Current carrier and design method thereof

A current carrier and design method technology, applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve problems such as system reliability deterioration, achieve the effects of improving stability, ensuring electrical connection performance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

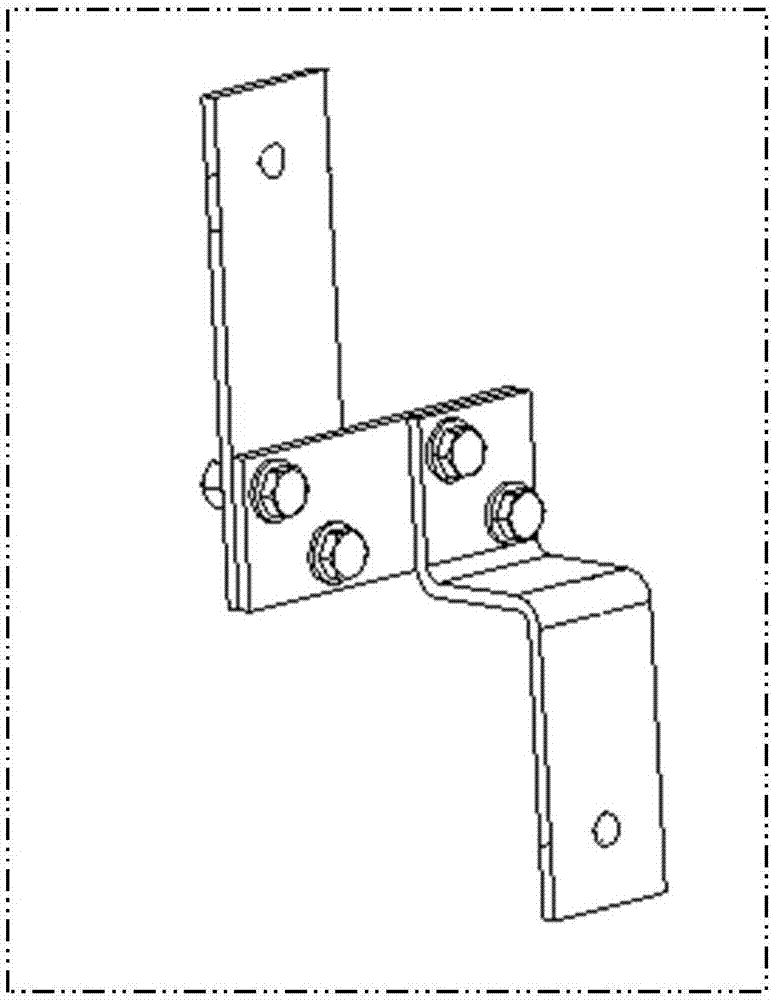

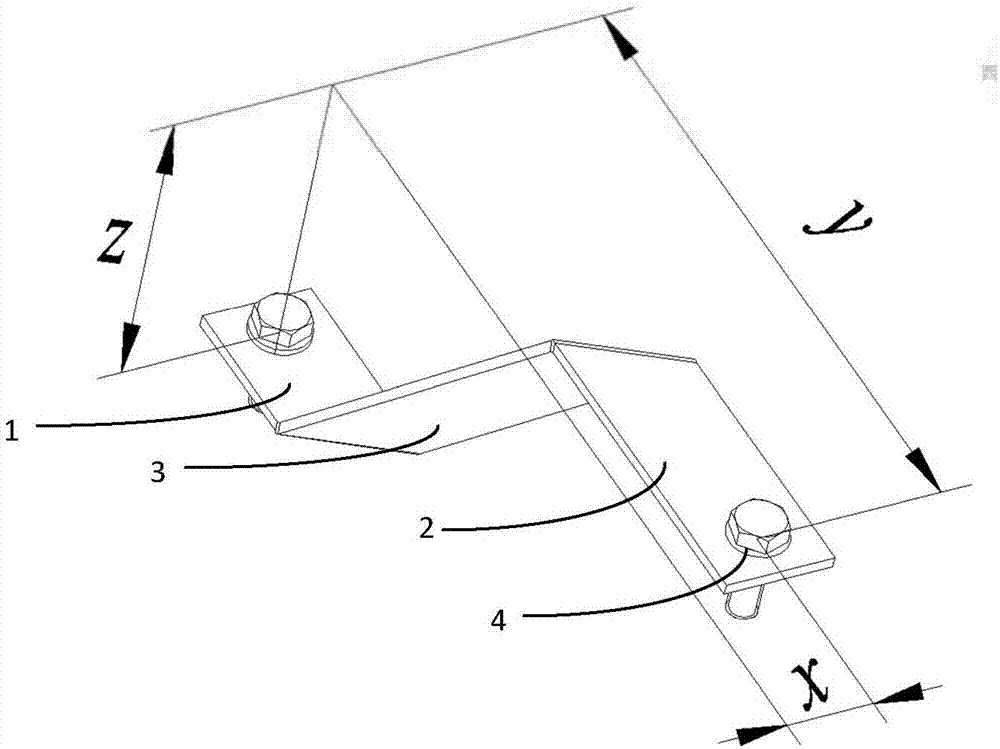

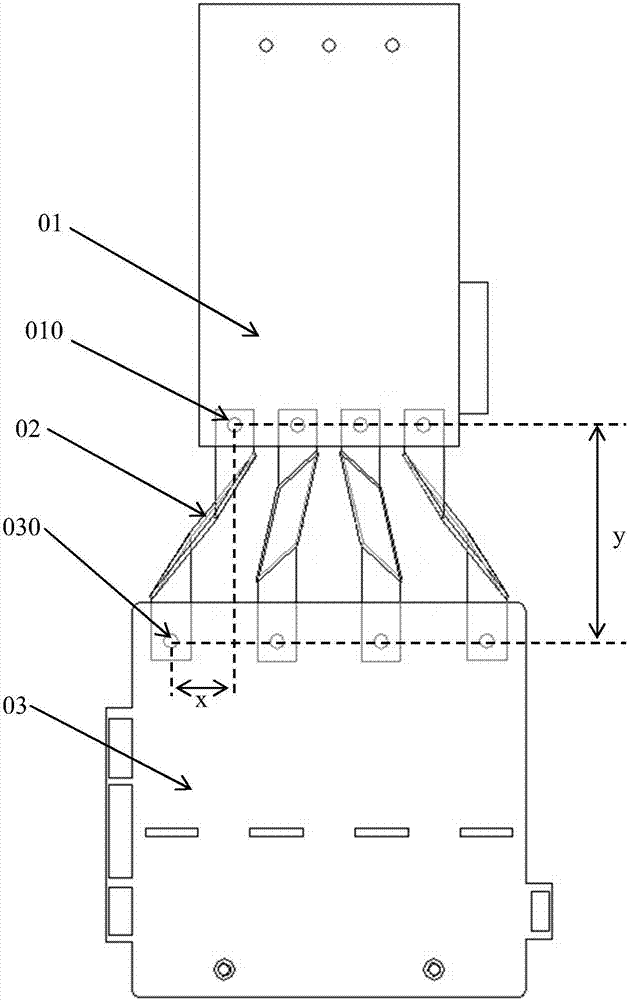

[0023] Such as figure 2 As shown, the current carrier includes a flat metal strip, and the metal strip includes a first bent portion 1, a second bent portion 2 and a middle oblique section 3, the first bent portion 1 and the second bent portion 2 are respectively Located at both ends of the middle oblique section 3, the middle oblique section 3 includes a front and a back, the first bending part 1 bends toward the front of the middle oblique section 3, and the second bending part 2 obliquely toward the middle The back of the bending section 3 is bent, and the first bending part 1 and the second bending part 2 are both provided with through holes 4, and the bolts matching the through holes 4 and the connection points are also drawn in the figure. Other commonly used fixing methods.

[0024] The junction of the first bending part 1 and the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com