A green environmental protection paint spraying machine

A green and environmental protection spraying machine technology, applied in spray booths, spraying devices, etc., can solve the problems of no harmful gas adsorption function, harm to human health, uneven spraying, etc., to achieve convenient gas collection, reduce labor intensity, and prevent environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

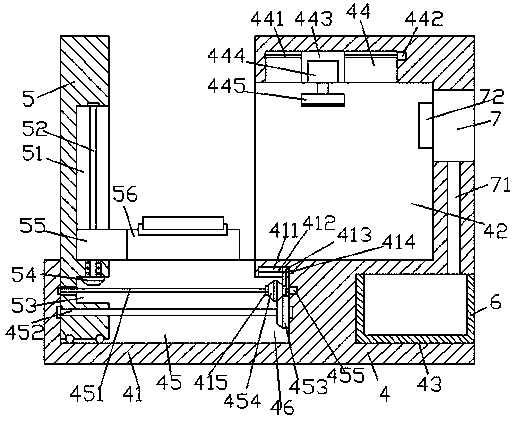

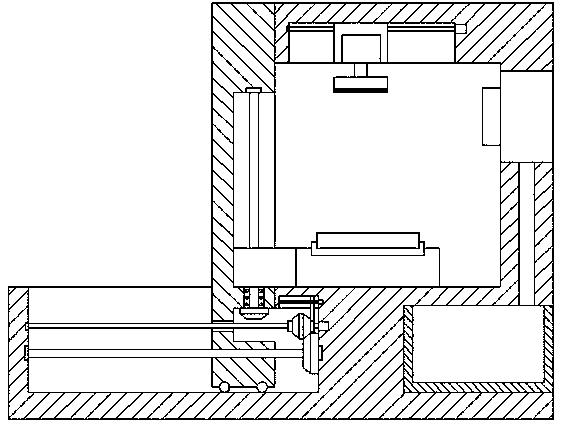

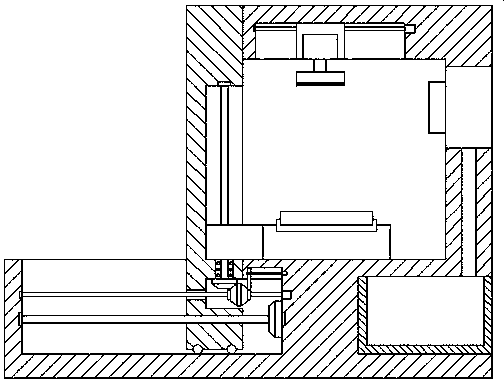

[0025] like Figure 1-Figure 8 As shown, a kind of green environmental protection paint spraying machine of the present invention, comprises the frame body 4 that is provided with transfer seat 41 on the left side, is provided with spraying chamber 42 in the left end face of described frame body 4 on the upper side of described transfer seat 41, The inner upper wall of the spray chamber 42 is provided with a first sliding groove 44, the first sliding groove 44 is provided with a first screw rod 441, and the first screw rod 441 is screw-fitted and connected with Spraying sliding block 443, described transfer seat 41 is provided with the second sliding groove 45 that elongates to set left and right, described frame body 4 on the right side of described transfer seat 41 is provided with embedded groove 46, and described embedded The left end of the loading groove 46 is connected with the elongated tail end on the right side of the second sliding groove 45, and the inner wall on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com