Electrostatic thawing refrigerator

An electrostatic and refrigerator technology, applied in the field of defrosting refrigerators, can solve problems such as poor airflow circulation, discounted cooling and heating effects, and achieve the effects of avoiding temperature regulation, reducing thawing time difference, and overcoming large wind resistance area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

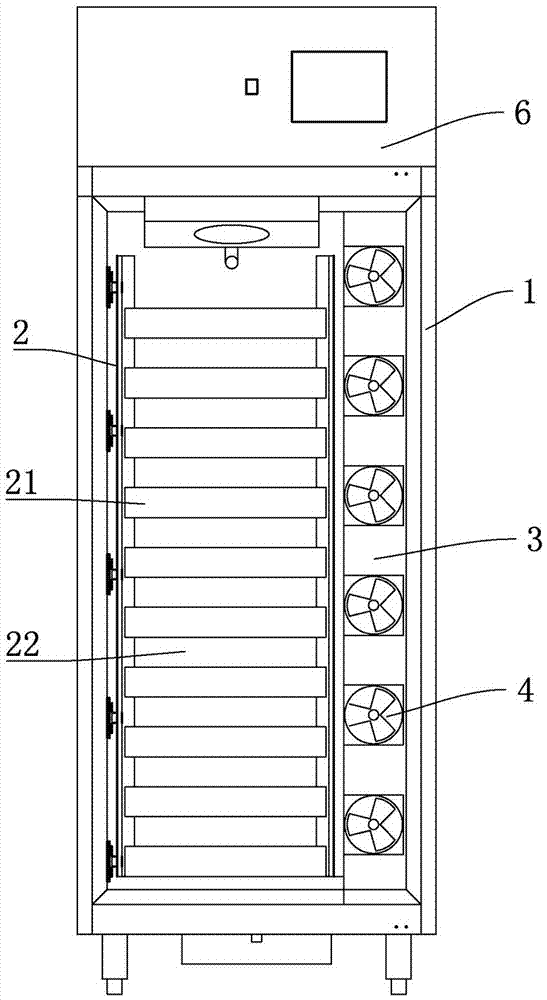

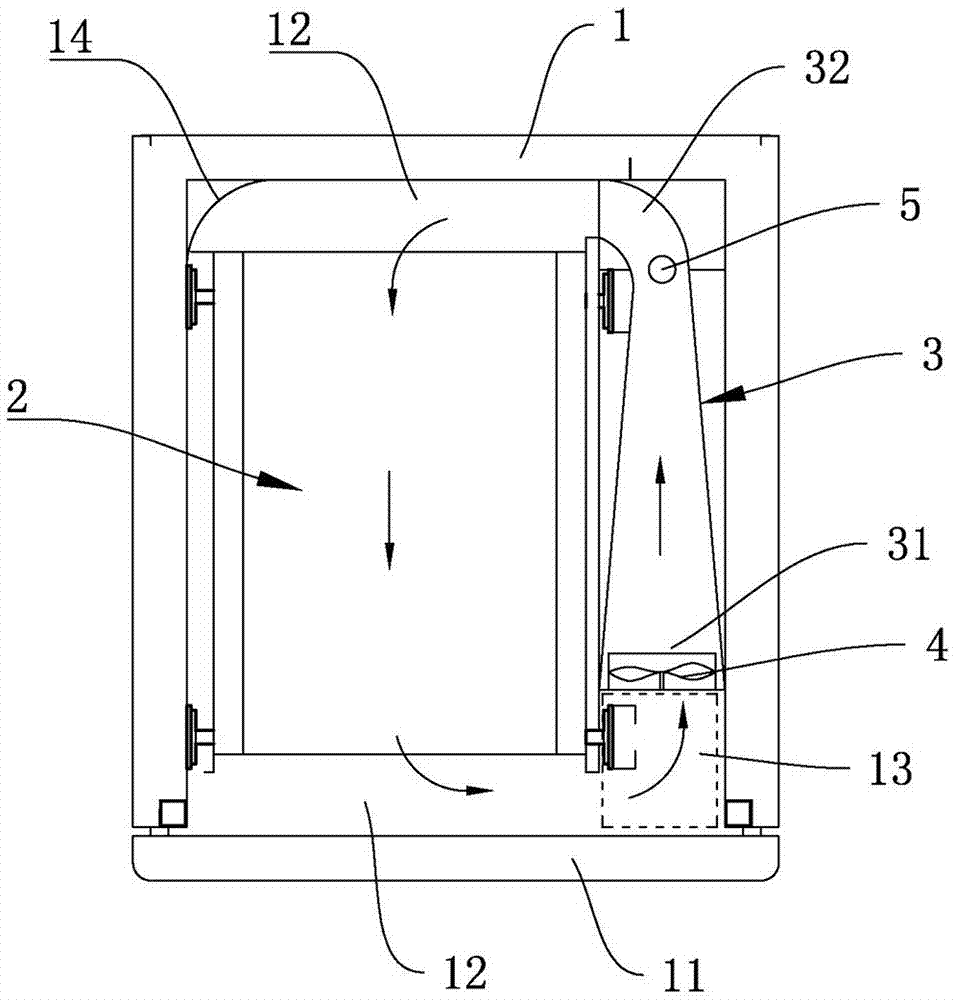

[0020] Embodiment 1: as figure 1 and figure 2 As shown, an electrostatic thawing refrigerator includes a box body 1, a thawing shelf 2 arranged in the box body 1, an electrostatic induction device capable of generating a high-voltage electrostatic field, and a temperature control device 6 for cooling or heating the box body 1 . The front side of the box body 1 is provided with a box door 11, the left side of the thawing shelf 2 is fixed on the inner wall of the left side of the box body 1 through an insulating seat, and the right side of the thawing shelf 2 is fixed on the left and right sides of the box body 1 through an insulating seat on the fixed bracket. The thawing rack 2 includes several thawing trays 21 stacked up and down, and the quantity is determined by the actual situation. The two vertically adjacent thawing trays 21 are arranged at intervals and a spacer 22 is formed between the vertically adjacent two thawing trays 21 , and the static induction device is co...

Embodiment 2

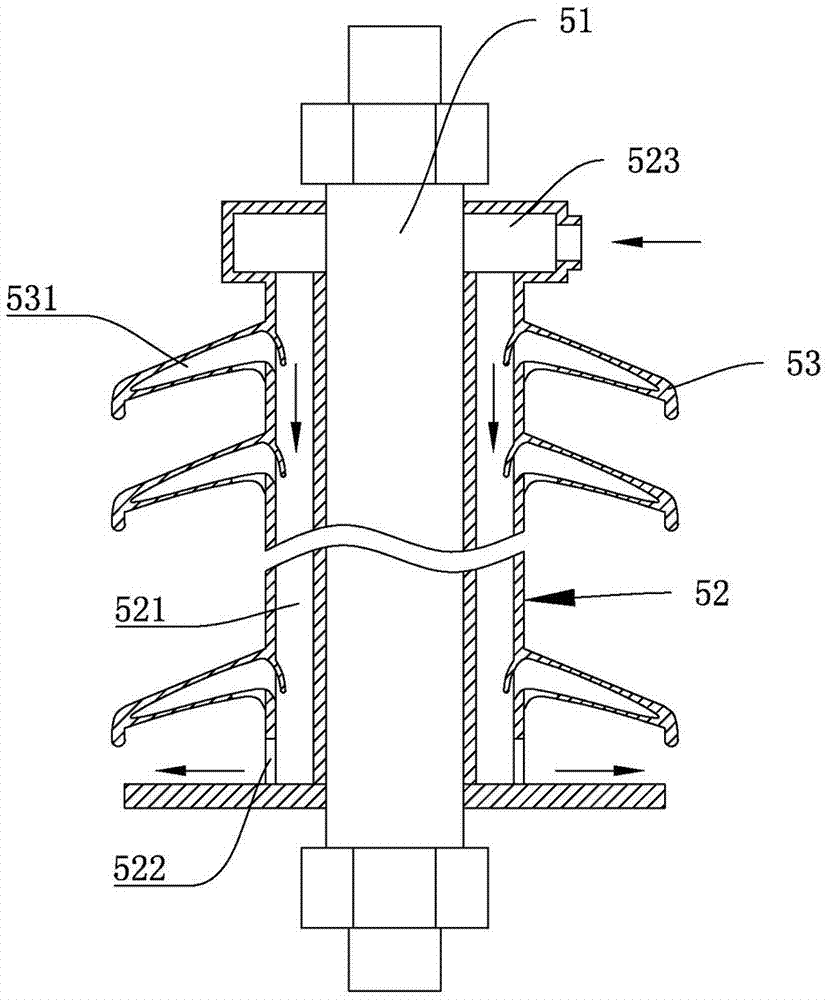

[0024] Embodiment 2: as image 3 and Figure 4 As shown, the difference from Embodiment 1 is that a heat dissipation sleeve 52 is provided on the outside of the heating rod 51, and the wall of the heat dissipation sleeve 52 is a hollow structure, and a flow channel 521 is provided inside, and an air inlet is provided at the upper end of the heat dissipation sleeve 52. The terminal 523 and the air intake terminal 523 blow air to the flow channel 521 through the blower, and the lower end of the cooling sleeve 52 is provided with a lower opening. The outer side of the heat dissipation sleeve 52 is provided with heat dissipation fins 53 spaced up and down, and the heat dissipation fins 53 are inclined downward from the root to the end. A cavity 531 is provided in the heat dissipation fin 53 , and a first opening 532 is provided at the joint between the lower surface of the heat dissipation fin 53 and the heat dissipation sleeve 52 , and the first opening 532 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com