Extra-thick solid potassic salt mine mining method achieving one-time overall width mining

A mining method and technology of potash mines, which are applied in the mining field of ultra-thick solid potash mines with full thickness at one time, can solve the problems of low output and low mining efficiency, and achieve improved recovery rate, improved mining efficiency, and compact equipment layout continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

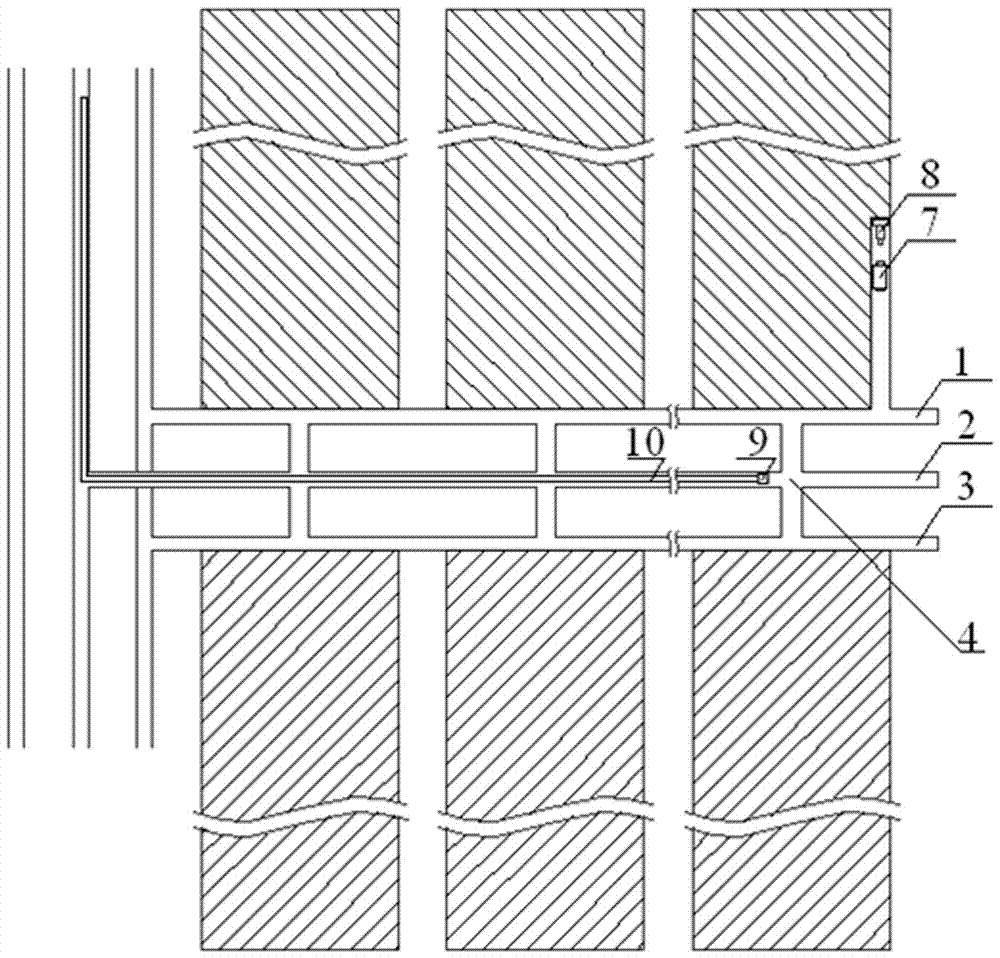

[0034] Mining equipment includes: Potassium mining machine, crawler type feeding crusher, shuttle car 7, belt conveyor 10, raise drilling rig;

[0035] A method for mining full-thick extra-thick solid potash mines at one time, comprising the steps of:

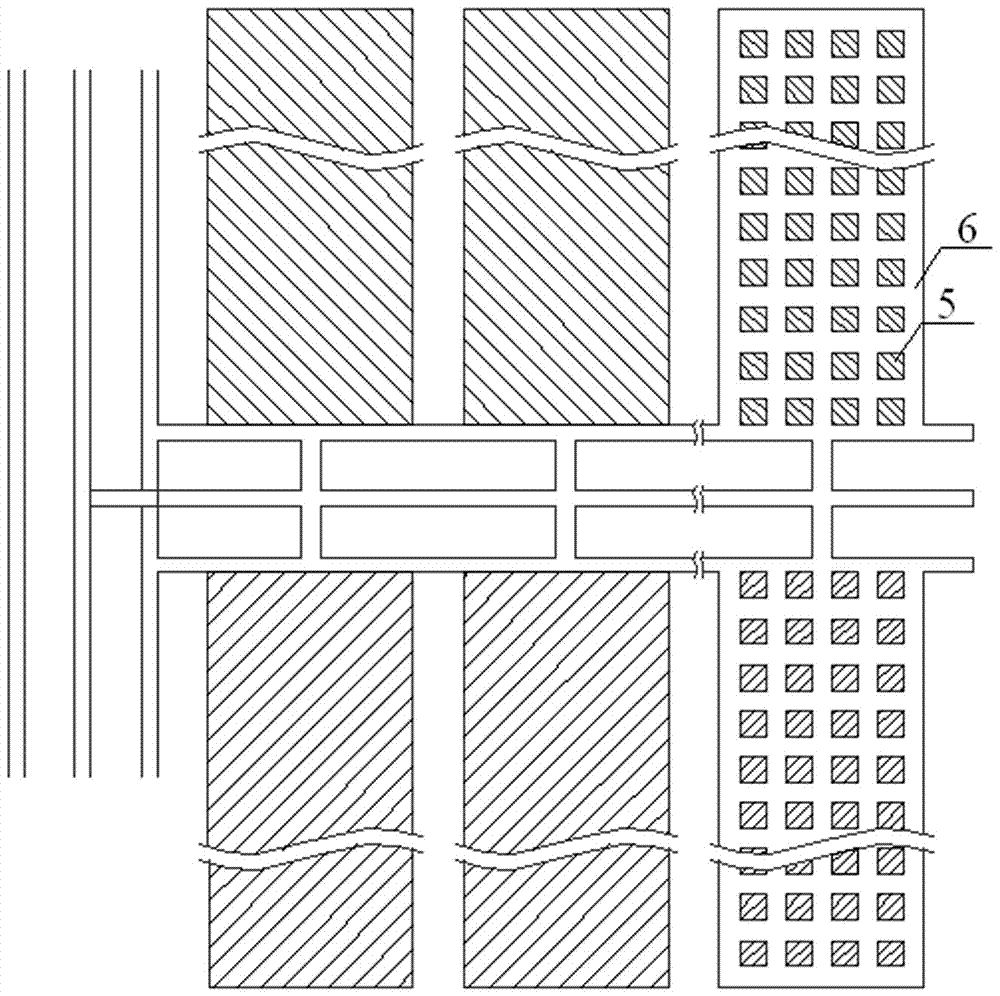

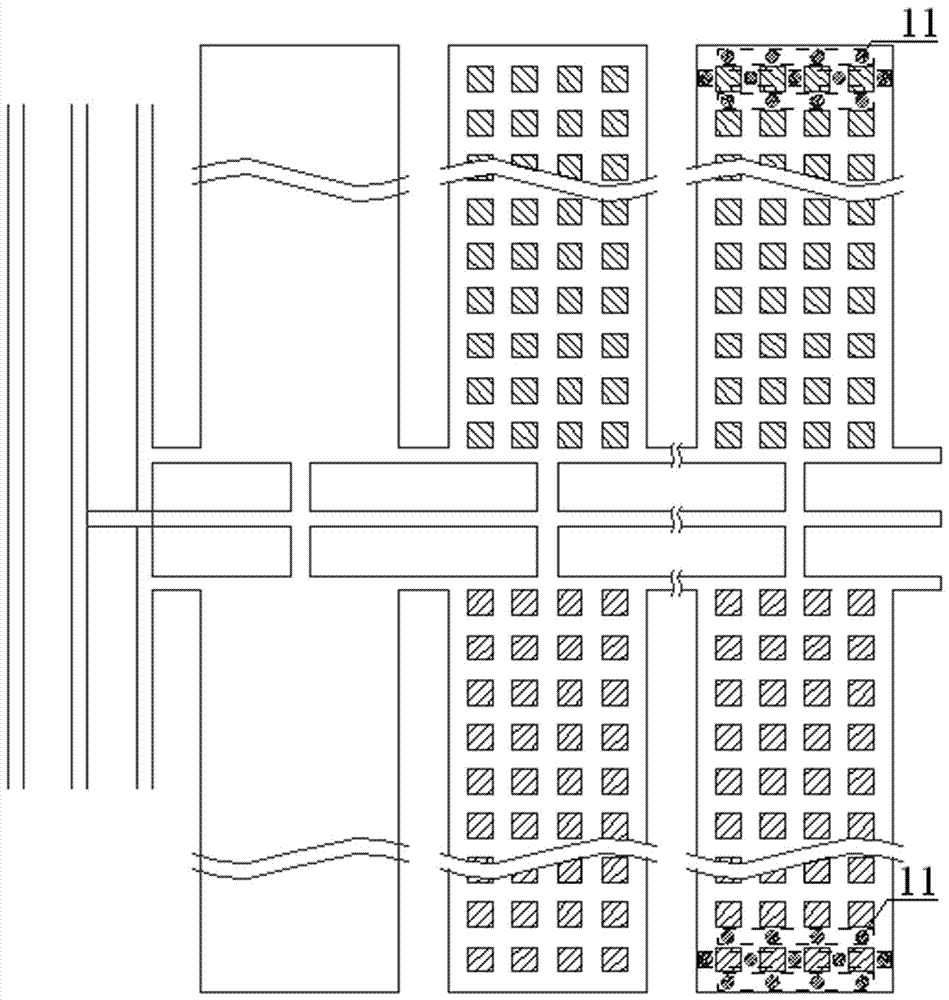

[0036] The first step is to design the mining area, arrange a main transportation lane 2 and two auxiliary transportation lanes in the mine layer of the mining area, and excavate a number of mining houses 6 vertically at the top and bottom of the mine seam on both sides of the main and auxiliary transportation roadways. Connect with connecting lanes 4 to form rectangular ore pillars 5, 5 to 6 mine houses 6 form a panel area, and leave 20m panel area ore pillars between adjacent panels;

[0037] The second step is equipment matching. The top working face and the bottom working face of the ore seam are equipped with a complete set of potash mining equipment for ore removal and transportation. The equipment mainly includes: potash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com