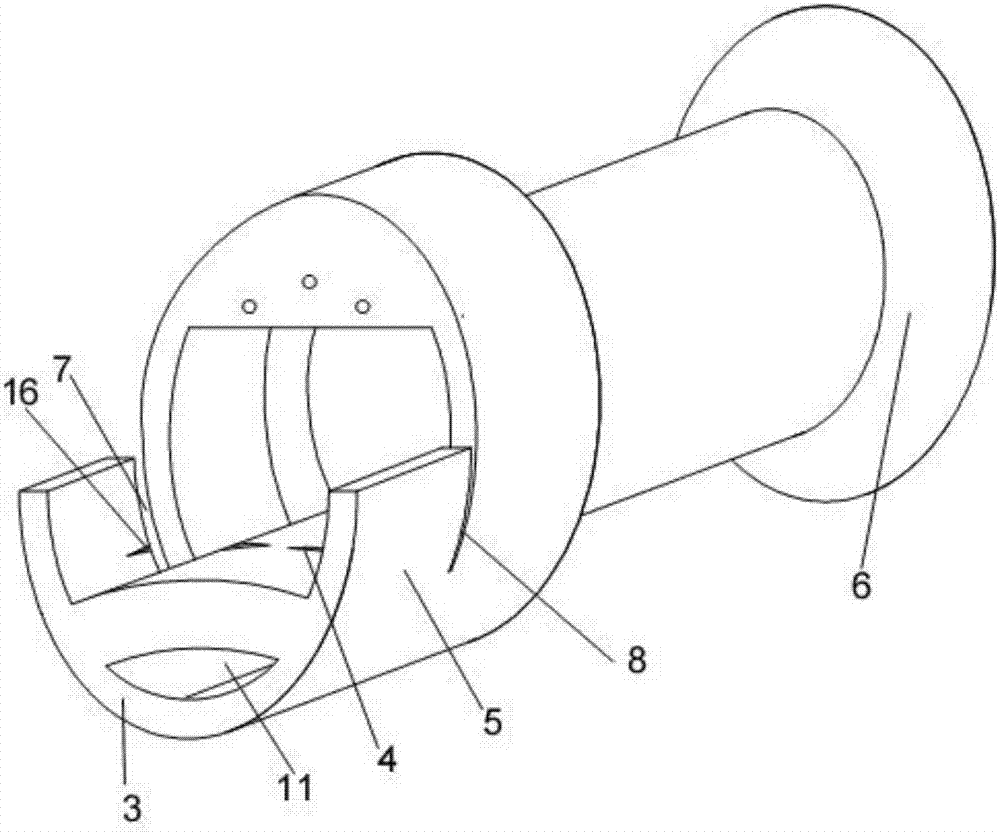

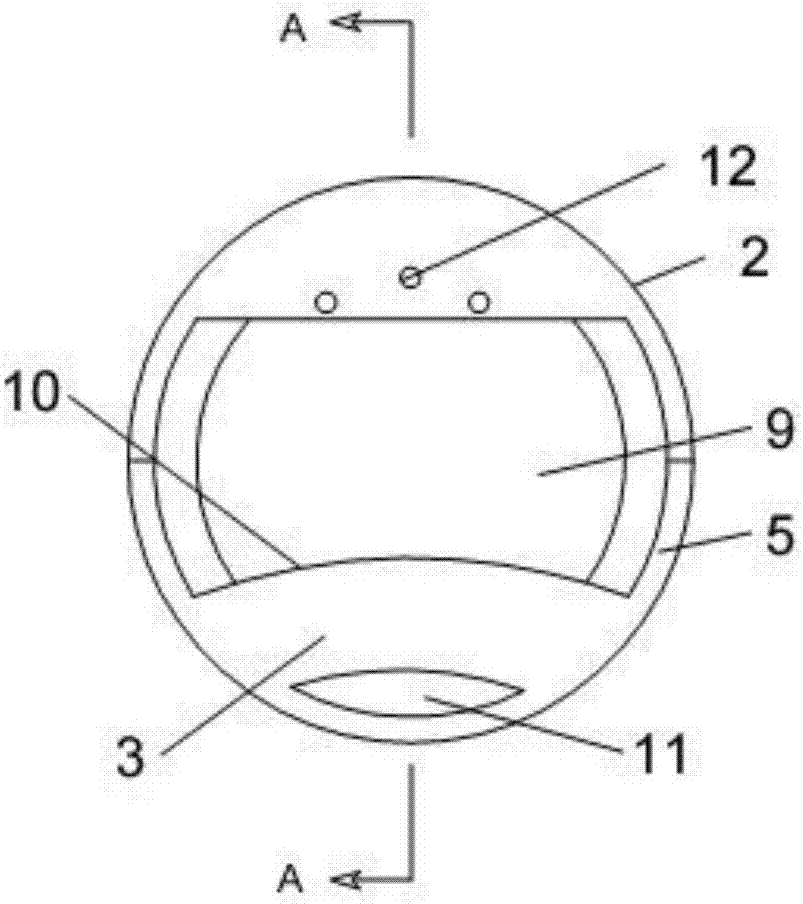

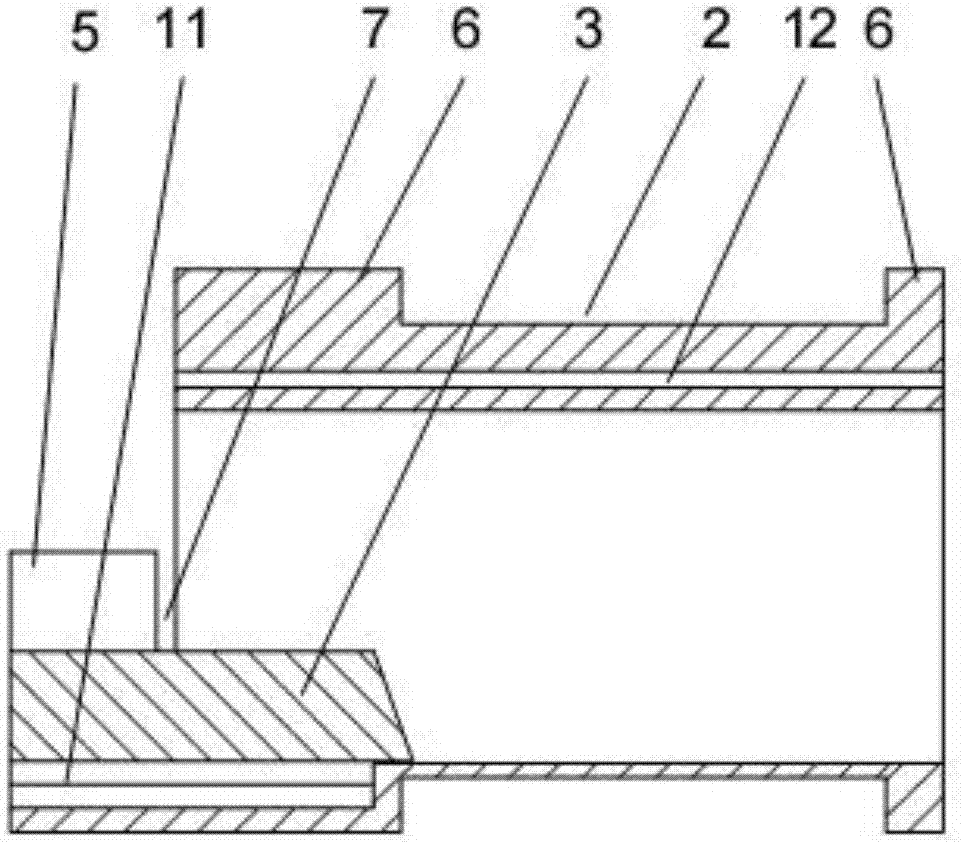

[0029] see Figure 1 to Figure 6 , the needlework wheel 1 of the present embodiment comprises a hollow bobbin 2 and retaining rings 6 located at the left and right ends of the bobbin 2; the center of the retaining ring 6 is provided with a through hole 9 communicating with the hollow of the bobbin 2 and having the same size; it is characterized in that : one of the retaining ring 6 front ends is connected with a section of half-ring extension part 4 used as a needle thread, the bottom part of the half-ring extension part 4 is provided with a soft rubber strip 3 supporting the pinhole 34 laid flat, the soft rubber strip 3 The through hole 9 of the retaining ring 6 extends inward to the hollow of the bobbin 2; the surface of the soft rubber strip 3 is provided with a transverse shallow groove at the junction of the half-ring extension 4 and the retaining ring 6 to provide positioning and limiting functions for the needle thread 32 There are slits for the needle thread 32 to pass...

Embodiment 2

[0034] see Figure 1 to Figure 6, in order to save the material of the soft rubber strip 3 and make the threading action easier and more efficient, this embodiment is further improved on the basis of embodiment 1. The surface of the soft rubber strip 3 is an upwardly arched arc 10 . A gap 11 is provided between the bottom of the soft rubber strip 3 and the inner wall of the half-ring extension 4 to strengthen the elastic movement space of the soft rubber strip 3 . The top wall of the retaining ring 6 that is connected with the half-ring extension 4 is provided with 3 needle hiding holes 34 that are longitudinally arranged and extend to the hollow of the bobbin 2. The shape and size of the needle hole 34 are similar to those of the sewing needle 33. match.

Embodiment 3

[0036] see Figure 7 ~ Figure 8 In order to make the needle threading wheel 1 more stable when threading the needle, prevent it from swinging left and right, improve the efficiency of needle threading, and at the same time cut off the needle thread 32 conveniently, so that the threading action can be carried out more easily and efficiently. On the basis of further improvement, grooves 13 are provided on the left and right sides of the retaining ring 6 and the connected half-ring extension 4, and the grooves 13 are provided with supports that can rotate to the side of the retaining ring 6 and limit the rolling of the needle thread wheel 1 Pin 14 ensures that the sewing wheel 1 position remains stable when the pinhole 34 moves back and forth. The side wall of the wire inlet groove 7 is provided with a V-shaped secant groove 16 , and the inner wall of one side of the V-shaped secant groove 16 has a cutting edge 17 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com