Positioning and clamping mechanism for machining outer circle of brake

A technology for positioning and clamping and braking, which is applied to metal processing mechanical parts, positioning devices, clamping devices, etc., can solve the problems of excessive braking surface of the brake workpiece and uneven braking gap, and achieve the elimination of gaps, installation and disassembly. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

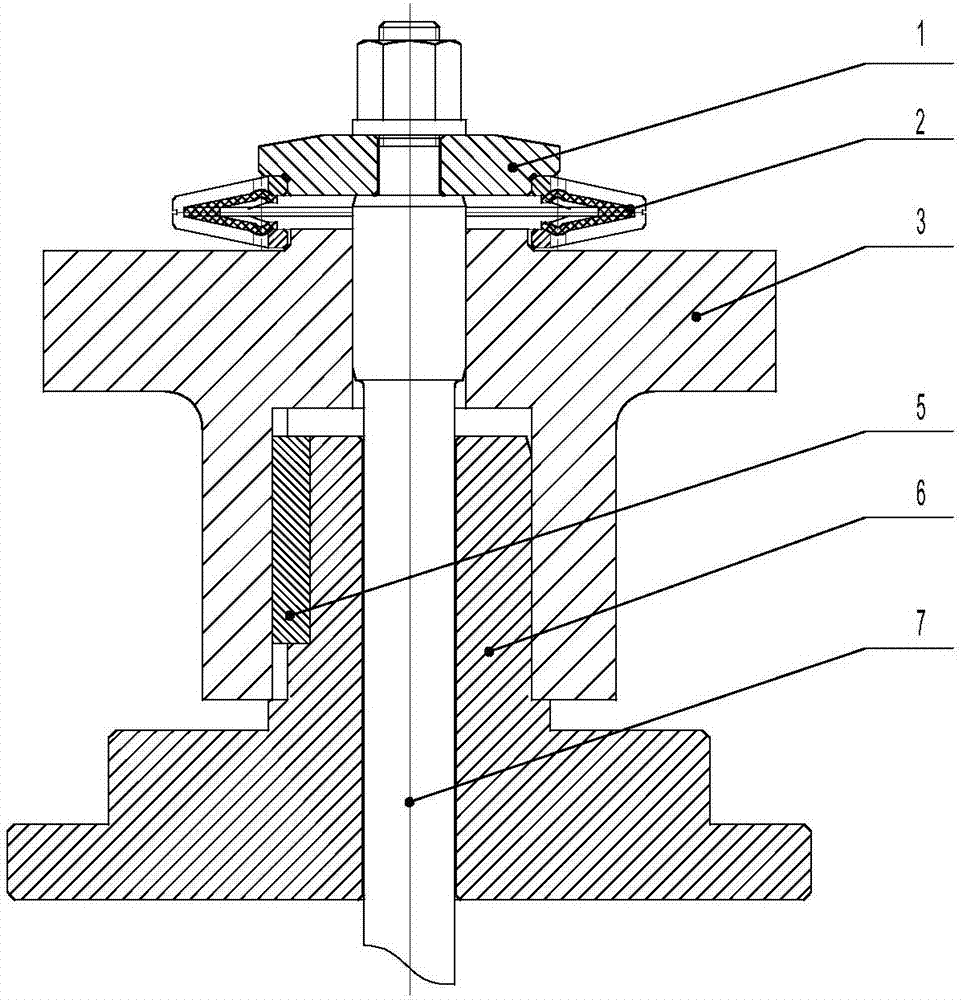

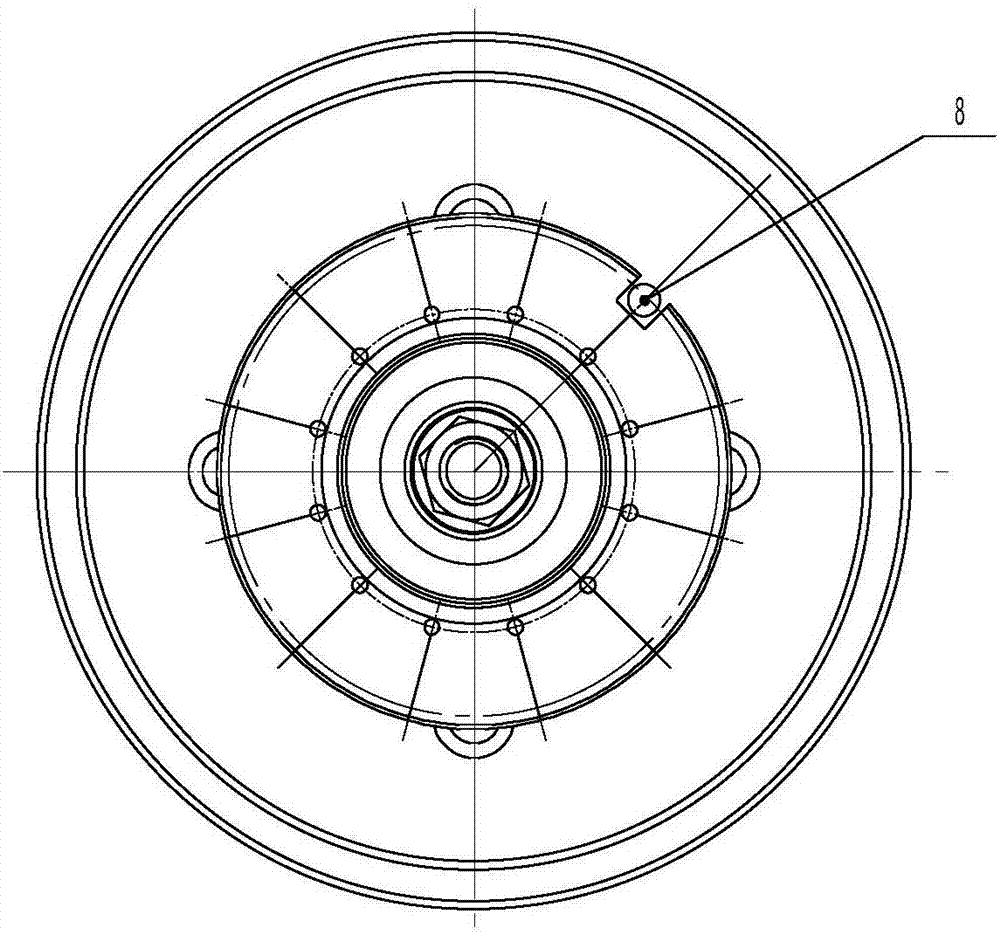

[0034] A positioning and clamping mechanism for brake external machining, see Figure 1 to Figure 2 , including the pressure plate 1, the spring expansion piece 2, the positioning connecting seat 3, the base 6, the tie rod 7, the base 6 is connected with the machine tool, the lower end of the positioning connecting seat 3 is sleeved on the upper end of the base 6, and is connected to the base through the key 5. The seat 6 is fixedly connected; the upper end face of the positioning connection seat 3 is connected with the workpiece 4, and the upper end face of the positioning connection seat 3 is provided with a positioning step II; the pressure plate 1 is located above the positioning connection seat 3, and the bottom of the pressure plate 1 is provided with There is a positioning step I, and the spring expansion piece 2 is sleeved between the positioning step I and the positioning step II. One end of the tie rod 7 is fixed on the pressure plate 1 by a fastener - a nut, and the...

Embodiment 2

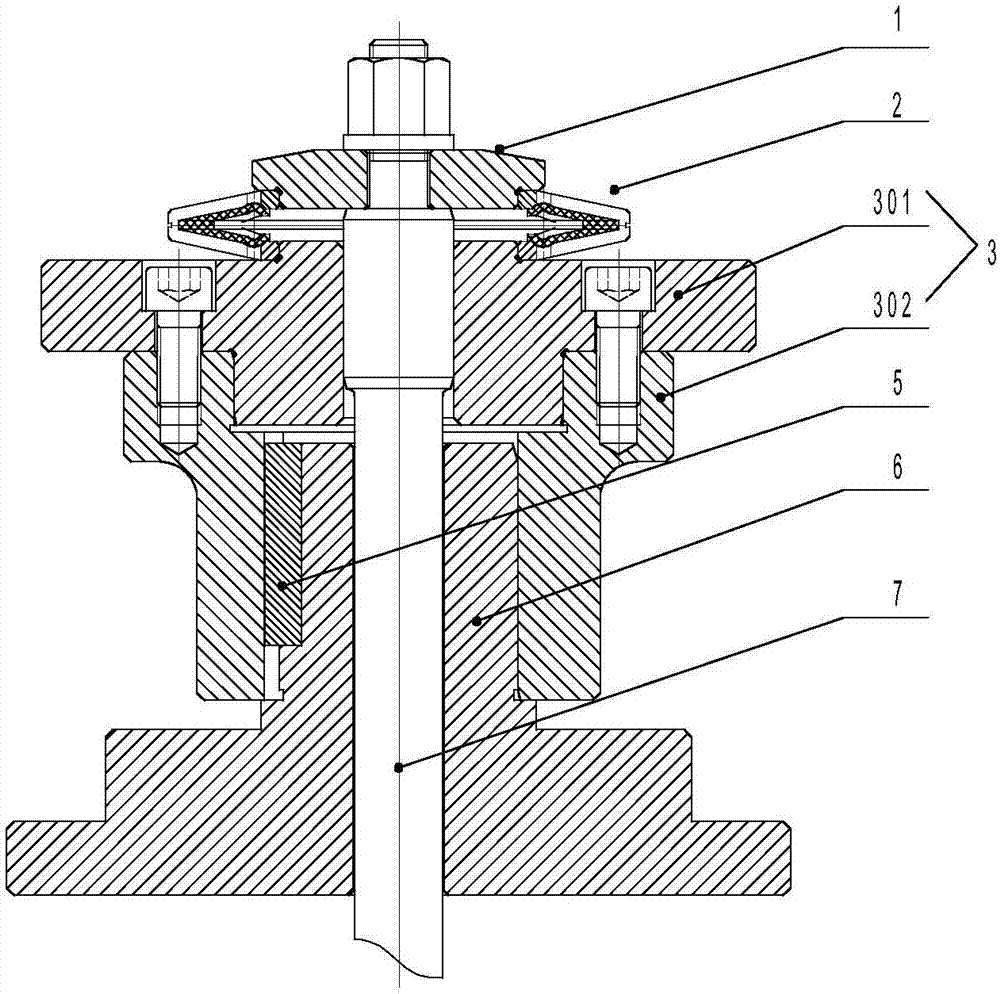

[0036] A positioning and clamping mechanism for brake external machining, see Figure 3 to Figure 4 , including the pressure plate 1, the spring expansion piece 2, the positioning connection seat 3, the base 6, the pull rod 7, the base 6 is connected with the machine tool, the positioning connection seat 3 includes a positioning seat 301, a connecting base 302, and the upper end of the positioning seat 301 The end face is connected with the workpiece 4, and the upper end face of the positioning seat 301 is also provided with a positioning step II. The positioning seat 301 and the connecting base 302 are connected together by fastener bolts; the connecting base 302 is sleeved on the base 6, and is fixedly connected with the base 6 through the key 5; the pressure plate 1 is located above the positioning seat 301, the bottom of the pressure plate 1 is provided with a positioning step I, and the spring expansion piece 2 is sleeved on the positioning Between step I and positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com