A multi-material wire connector

A multi-material and catheter technology, applied in the direction of conductive connection, connection, welding/welding connection, etc., can solve the problems of poor contact at connection points, broken wires, time-consuming and labor-intensive problems, and achieve high curing efficiency, accelerated curing, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

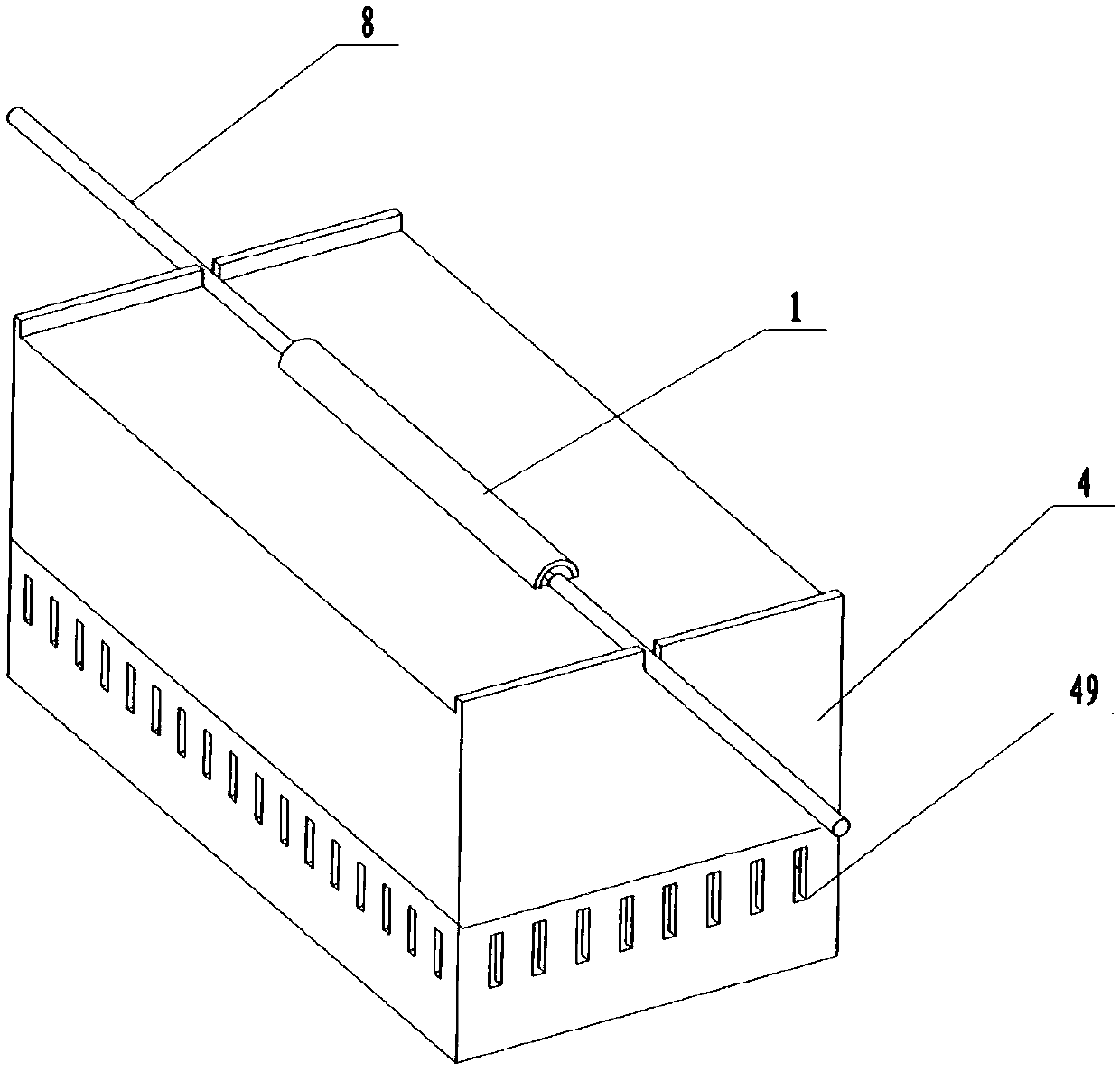

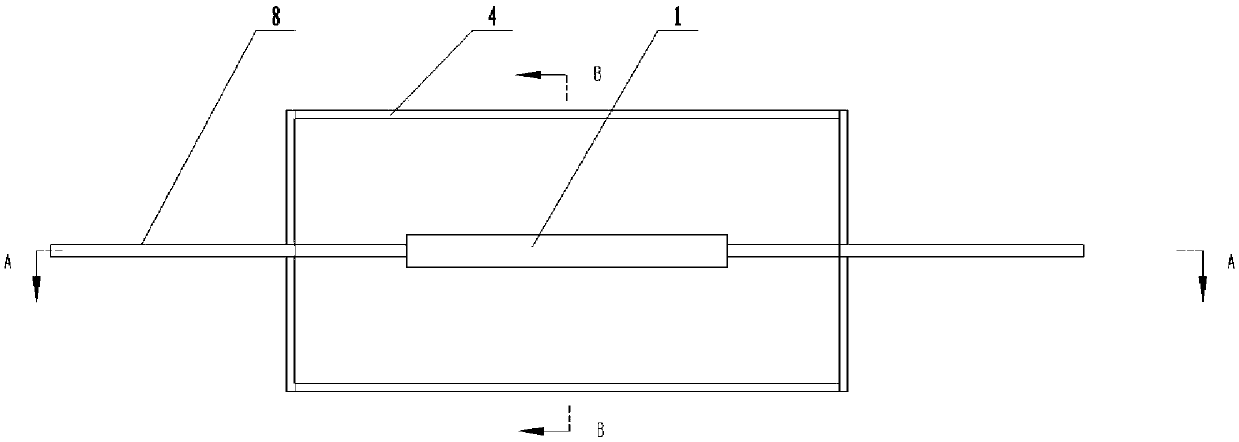

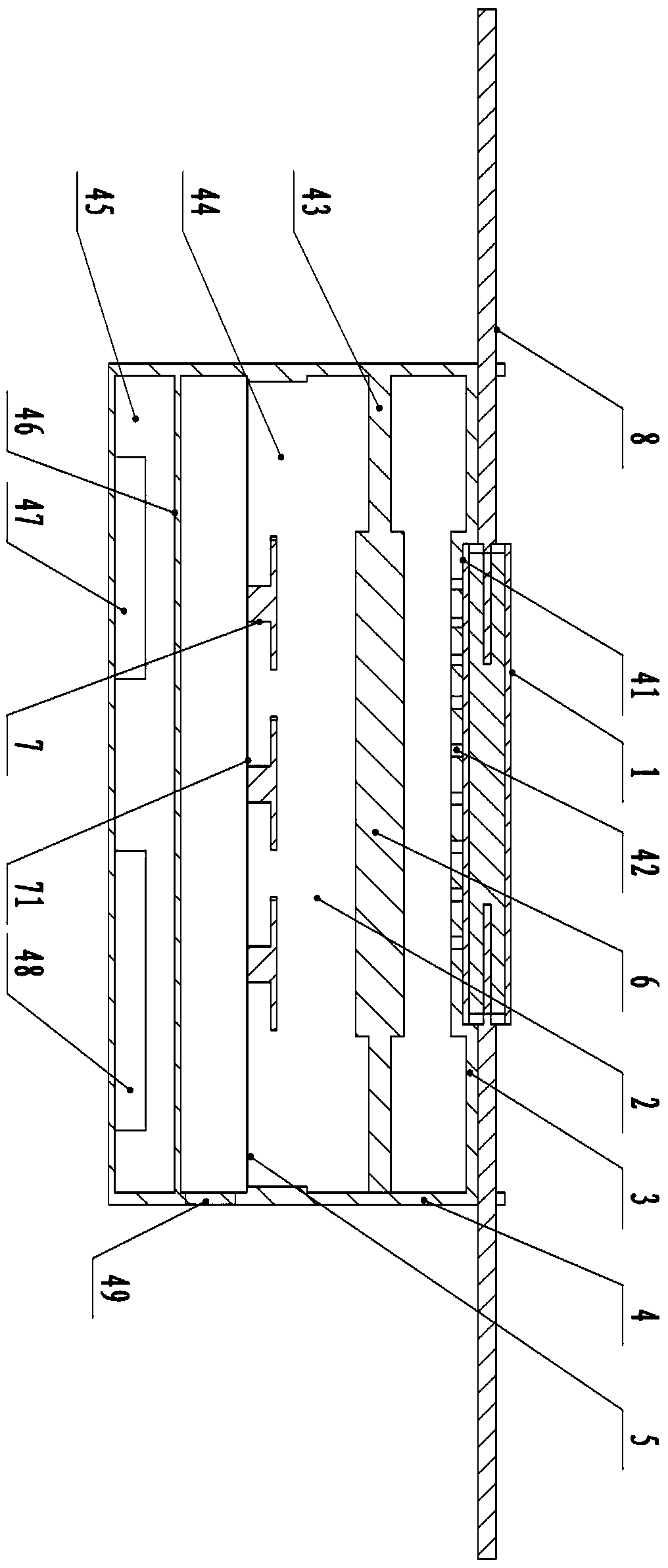

[0031] Figure 1 to Figure 6 It is an embodiment of the present invention, a multi-material wire connection instrument, including a catheter 1, a heating device 2 and a fixing device 3, the fixing device 3 includes a fixing frame 4, a heating device fixing frame 5, and the fixing device The frame 4 is provided with a groove 41 for defining the conduit, the heating device 2 is arranged on the heating device fixing frame 5, the heating device fixing frame 5 is arranged on the fixing frame 4, and the heating device 2 includes a heating tube 6 And blowing device 7, described blowing device 7 is fixed on the heating device fixed frame 5, and described conduit 1 is located in groove 41, and the size of groove 41 cooperates with the size of conduit 1, is difficult to produce rocking, and descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com