A transparent soil model test device and test method for simulating soil lateral movement

A model test device and transparent soil technology, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of low visibility and measurement of pile-soil interaction, achieve small device size, convenient test operation, Reasonable system settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

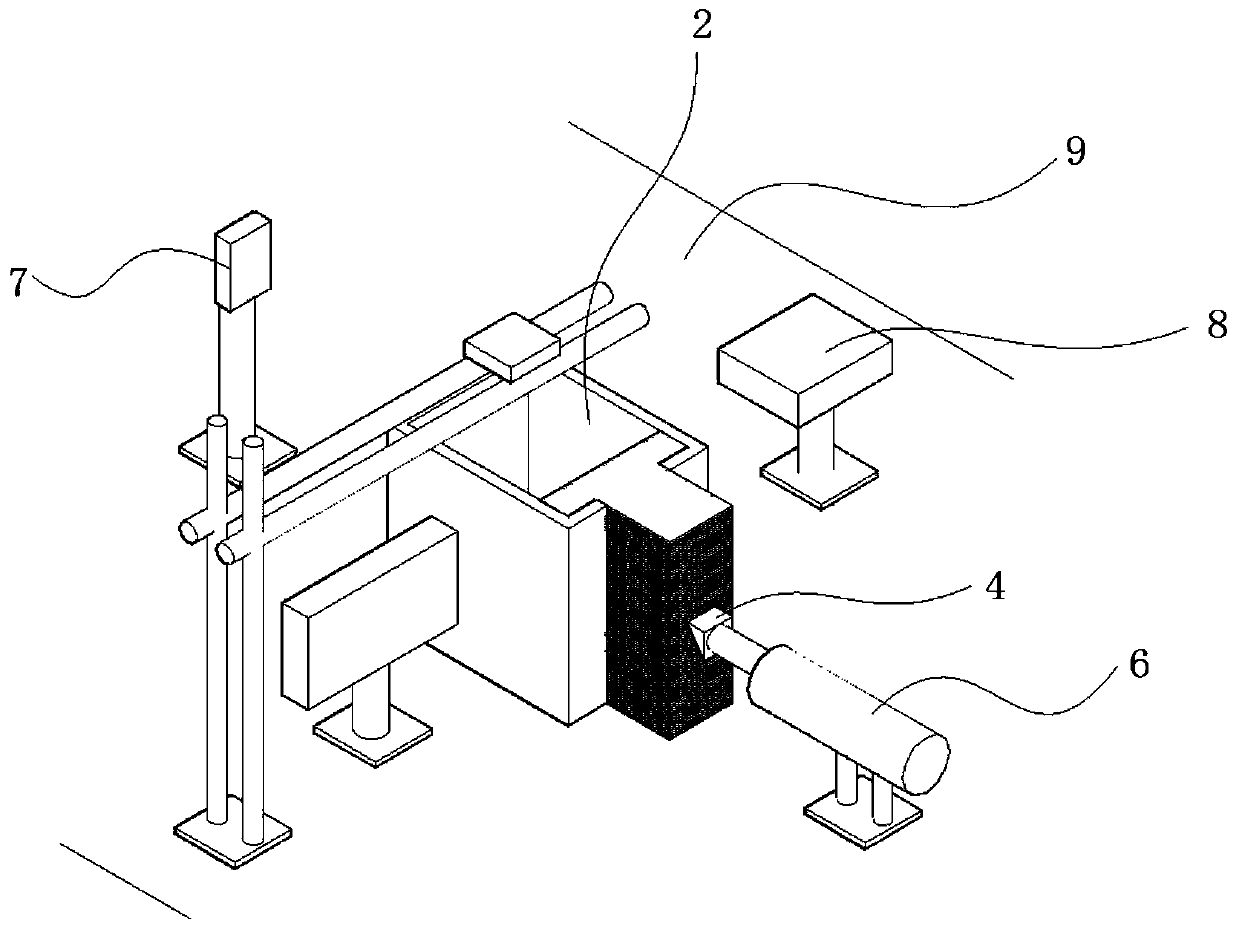

[0037] This embodiment discloses a transparent soil model test device for simulating the lateral displacement of soil, which includes a transparent model box 1 that can be fixed on an optical platform 9, a T-shaped block 3 and a loading block 4.

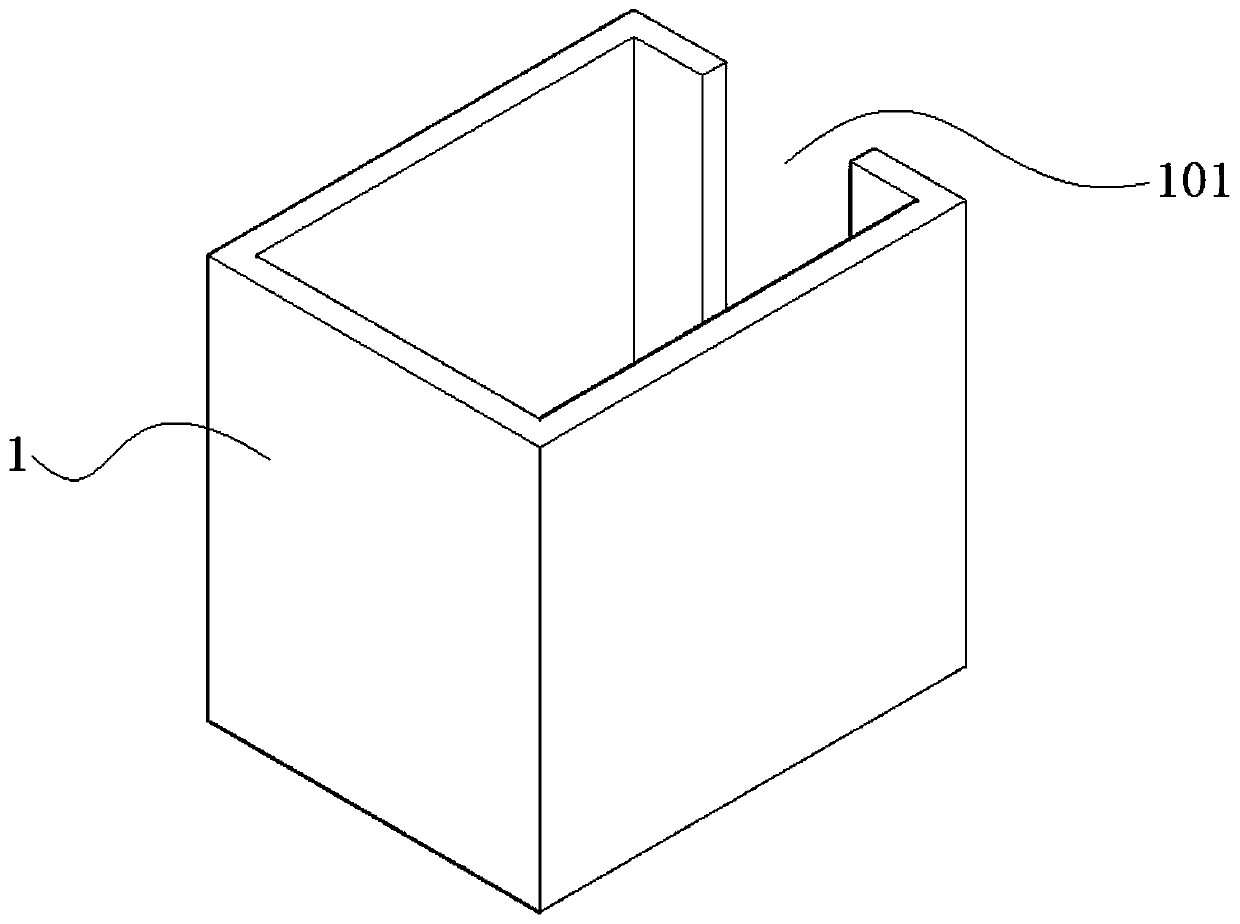

[0038] See figure 1 The transparent model box 1 as a whole is a rectangular box with an open upper end and a hollow inside. There is a rectangular notch 101 on one side of the rectangular box. The transparent model box 1 is made of organic glass.

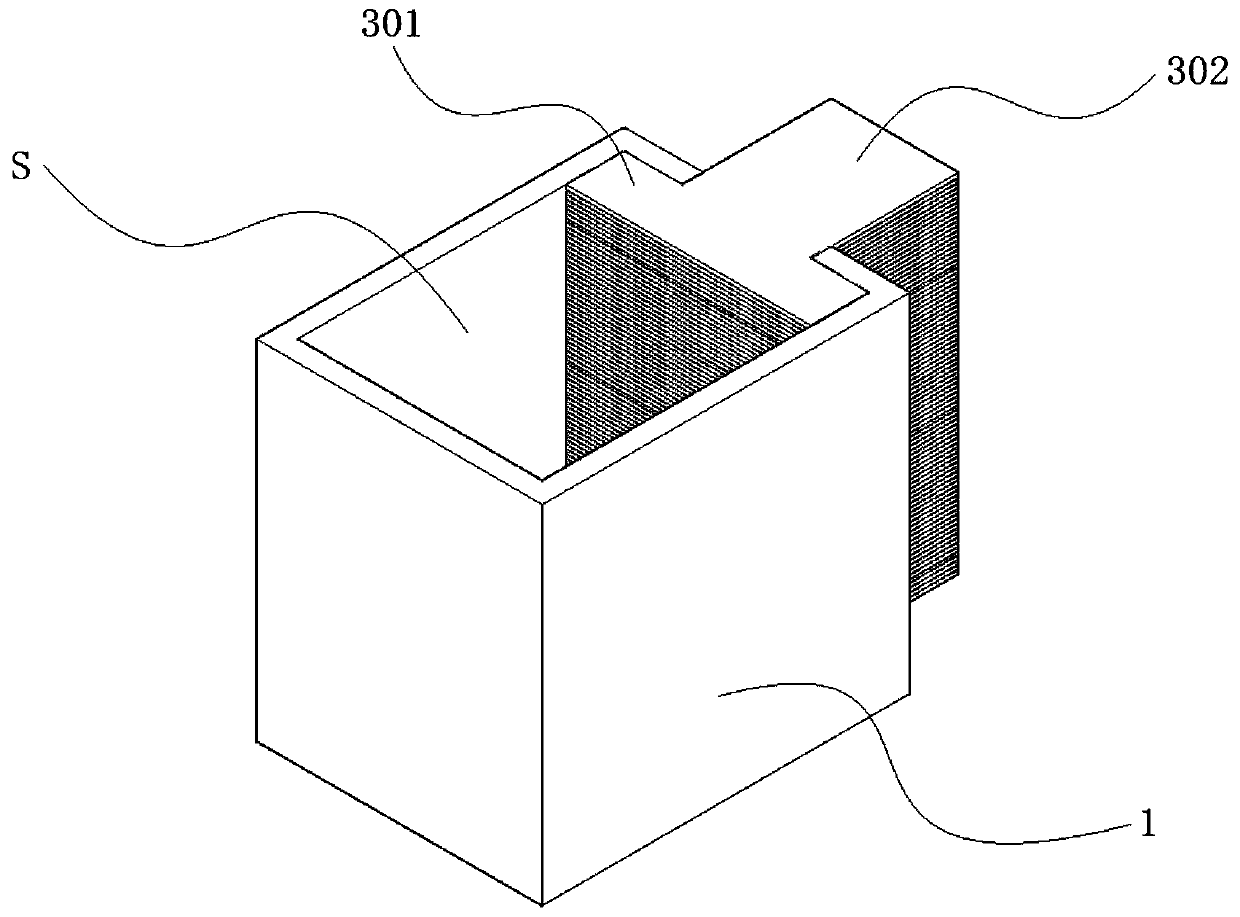

[0039] See Figure 5 versus figure 2 , The cross section of the T-shaped block 3 is T-shaped. The T-shaped block 3 includes a rectangular parallelepiped flange portion 301 and a rectangular parallelepiped web portion 302 that are perpendicular to each other. The T-shaped block 3 is formed by stacking and combining multiple T-shaped sheet-like plates. The T-shaped block 3 is embedded on the notch side of the transparent model box 1. The flange portion 301 is located in the inner cavity of ...

Embodiment 2

[0045] This embodiment discloses a test method related to the above test device, including the following steps:

[0046] 1) Make transparent model box 1, T-shaped sheet plate and loading block 4 according to the designed size, and scrub the side wall of transparent model box 1.

[0047] 2) Stack the T-shaped sheet plates on the notch of the transparent model box 1 to form a T-shaped block 3.

[0048] 3) Place the transparent film bag 5 in the semi-enclosed space S.

[0049] 4) Prepare transparent soil 2 in the transparent film bag 5 to the design height. During the preparation process, the model pile is buried in the design position. After preparation, let it stand for 24 hours. Wherein, the preparation method of the transparent soil 2 is: pour the prepared mixture of white oil and n-dodecane into the transparent film bag 5. The transparent film bag 5 is in close contact with the side wall of the semi-enclosing space S without wrinkles. Then, fused silica sand solid particles with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com