Process pump having a crank drive

A process pump and crank mechanism technology, which is applied to the parts, pumps, and crankshafts of pumping devices used for elastic fluids, can solve problems such as increased fatigue failure, and achieve the effects of reduced vibration and uniform pumping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

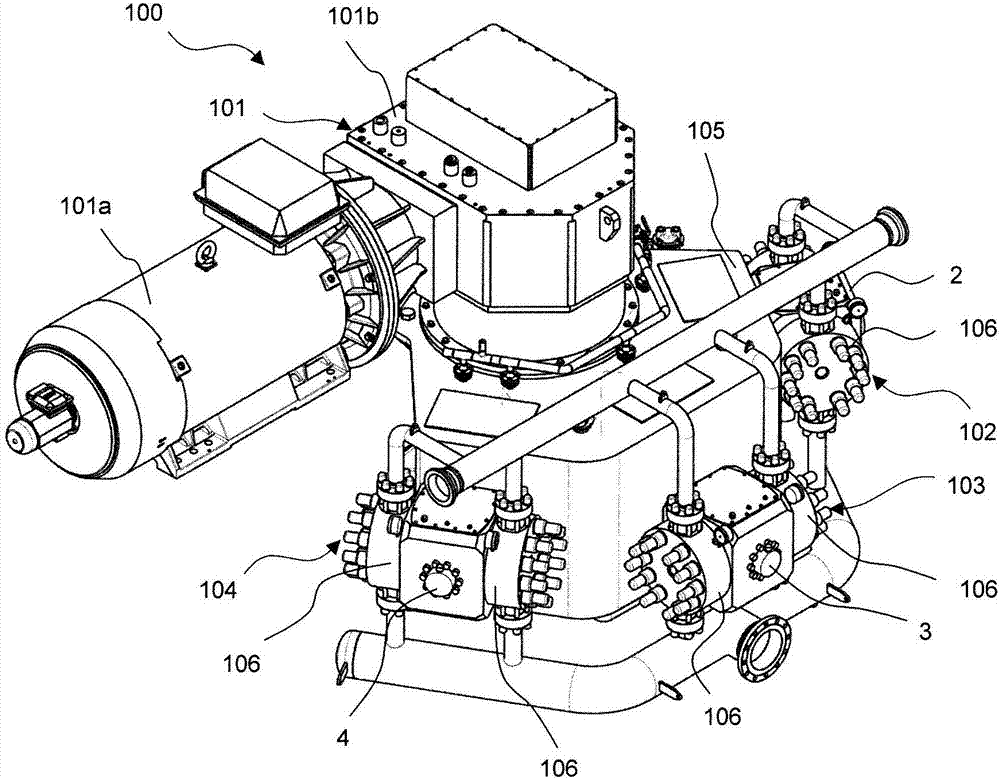

[0034] figure 1 A process pump 100 according to the invention is shown in . Process pump 100 has three barrels 2, 3, 4, respectively denoted as first barrel 2 ( figure 1 The most rear barrel), the second barrel 3 ( figure 1 middle barrel) and the third barrel 4 ( figure 1 in the front barrel). In the following, components labeled "first", "second", "third" or similar prefixes mean corresponding to the corresponding barrel 2, 3, 4.

[0035] In addition, if figure 1 As shown, the process pump 100 has double-acting pump heads 102, 103, 104 in addition to barrels 2, 3, 4, each double-acting pump head has two pump covers 106, and the piping leading to the suction or delivery line is covered. Mounts to pump cover. Furthermore, the process pump 100 has a drive device 101 (for example, an electric motor 101 a and a speed reducer 101 b ) and a housing 105 .

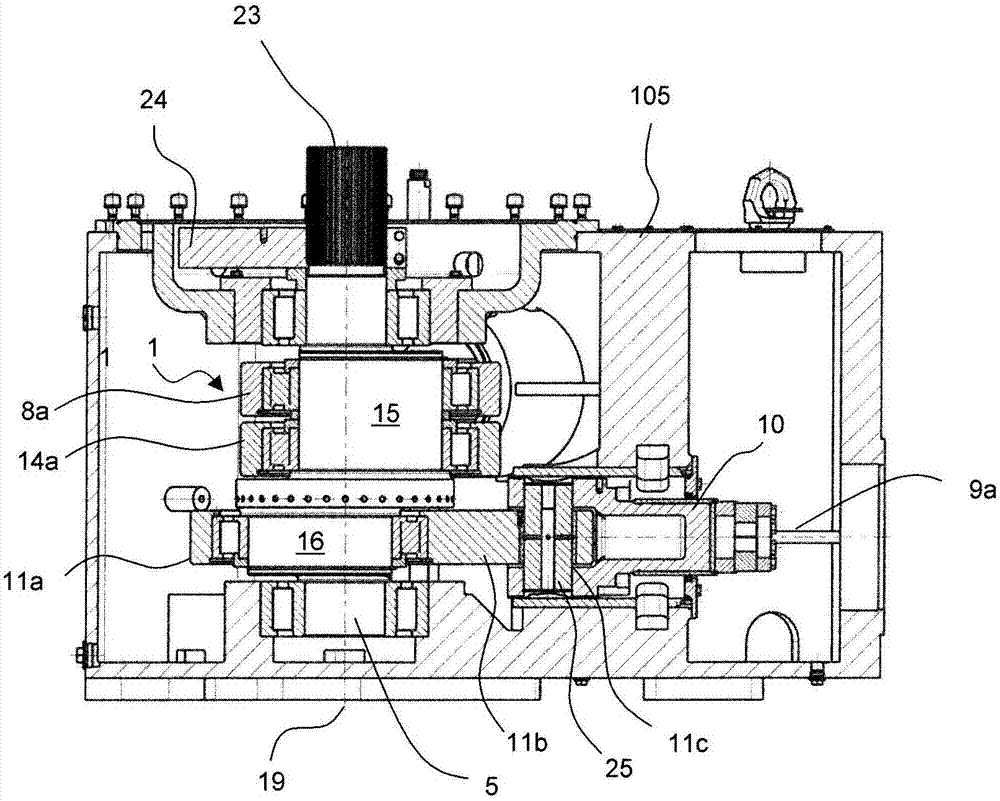

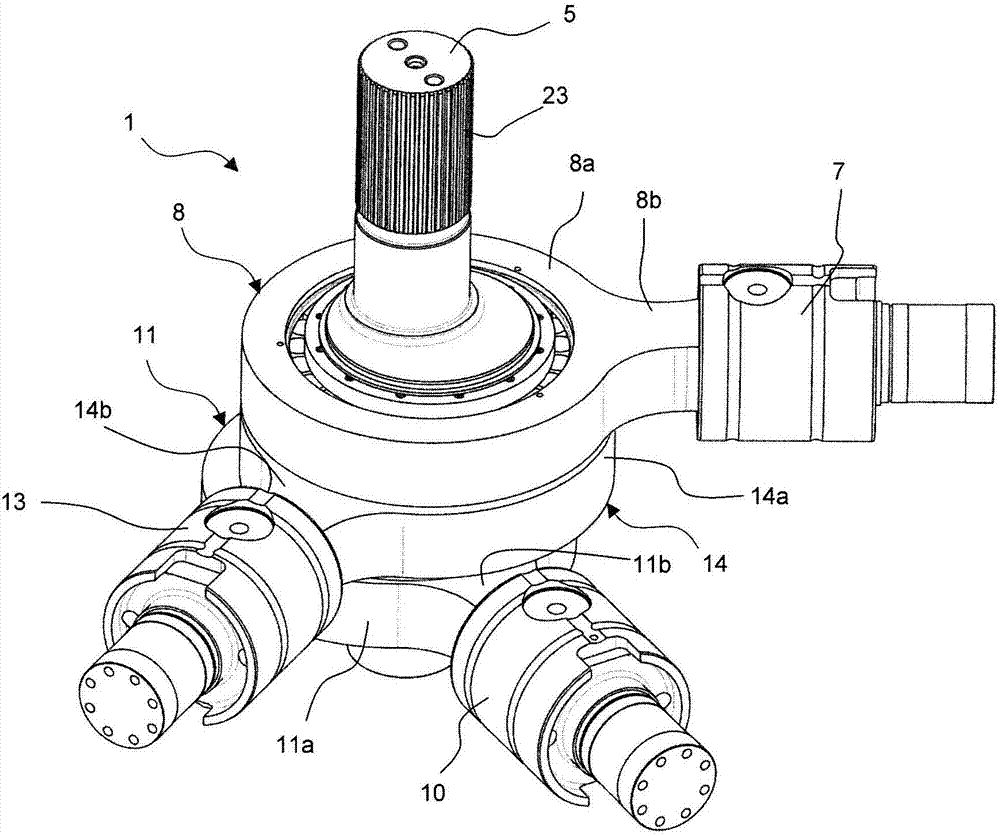

[0036] figure 2 A section through the housing 105 is shown in (the drive unit 101 is not shown). It can be seen how th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com