DC (Directly compressible)-xylitol and preparation method thereof

A xylitol and wet granulation technology, which is used in pharmaceutical formulations, medical preparations with inactive ingredients, and pill delivery, etc., can solve the problems of unfitness, high friability, low tablet hardness, etc. quality, overcoming strong hygroscopicity, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

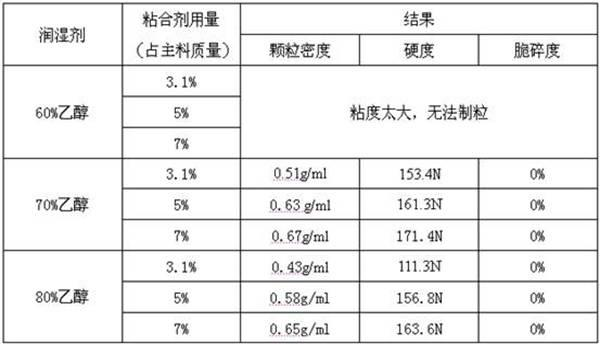

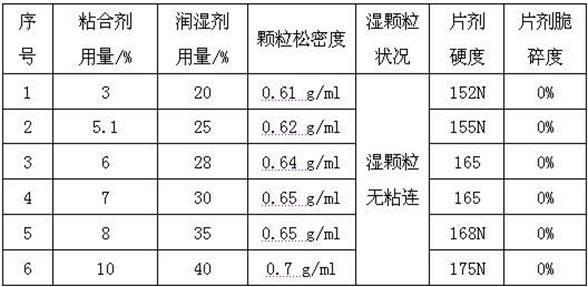

[0030] DC-xylitol of the present invention mainly comprises main material xylitol, binder carboxymethylcellulose sodium (CMC-Na) and wetting agent ethanol solution, and the concentration of described ethanol solution is 70% (w / w), wherein, the consumption of binding agent and wetting agent sees the following table, prepare DC-xylitol according to following preparation method, compress tablet and detect its hardness and friability:

[0031] 1. Raw material preparation: Grind and sieve the xylitol main material and the binder sodium carboxymethyl cellulose to 80 mesh respectively, and set aside;

[0032] 2. Wet granulation: Mix the treated raw materials and binders evenly in a wet granulator for about 3 minutes, then add 70% ethanol solution, stir at low speed for 5-10 minutes, then stir at high speed Cut for 5-10 minutes, then granulate twice with a 30-mesh sieve in a swing granulator, and dry at 45°C until the moisture content is less than 0.5% (w / w);

[0033] 3. Tablet pres...

Embodiment 2

[0036] 500g of xylitol, 16g of sodium carboxymethylcellulose, and 119.7g of 70% ethanol solution are made into granules and compressed according to the following methods:

[0037] 1. Raw material preparation: Grind and sieve the xylitol main material and the binder sodium carboxymethyl cellulose to 80 mesh respectively, and set aside;

[0038] 2. Wet granulation: Mix the treated raw materials and binder in a wet granulator for about 3 minutes, then add 70% ethanol solution, first stir at low speed for 5 minutes, then stir at high speed for 5 minutes, then Granulate twice with a 30-mesh sieve in a swing granulator, and dry at 45°C until the moisture content is less than 0.5% (w / w).

[0039] 3. Screening and tabletting: pass the dried particles through a 24-mesh sieve, and discard a small amount of products that fail to pass the 24-mesh sieve to obtain DC-xylitol with uniform thickness, and perform tabletting according to conventional operations to obtain xylose Alcohol Tablets...

Embodiment 3

[0042] 500g of xylitol, 20g of sodium carboxymethylcellulose, and 115g of 70% ethanol solution are made into granules and compressed according to the following methods:

[0043] 1. Raw material preparation: Grind and sieve the xylitol main material and the binder sodium carboxymethyl cellulose to 80 mesh respectively, and set aside;

[0044] 2. Wet granulation: Mix the treated raw materials and binders evenly in a wet granulator for about 3 minutes, then add 70% ethanol solution, first stir at low speed for 6 minutes, and then stir at high speed for 6 minutes. Then granulate twice with a 30-mesh sieve in a swing granulator, and dry at 45°C until the moisture content is less than 0.5% (w / w).

[0045] 3. Screening and tabletting: pass the dried particles through a 24-mesh sieve, and discard a small amount of products that fail to pass the 24-mesh sieve to obtain DC-xylitol with uniform thickness, and perform tabletting according to conventional operations to obtain xylose Alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| friability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com