High-strength low-temperature-resistant material for shoes and preparation method of high-strength low-temperature-resistant material

A high-strength, low-temperature-resistant technology, applied in the field of shoes, can solve the problems of poor cold resistance and low fluidity, and achieve the effects of low price, remarkable wear resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

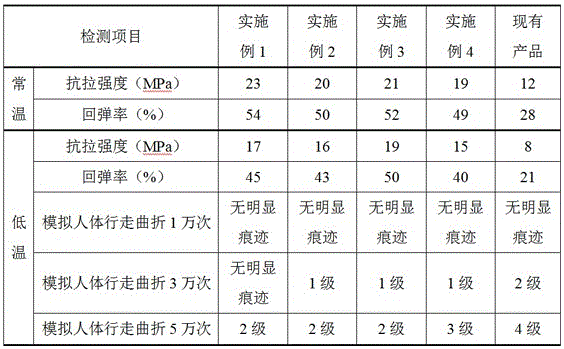

Examples

Embodiment 1

[0019] First put 50 parts by weight of nitrile rubber and 10 parts by weight of natural rubber into the mixing chamber, keep the temperature in the mixing chamber at 60°C, and keep the pressure at 0.2Mpa. After pressing down for 5 minutes with the pressing hammer, it will rise, and then put in 5 parts by weight of polyvinyl chloride powder and 1 part by weight of dioctyl phthalate, mixed evenly, and pressed down with a pressing hammer for 3 minutes to obtain a mixer; then mix the mixer with 1 part by weight of sulfur powder, 3 parts by weight of Zinc, 1 part by weight of dibenzothiazole disulfide and 1 part by weight of N-phenyl-1-naphthylamine were put into a banbury mixer and pressed together for 3.5 minutes, mixed evenly and then discharged after banburying at 80°C for 5 minutes; The mixed rubber is discharged into the designated mold for cooling and forming, and then cut and processed according to the requirements to obtain high-strength and low-temperature resistant materi...

Embodiment 2

[0021] First put 60 parts by weight of nitrile rubber and 60 parts by weight of natural rubber into the mixing chamber, keep the temperature in the mixing chamber at 70°C, and keep the pressure at 0.2Mpa. After pressing down for 5 minutes with the pressing hammer, it will rise, and then put in 10 parts by weight of polyvinyl chloride powder and 1.5 parts by weight of diisononyl phthalate, after mixing evenly, the pressing hammer was pressed down for 3 minutes to obtain the mixer; then mix the mixer with 2 parts by weight of sulfur powder, 5 parts by weight of Zinc carbonate, 3.5 parts by weight of tetramethylthiuram disulfide and 1.5 parts by weight of N-phenyl-N'-isopropyl-p-phenylenediamine were put into the internal mixer and pressed for 2 minutes, and mixed uniformly at 90°C After banburying for 4 minutes, the material is discharged; the mixed rubber is discharged into the designated mold for cooling and forming, and then cut and processed according to the requirements to o...

Embodiment 3

[0023] First put 70 parts by weight of nitrile rubber and 30 parts by weight of natural rubber into the mixing chamber, keep the temperature in the mixing chamber at 90°C, and keep the pressure at 0.2Mpa. After pressing down for 5 minutes with the pressing hammer, it will rise, and then put in 13 parts by weight of polyvinyl chloride powder and 2 parts by weight of dioctyl phthalate, after mixing evenly, the pressing hammer was pressed down for 3 minutes to obtain the mixer; then mix the mixer with 1.8 parts by weight of sulfur powder, 4.5 parts by weight of carbonic acid Calcium, 4 parts by weight of dibenzothiazole disulfide and 2 parts by weight of 2-mercaptobenzimidazole were put into a banbury mixer and pressed for 5 minutes, mixed evenly and then banburyed for 4.5 minutes at 100°C before discharging; the mixed rubber was discharged Put it into the designated mold for cooling and forming, and then cut and process according to the requirements to obtain high-strength and lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com