Thread-trimming device of sewing machine

A sewing machine and bobbin thread technology, which is applied to the thread cutting mechanism, sewing machine components, sewing equipment, etc. in the sewing machine, can solve the problems of bobbin thread clamping spring fatigue elastic quality, seam off-thread, instability, etc., and achieve market availability Strong, simple adjustment method, good thread trimming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

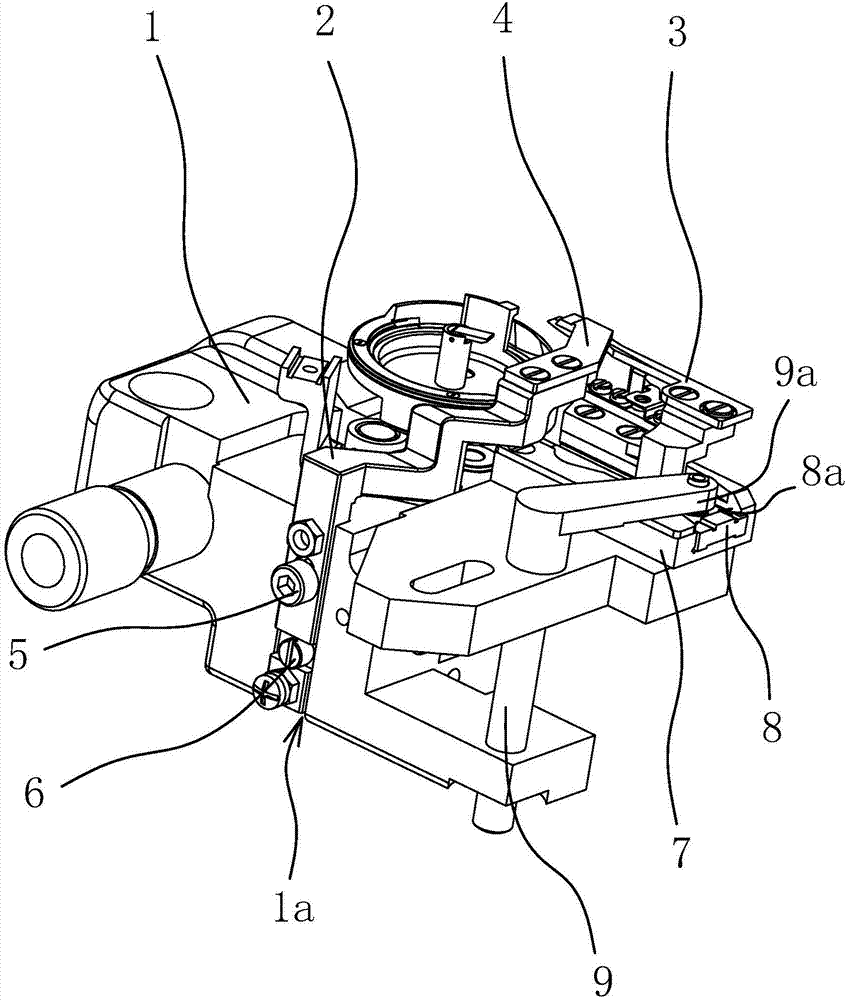

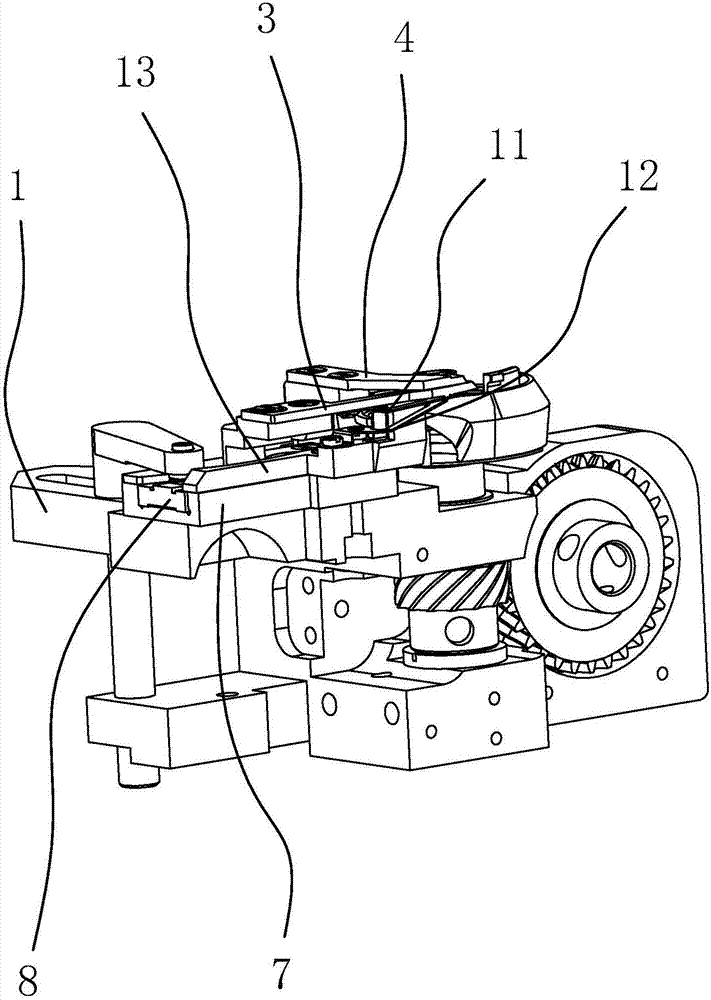

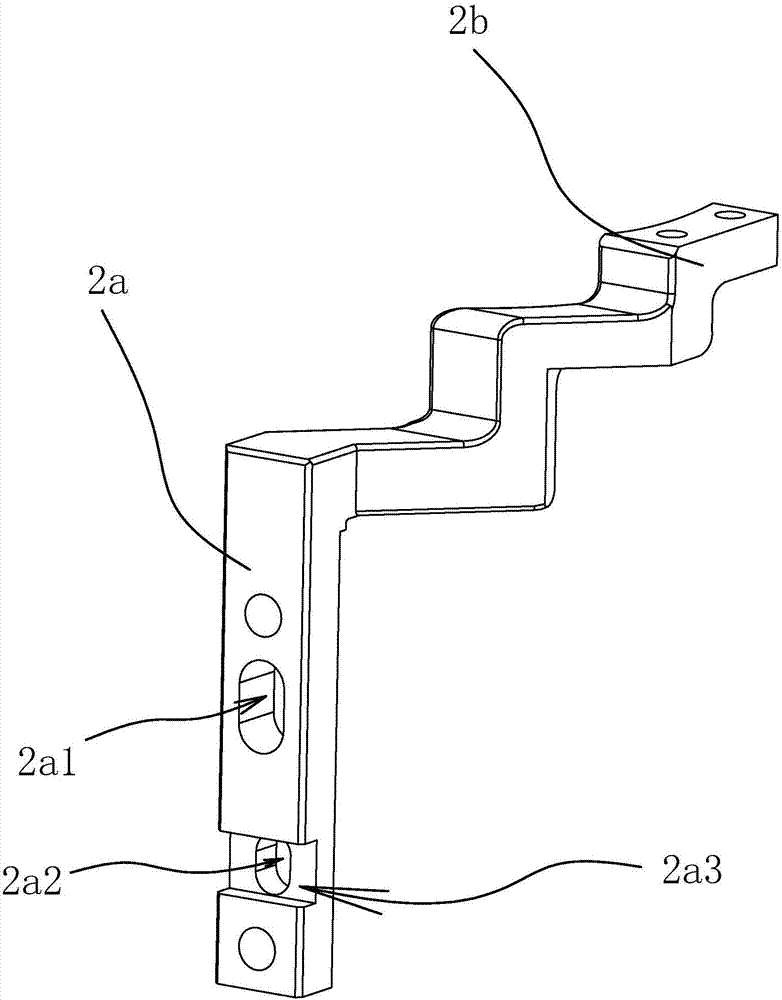

[0032] Such as figure 1 with 2 As shown, the sewing machine includes a rotary shuttle table 1. The thread trimming device includes a fixed knife holder 2, a movable knife 3, a fixed knife 4 and a needle plate.

[0033] Such as figure 2 with 7 As shown, a movable knife guide 7 is also fixed on the rotary hook table 1, and a guide chute is provided on the movable knife guide 7, and a movable knife drive slider 8 is slidably connected to the guide chute, and the movable knife 3 is fixed on the movable knife. On the driving slider 8, the rotary shuttle table 1 is also rotatably connected with a movable knife rotating shaft 9, one end of the movable knife rotating shaft 9 has a swing rod 9a, the movable knife driving slider 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com