Fuel pump

A technology for fuel pumps and pump chambers, which is applied to pumps, liquid fuel feeders, liquid fuel engines, etc., and can solve problems such as pump efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

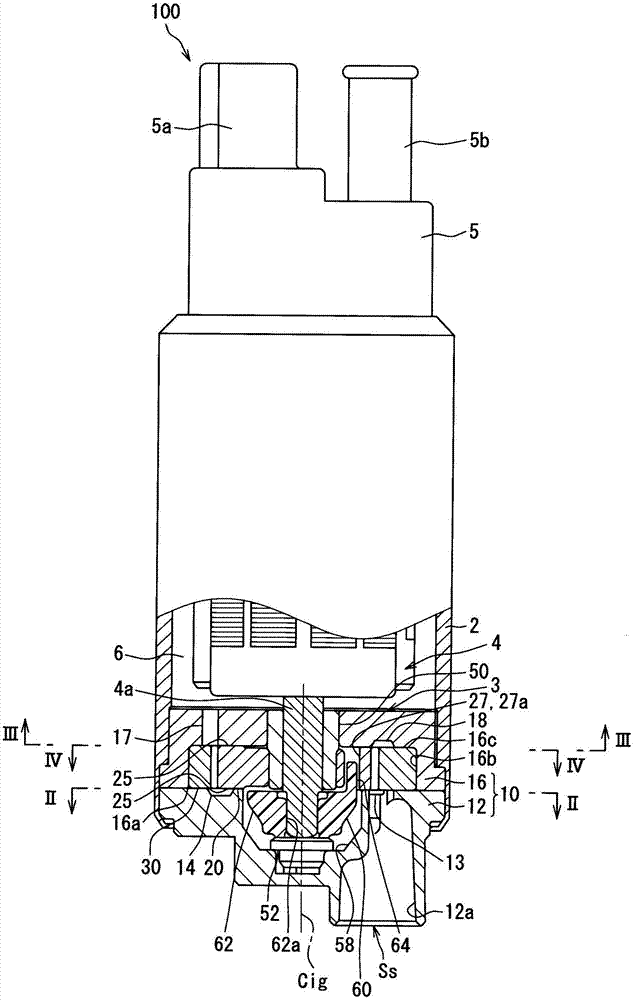

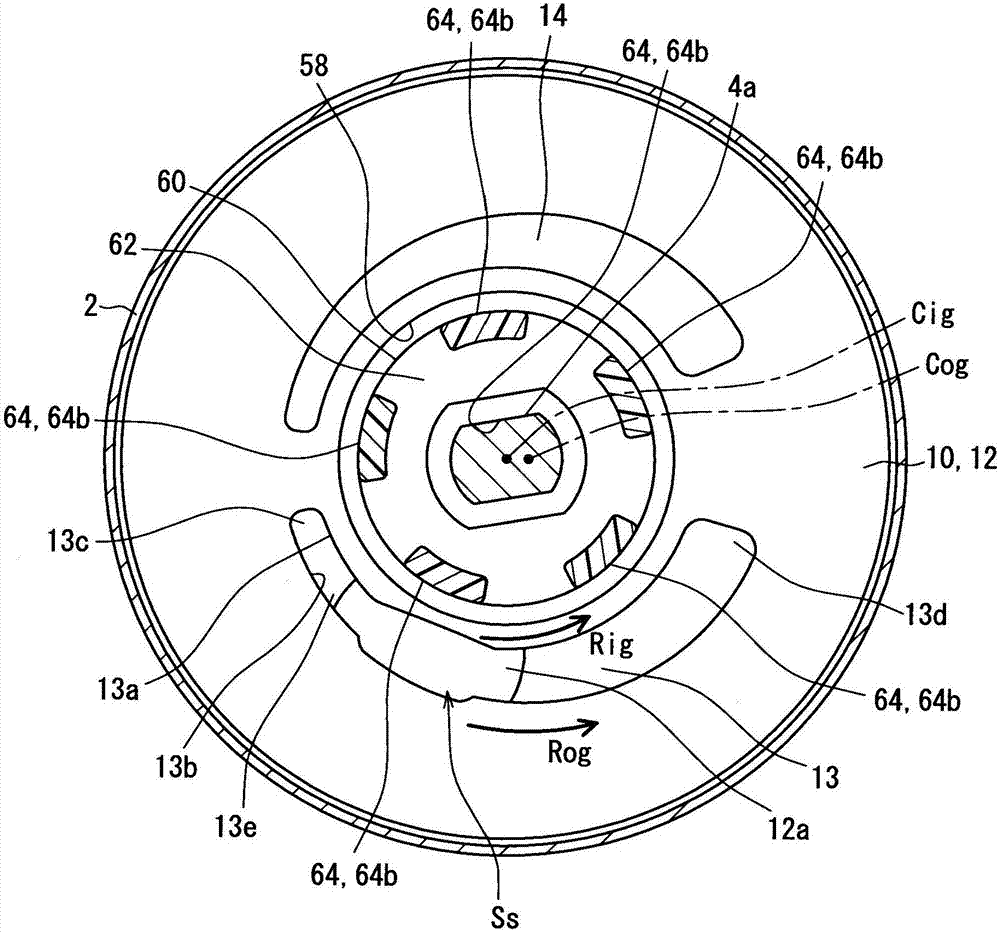

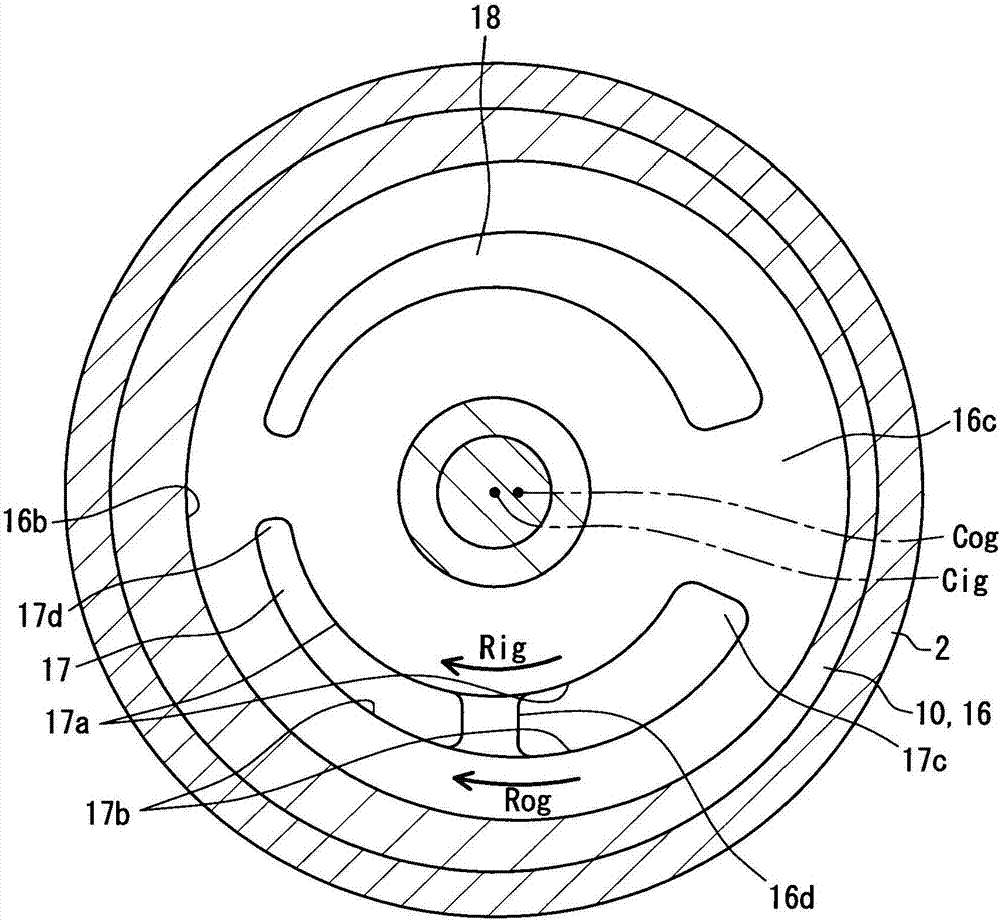

[0040] Hereinafter, the first embodiment will be described based on the drawings.

[0041] Such as figure 1 As shown, the fuel pump 100 of the first embodiment is a positive displacement trochoid pump mounted on a vehicle. The fuel pump 100 includes a side cover 5 protruding to the outside from an end opposite to the pump body 3 so as to sandwich the pump body 3 and the electric motor 4 housed inside the cylindrical pump body 2 in the axial direction. Here, the side cover 5 includes an electrical connector 5 a for supplying electricity to the electric motor 4 and a discharge port 5 b for discharging fuel. In such a fuel pump 100 , the rotation shaft 4 a of the electric motor 4 is rotationally driven by energization from an external circuit via the electrical connector 5 a. As a result, the fuel sucked and pressurized by the pump main body 3 by the rotational force of the rotary shaft 4 a of the electric motor 4 is discharged from the discharge port 5 b. In addition, the fu...

no. 2 Embodiment approach

[0092] Hereinafter, a second embodiment will be described based on the drawings.

[0093] Such as Figure 13 As shown, the fuel pump 101 of the second embodiment is a positive displacement trochoid pump mounted on a vehicle. The fuel pump 101 includes a side cover 105 protruding to the outside from an end opposite to the pump body 103 , sandwiching a pump body 103 and an electric motor 104 accommodated in a cylindrical pump body 102 in the axial direction. Here, the side cover 105 includes an electrical connector 105 a for supplying electricity to the electric motor 104 and a discharge port 105 b for discharging fuel. In such a fuel pump 101 , the rotary shaft 104 a of the electric motor 104 is rotationally driven by energization from an external circuit through the electrical connector 105 a. As a result, the fuel sucked and pressurized by the rotation of the external gear 130 and the internal gear 120 of the pump main body 103 is discharged from the discharge port 105b by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com