Self-help feeder for poultry

A technology for feeders and poultry, applied in applications, poultry industry, animal repellent, etc., can solve the problems of increasing manual workload, bringing germs to chickens, increasing feeding costs, etc., to reduce feeding costs, The effect of simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

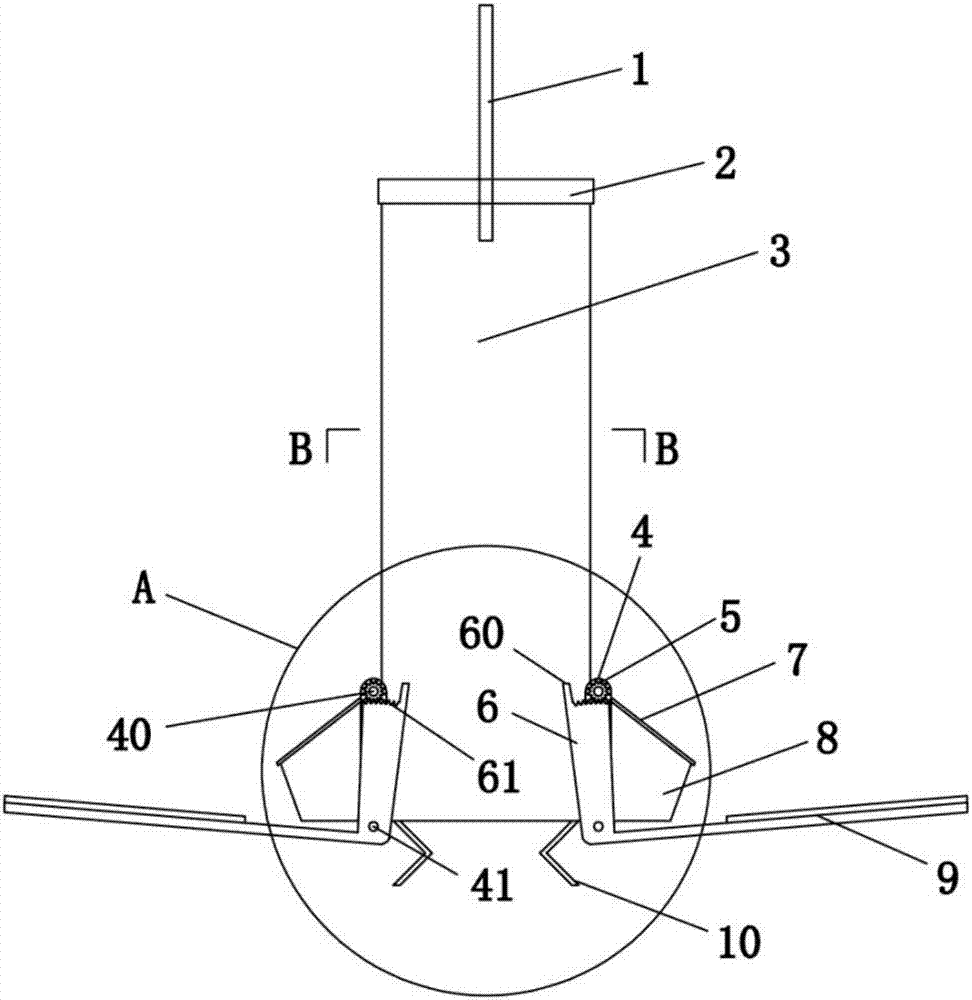

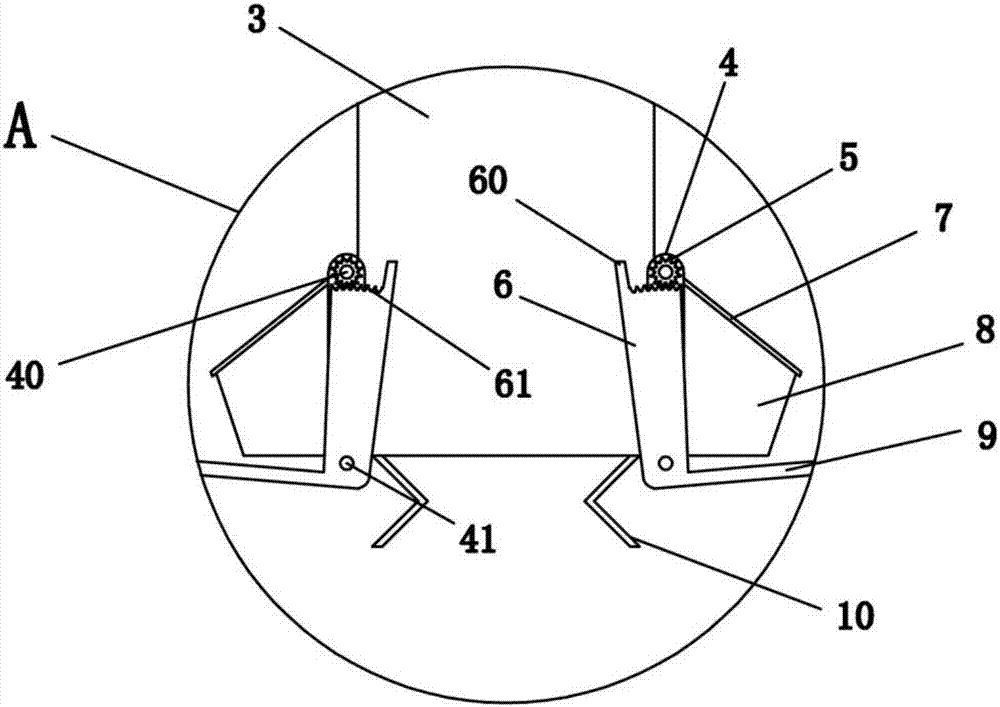

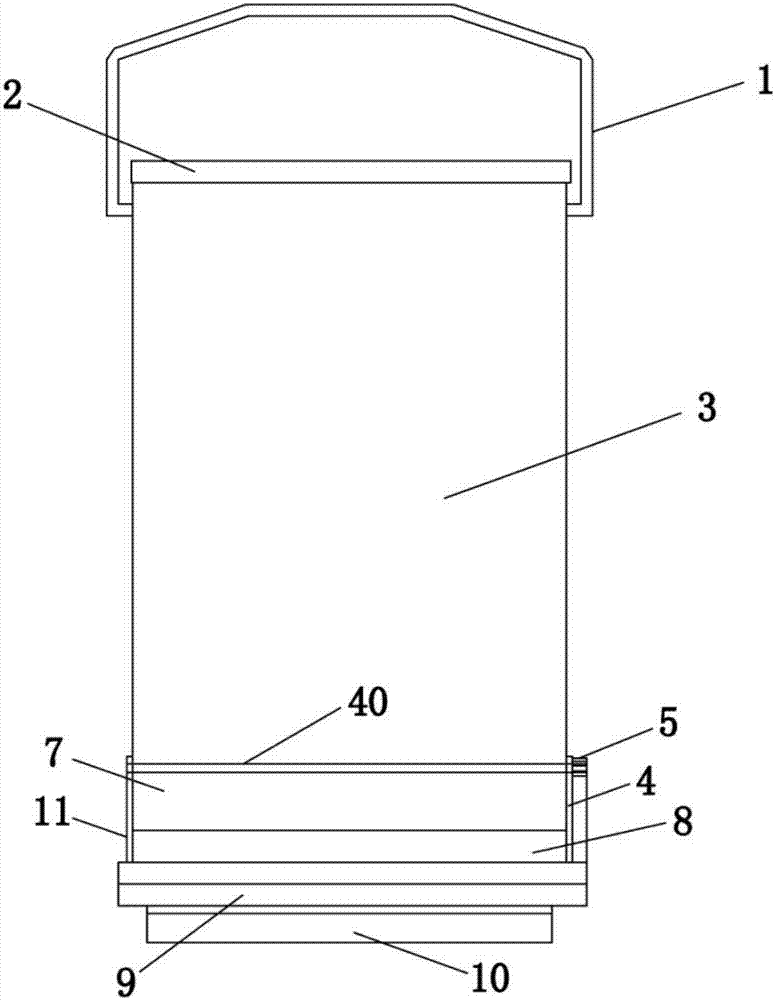

[0022] The technical solution of the present invention will be described below with reference to the drawings and embodiments.

[0023] Such as Figure 1 to Figure 5 As shown, the self-service feeder for poultry according to the present invention includes a feed bucket 3, and two sides of the bottom of the feed bucket 3 are provided with feeding troughs 8 respectively. The feed trough 8 is connected with the feed bucket 3, and the feed trough 8 Correspondingly, a rat-proof door 7 is provided, and the rat-proof door 7 closes the feeding trough 8 through a self-service rat-proof door closing mechanism. The above constitutes the basic structure of the present invention.

[0024] The present invention adopts such a structural arrangement. By providing a rat-proof door 7 on the feeding trough 8, the rat-proof door 7 is driven by a self-service rat-proof door closing mechanism, thereby closing the feeding trough 8 and effectively To prevent the stealing of feed by various non-artificia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com