A kind of preparation method of single particle size polymer micro-nano particles

A technology of micro-nanoparticles and polymers, applied in the field of preparation of micro-nanoparticles, can solve problems such as low output, inability to produce large-scale continuous production, easy blockage of pipelines or liquid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

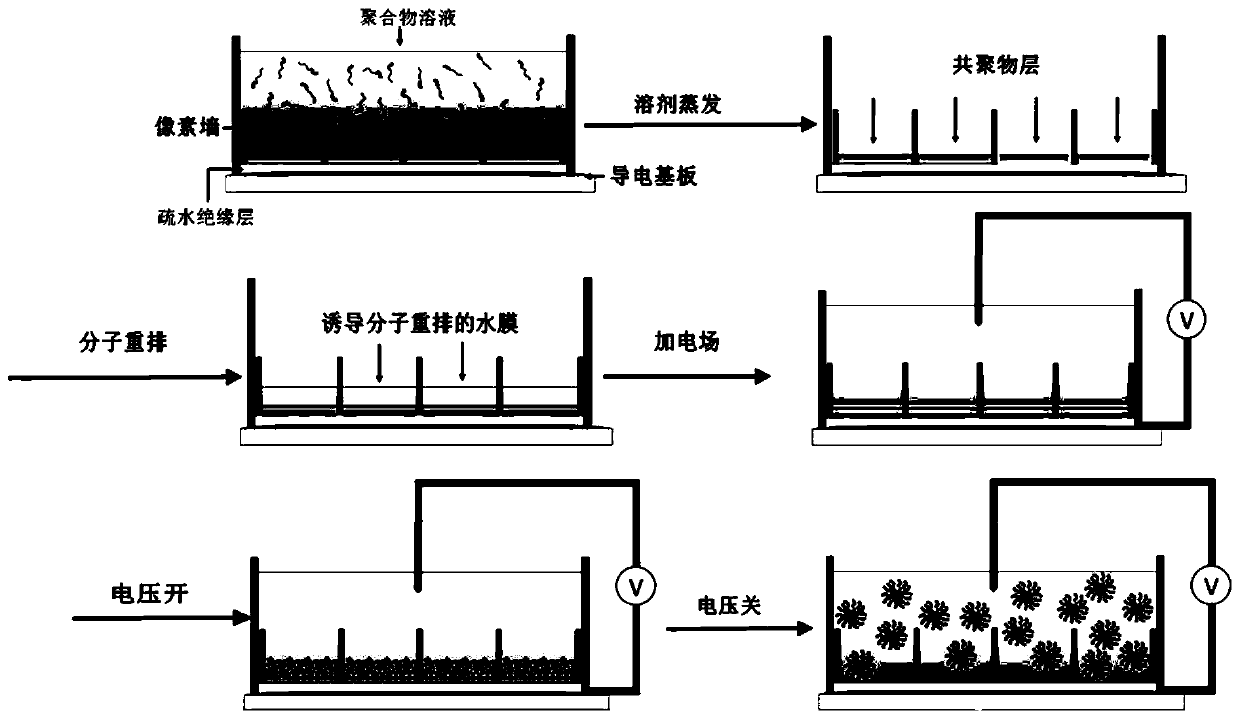

Method used

Image

Examples

Embodiment 1

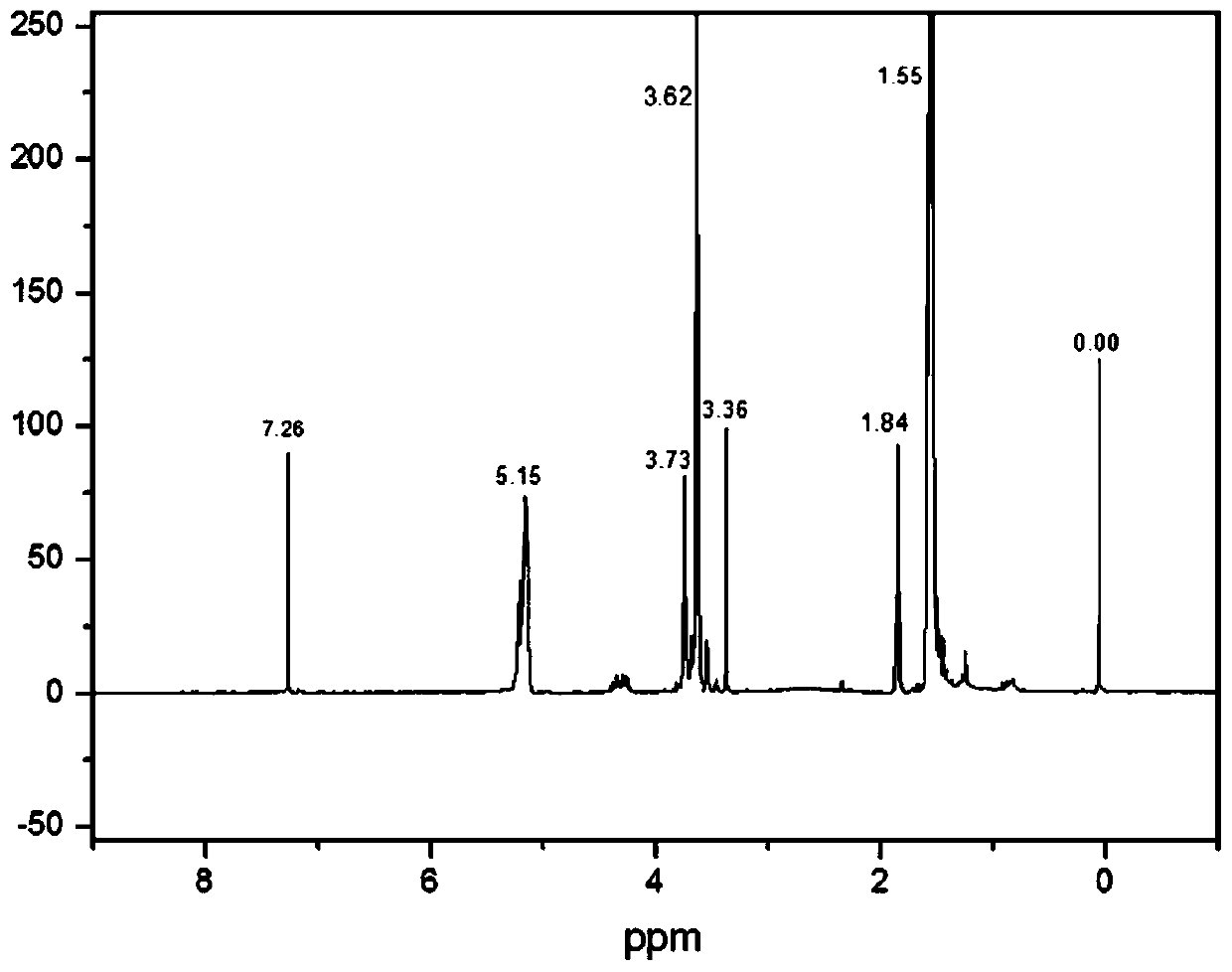

[0041]In the study of polymer self-assembly, polyethylene glycol-polylactic acid block copolymers are the most typical, because the main chain is soft and easy to assemble.

[0042] Take 1.000g CH 3 O-PEG 1000 -OH in a 50mL three-neck reaction flask. Dry under vacuum at 60°C for 2 hours. After cooling to room temperature, add a small amount of stannous octoate dropwise under the protection of Ar, continue vacuum drying for 30 minutes, add 2.5 g of D-lactide and 5 mL of ultra-dry toluene as solvent under the protection of Ar, and heat to reflux in an oil bath at 120 ° C for 12 h . After the reaction, drop the toluene solution of the product methoxypolyethylene glycol-polylactic acid into frozen anhydrous ether for reprecipitation, collect it into a 50mL centrifuge tube, and centrifuge at 10000rpm for 2min to remove the upper liquid and keep the bottom solid . Then it was dissolved in dichloromethane, reprecipitated in frozen anhydrous ether for the second time, centrifuged...

Embodiment 2

[0050] Take 1.000g CH 3 O-PEG 1000 -OH in a 50mL three-neck reaction flask. Dry under vacuum at 60°C for 2 hours. After cooling to room temperature, add a small amount of stannous octoate dropwise under the protection of Ar, continue vacuum drying for 30 min, add 5 g of D-lactide and 7.5 mL of ultra-dry toluene as solvent under the protection of Ar, and heat to reflux in an oil bath at 120 °C for 12 h . After the reaction, drop the toluene solution of the product methoxypolyethylene glycol-polylactic acid into frozen anhydrous ether for reprecipitation, collect it into a 50mL centrifuge tube, and centrifuge at 10000rpm for 2min to remove the upper liquid and keep the bottom solid . Then it was dissolved in dichloromethane, reprecipitated in anhydrous ether for the second time, centrifuged and vacuum-dried to obtain the final sample.

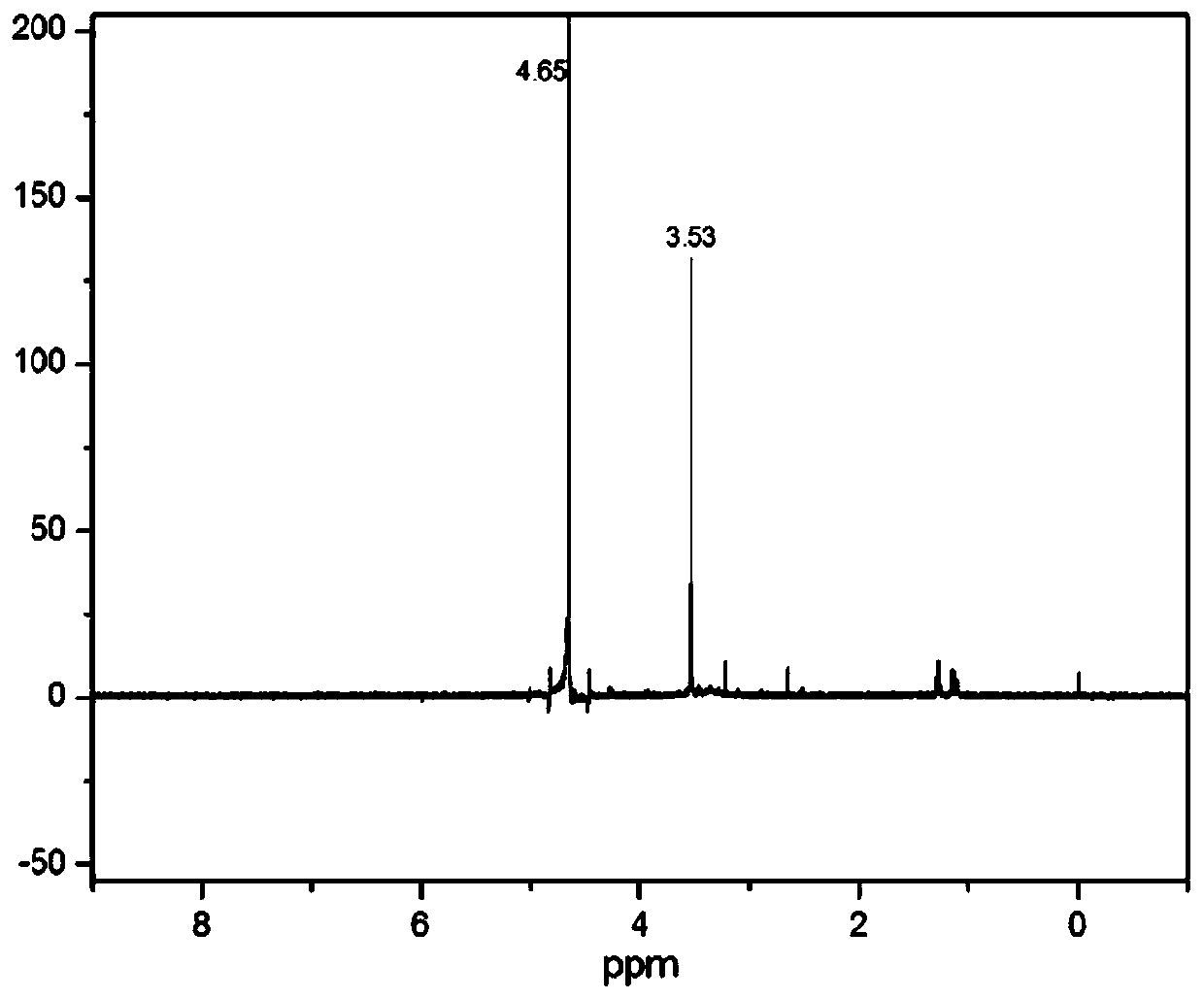

[0051] Dissolve methoxypolyethylene glycol-polylactic acid in tetrahydrofuran to obtain a polymer solution with a concentration of 50 mg / mL...

Embodiment 3

[0054] Take 1.000g CH 3 O-PEG 1000 -OH in a 50mL three-neck reaction flask. Dry under vacuum at 60°C for 2 hours. After cooling to room temperature, add a small amount of stannous octoate dropwise under the protection of Ar, continue vacuum drying for 30 minutes, add 2.5 g of D-lactide and 5 mL of ultra-dry toluene as solvent under the protection of Ar, and heat to reflux in an oil bath at 120 ° C for 12 h . After the reaction, drop the toluene solution of the product methoxypolyethylene glycol-polylactic acid into frozen anhydrous ether for reprecipitation, collect it into a 50mL centrifuge tube, and centrifuge at 10000rpm for 2min to remove the upper liquid and keep the bottom solid . Then it was dissolved in dichloromethane, reprecipitated in anhydrous ether for the second time, centrifuged and vacuum-dried to obtain the final sample.

[0055] Dissolve methoxypolyethylene glycol-polylactic acid in tetrahydrofuran to obtain a polymer solution with a concentration of 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com