Wellhead pressure testing and seal examining device

A sealing and pressure testing technology, applied in construction and other fields, can solve problems such as reliable sealing, inability to guarantee blowout preventers, personal casualties, etc., achieve reliable work, avoid personal casualties and property losses, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

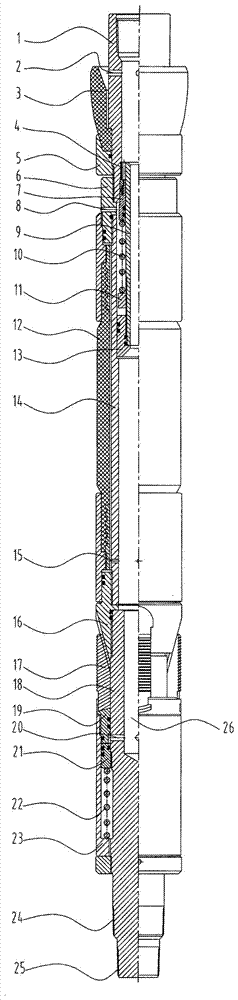

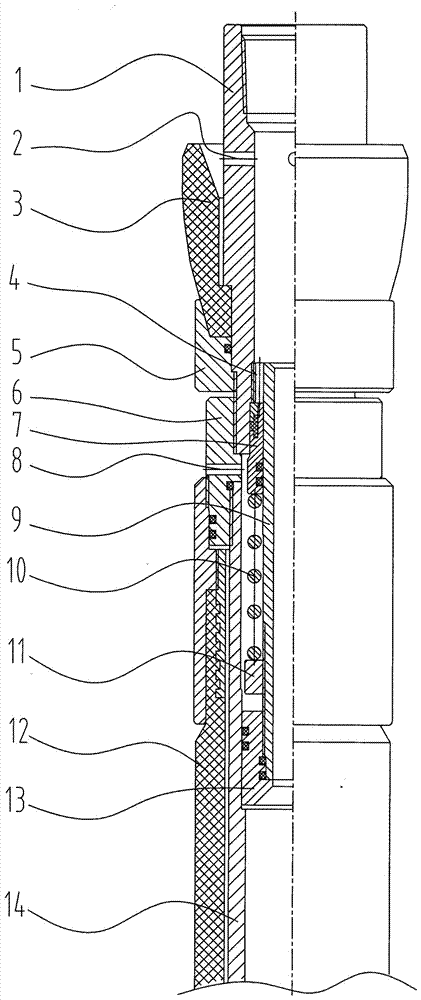

[0009] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0010] It can be seen from the figure that the embodiment of the present invention includes a cup shaft 1, a cup 3, a cup cap 5, a connecting joint 6, a piston 7, a sealing shaft 9, a spring 10, a pressure regulating seat 11, a rubber cylinder 12, and a sealing sleeve 13. Inner tube 14, cone 16, slips 17, lower joint 18, slip holder 19, sealing plug 21, return spring 22, spring seat 23, upper pressure hole 2 on the cup shaft 1, cup 3 Set on the cup shaft 1, the inner shoulder of the cup 3 is pressed on the outer shoulder of the cup shaft 1, so that the cup 3 cannot move upward on the cup shaft 1, and the upper pressure hole 2 is in the Above the cup 3, the bell mouth of the cup 3 faces upwards, and the cup pressing cap 5 is connected to the cup shaft 1, and the cup pressing cap 5 buckles the cup 3 so that the cup 3 cannot move upwards on the cup shaft 1. Moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com