Variable rigidity service robot joint

A service robot and variable stiffness technology, applied in the field of service robots, can solve the problems of large-range movement of flexible joints, small shrinkage rate of shape memory alloy wire, large driver design, etc., to achieve high output power, simple drive mode, and small size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

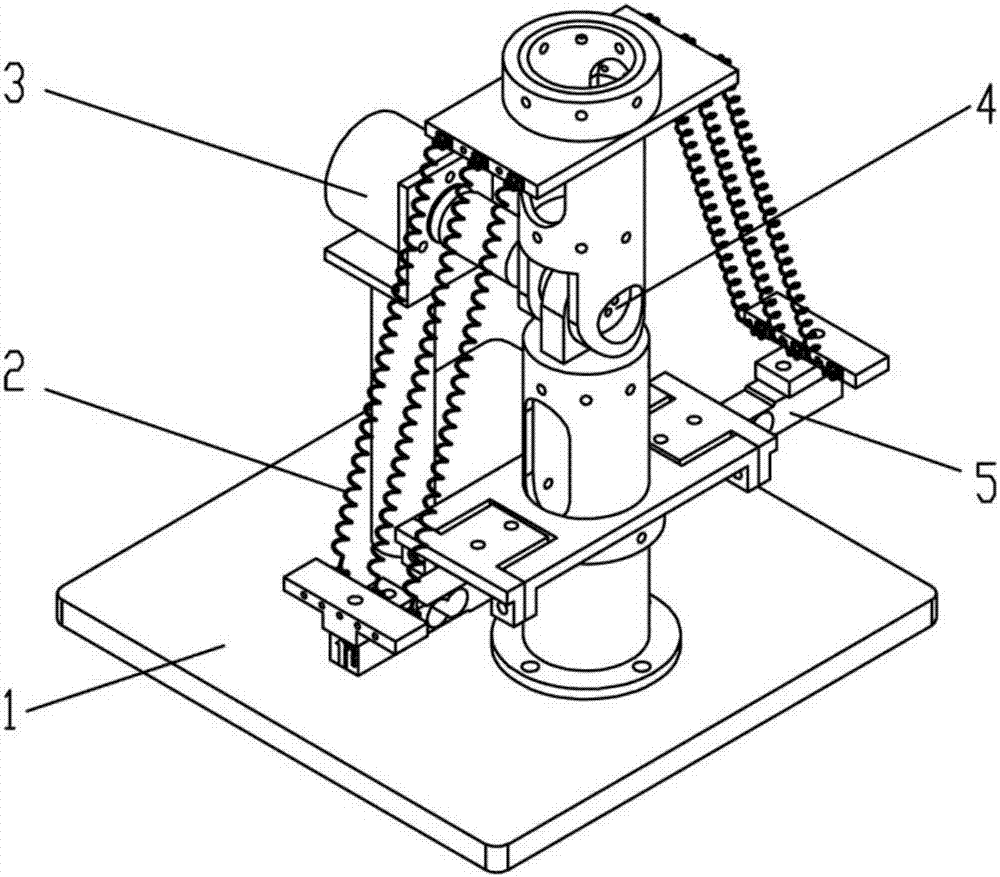

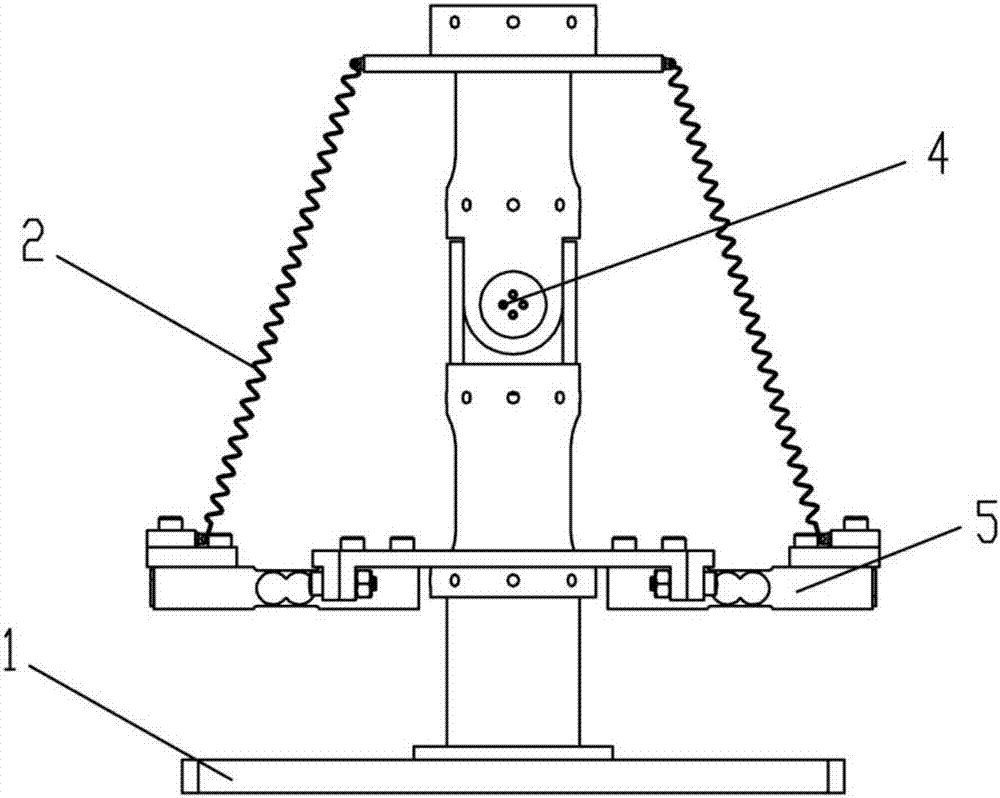

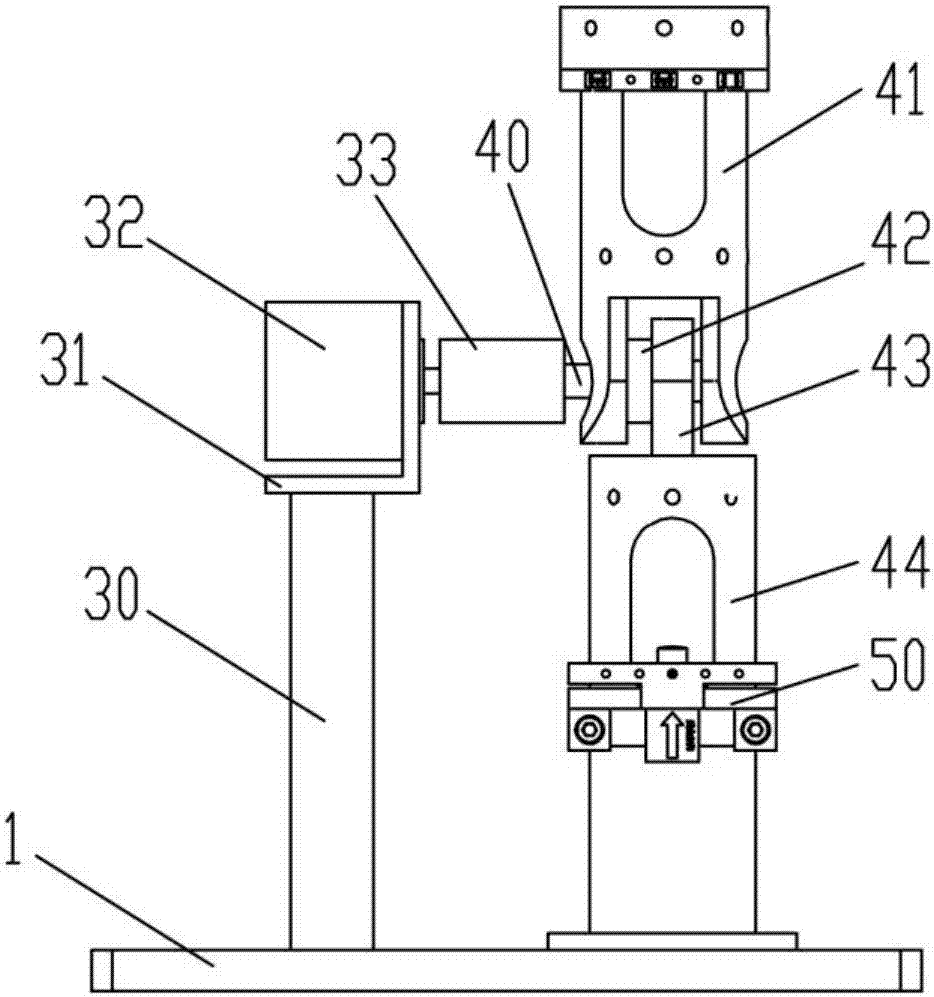

[0023] Such as figure 1 with Figure 5 As shown, a variable stiffness service robot joint according to the present invention includes a base 1, a drive unit 2, a position information collection unit 3, a rotary joint unit 4 and a driving force collection unit 5, a position information collection unit 3 and a rotary joint unit The upper ends of 4 are coaxially connected, the lower ends of the position information collection unit 3 and the rotary joint unit 4 are respectively fixed on the base 1, the driving force collection unit 5 is fixed on the rotary joint unit 4, and one end of the driving unit 2 is connected to the rotary joint unit 4, The other end is connected to the driving force acquisition unit 5. The driving unit 2 includes a shape memory alloy spring 20, an adjustable digital power supply, a voltage control module and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com