Visual measurement method for temperature distribution of annular combustion field

A technology of temperature distribution and measurement method, which is applied in chemical analysis by means of combustion, application of thermometers, thermometers, etc., can solve problems such as increased calculation amount, unconfirmed convergence, and inability to simultaneously give dual-mode distribution information, etc., to achieve Good adaptability and fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

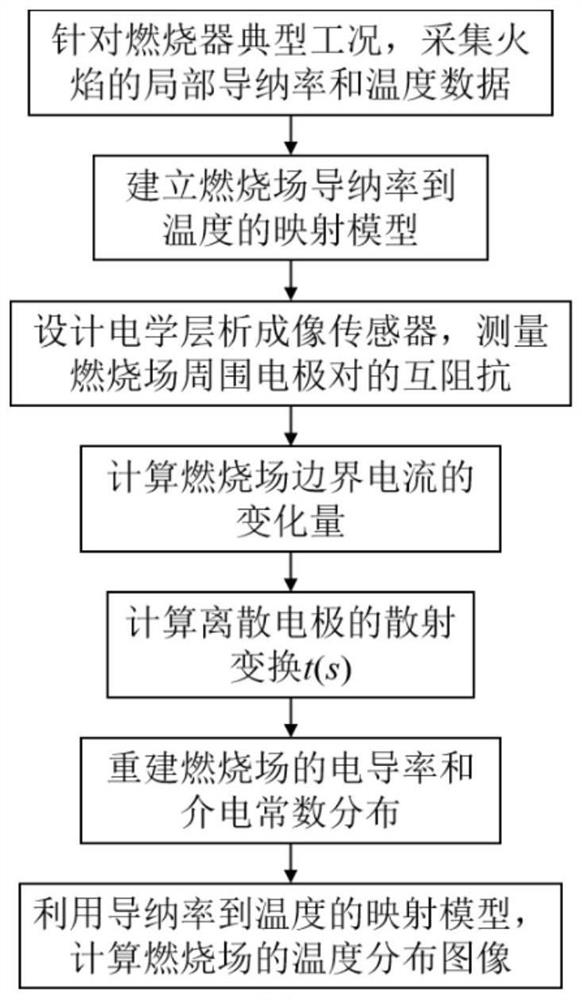

[0073] The invention is a visual measurement method for the temperature distribution of an annular combustion field, and the specific implementation method is as follows:

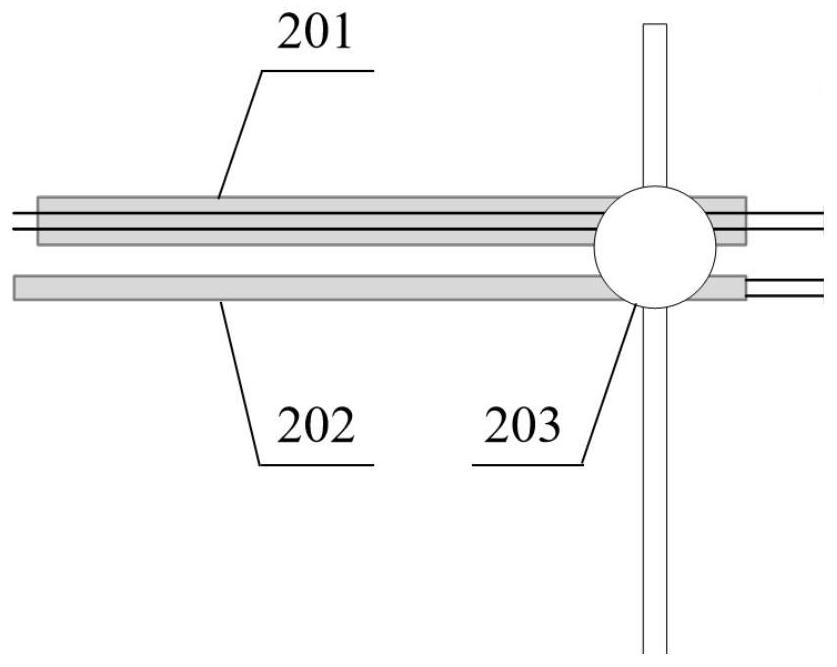

[0074] Step 1: For the typical working conditions of the blunt body turbulent flow burner, increase the intake flow rate of propane fuel from 30mL / min to 50mL / min with a step size of 10mL / min, and increase the intake flow rate of air from 100mL / min To 200mL / min, the step size is 50mL / min, use the ion current probe and thermocouple probe to collect the local admittance and temperature data of the combustion field, such as figure 2 As shown, the ion current probe 201 and the thermocouple probe 202 are connected by a direction-adjustable fixture 203 and fixed on the two-dimensional precision displacement stage, and the impedance of the ion current probe electrode pair is collected by the impedance measurement hardware system connected thereto. The temperature difference caused by the front end of the thermoco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com