Wet type four-wheel drive transfer case structure and tractor

A transfer case, wet-type technology, applied in the field of tractors, can solve problems such as complicated operation, and achieve the effect of simple and light operation and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

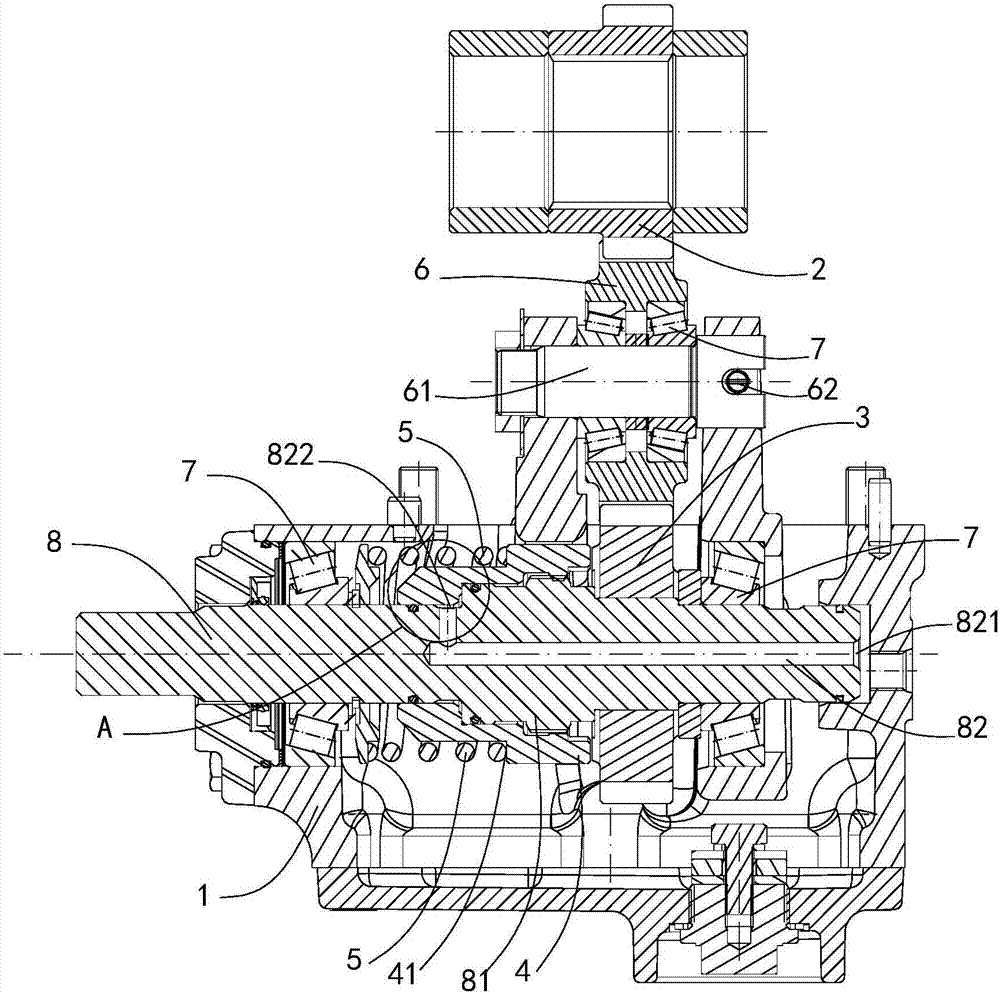

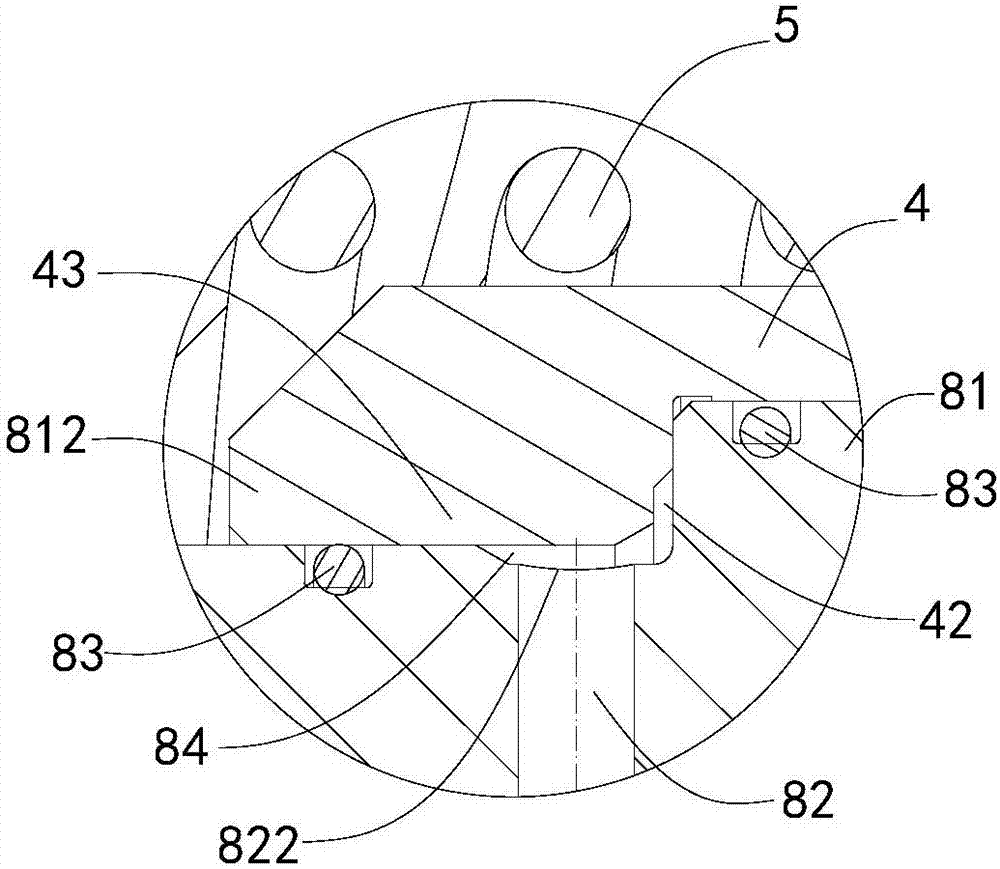

[0030] Such as figure 1 As shown, a wet four-wheel drive transfer case structure of this embodiment includes a housing 1, an input gear 2, an output gear 3, an output shaft 8, a tooth nest 4 and a return spring 5, and the input gear 2 and the output The gears 3 are all installed in the housing 1 and engaged in transmission, the output shaft 8 is rotatably connected to the housing 1 and passed through the center of the output gear 3, the output shaft 8 is connected to the output The gears 3 are coaxially arranged and have a clearance fit; the tooth nest 4 is sleeved on the output shaft 8 and splined with it, and one end of the tooth nest 4 meshes with an end surface of the output gear 3; The return spring 5 is arranged along the axial direction of the output shaft 8 and one end abuts on the tooth socket 4 , and the other end abuts on the inner side wall of the housing 1 .

[0031] Such as figure 1 As shown, an oil passage 82 is provided in the output shaft 8, and the oil outl...

Embodiment 2

[0043] A tractor includes the wet four-wheel drive transfer case structure as described above. The tractor of this embodiment is engaged and disengaged by hydraulically controlling the four-wheel drive, and is easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com