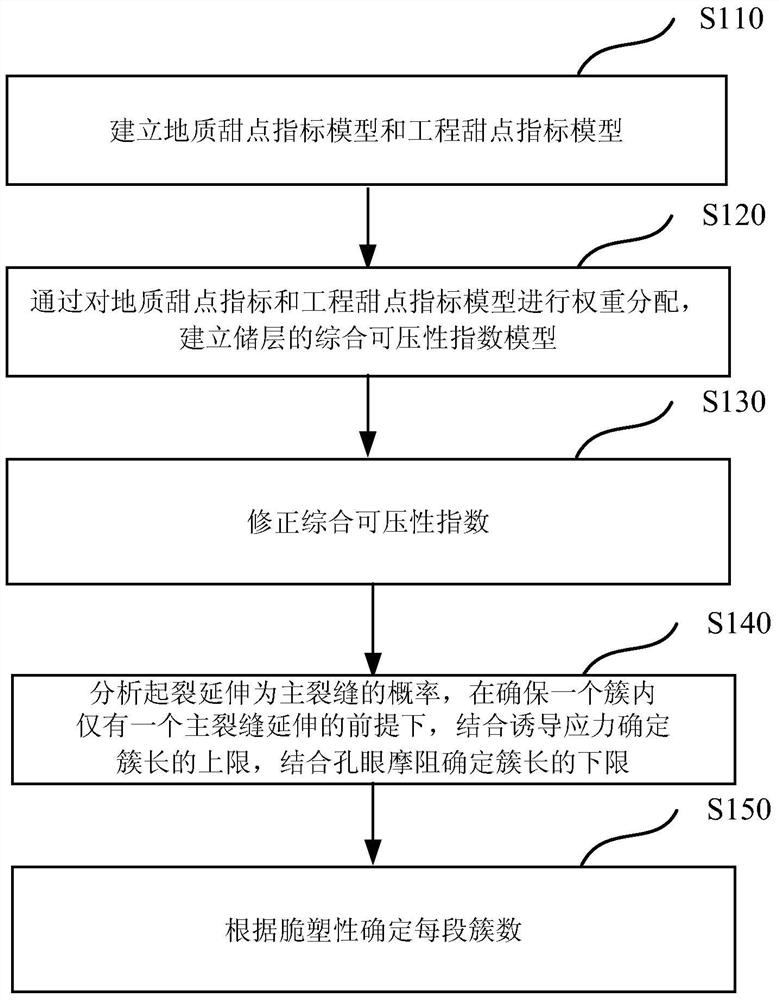

A Method for Optimizing the Perforation Scheme of Staged Fracturing Clusters in Horizontal Wells

A technology of staged fracturing and optimization method, which is applied in earth-moving drilling, wellbore/well components, data processing applications, etc. Achieve scientific and reasonable design scheme, improve construction effect, and reduce the effect of ineffective cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

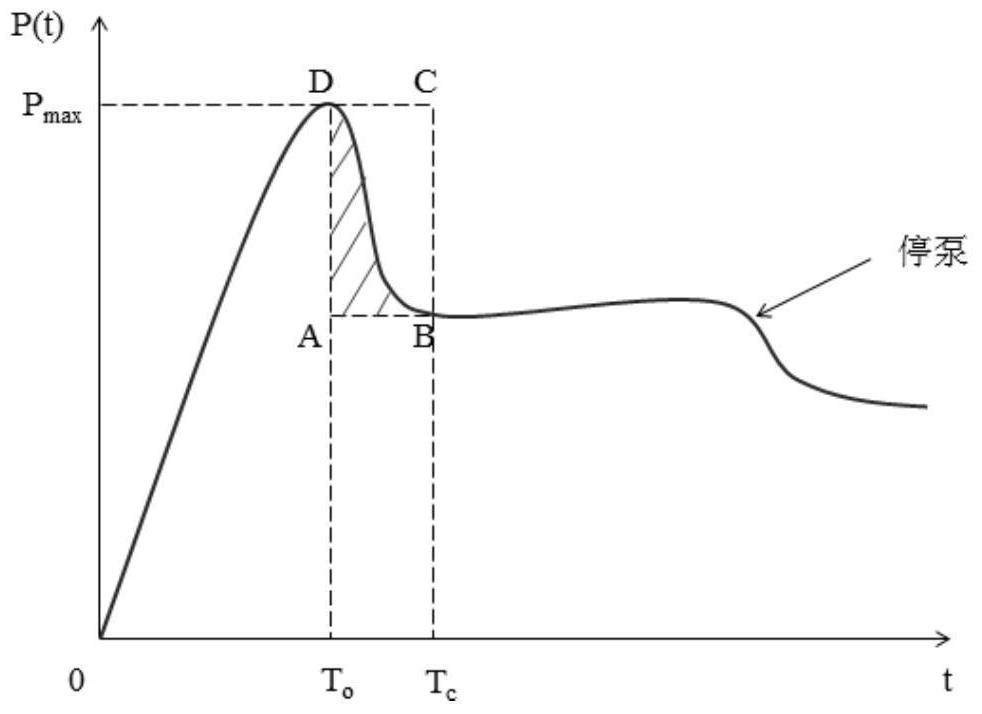

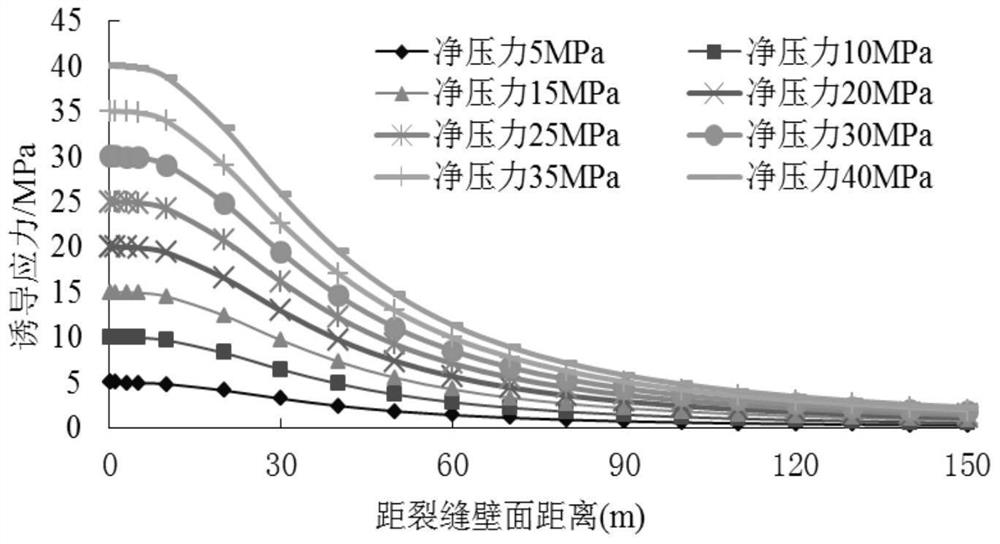

Method used

Image

Examples

Embodiment

[0085] The present invention is applied in the optimal design of the staged fracturing cluster perforation scheme of a shale gas horizontal well in southeastern Sichuan. The vertical depth of the well is 2402m, the measured depth is 4100m, and the horizontal section is 1530m long. Through the method provided by the present invention, optimize the cluster perforation position, and obtain the optimal cluster perforation parameters as follows: design perforation 50 clusters, wherein the first section has two clusters in each section, and each cluster is 1.5m; the 2nd to 17th sections are in each section Three clusters, each cluster 1m; aperture 9.5mm. The field implementation successfully solved technical problems such as the high proportion of ineffective and low-efficiency fractures in shale gas reservoirs and the limited potential of fracturing stimulation. The production profile logging interpretation of the well was performed, and the production contribution rate of the frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com