Exhaust device and heat treatment system

A technology of an exhaust device and a heat treatment furnace, which is applied in the field of heat treatment, can solve problems such as incomplete oil fume treatment, and achieve the effect of alleviating incomplete oil fume treatment and good oil fume purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

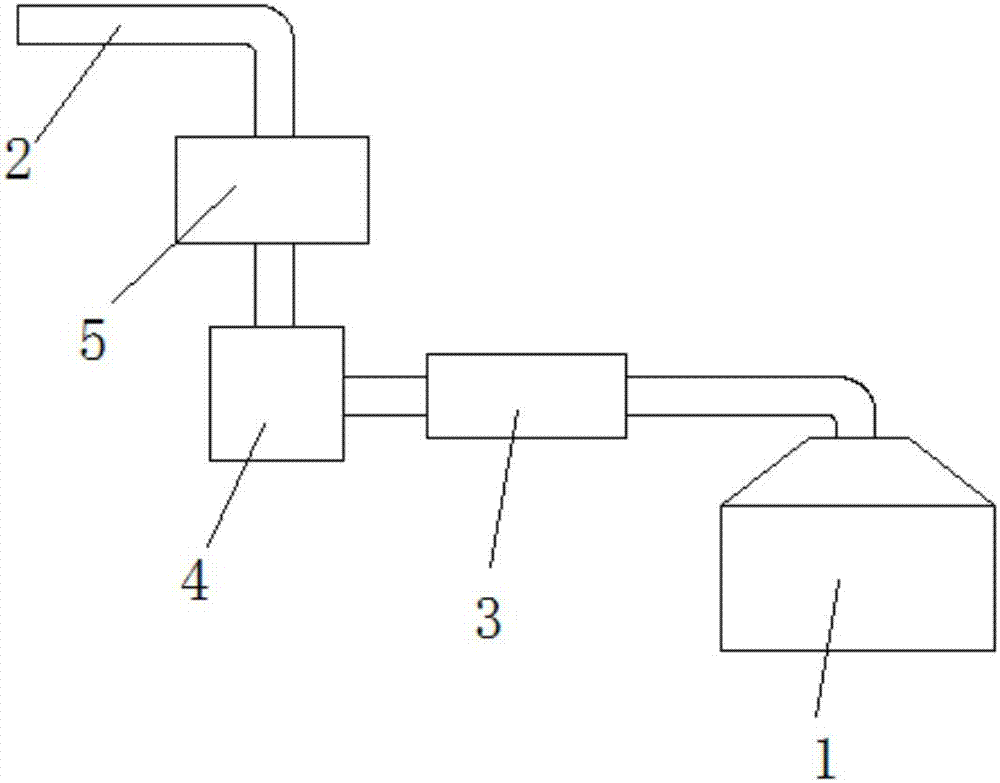

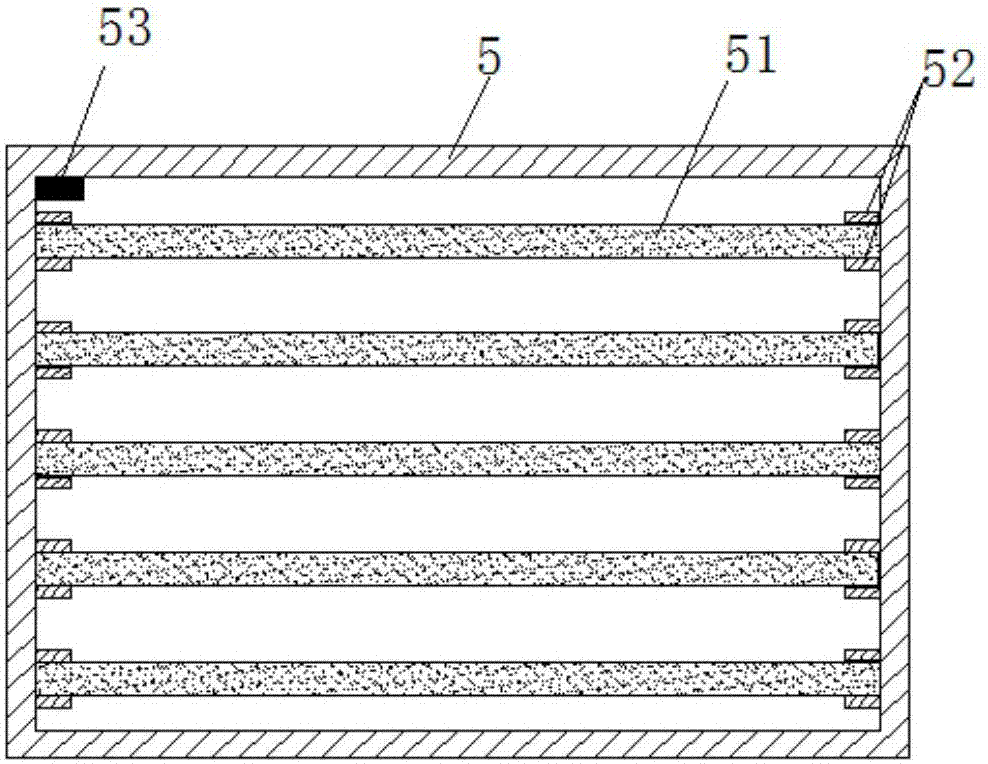

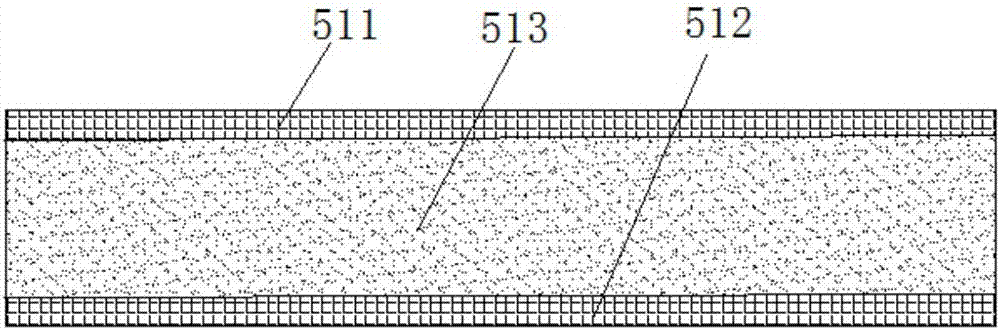

[0036] Such as figure 1 As shown in -4, the exhaust device provided by Embodiment 1 of the present invention includes: a fume hood 1 arranged on the heat treatment furnace, and a smoke exhaust pipe 2 is connected to the top of the fume hood 1; There are a fume purifier 3, a fume conveying device 4 and an adsorption device 5; the adsorption device 5 is provided with a detachable activated carbon filter element 51.

[0037] The exhaust device provided by the present invention includes: a fume hood 1 arranged on the heat treatment furnace, a smoke exhaust pipe 2 is connected to the top of the fume hood 1; a fume purifier 3, a fume conveying pipe 2 are arranged in sequence along the flow direction of the fume The device 4 and the adsorption device 5; the adsorption device 5 is provided with a detachable activated carbon filter element 51. When in use, the oil fume is first filtered through the oil fume purifier 3, and a large amount of oil molecules are filtered and collected; th...

Embodiment 2

[0059] The heat treatment system provided in Embodiment 2 of the present invention includes the exhaust device provided in Embodiment 1.

[0060] In the heat treatment system provided by the embodiment of the present invention, the workpiece to be heat treated advances along the running direction of the conveying device. When the workpiece falls into the oil tank for heat treatment, the oil fume generated by the heat treatment will emerge from the oil tank. The outside of the conveying device and the outside of the oil tank, so the oil fume is not easy to overflow into the workshop environment from the fume hood 1 provided by the present invention. The oil fume is pumped away to reduce the probability of oil fume overflowing through the opening of the shell at the entrance of the conveying device. The oil fume is first filtered through the oil fume purifier 3 to filter and collect a large number of oil molecules; after passing through the oil fume conveying device 4, the smoke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com