Insulated gate power semiconductor device and method for manufacturing such a device

A technology of power semiconductors and insulated gates, which is applied in the field of power electronics to achieve the effect of improving device reliability and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

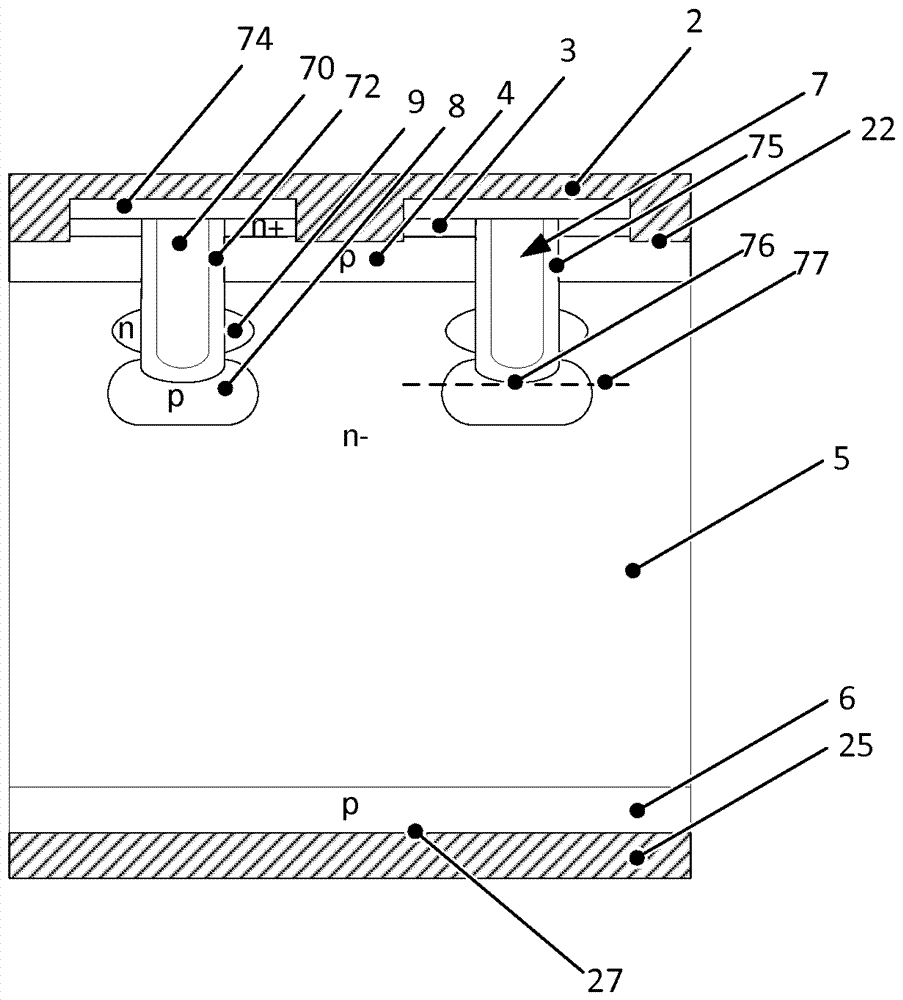

[0052] figure 2 , An inventive insulated gate power semiconductor device in the form of an insulated gate bipolar transistor 1 is shown, which includes an emitter electrode 2 on the emitter side 22 and a collector electrode 25 on the collector side 27, the collector side 27 is arranged opposite to the emitter side 22. The (n-) doped drift layer 5 is arranged between the emitter side 22 and the collector side 27. The p-doped base layer 4 is arranged between the drift layer 5 and the emitter side 22. The base layer 4 contacts the emitter electrode 2. At least one n-doped source layer 3 is arranged on the emitter side 22. The source layer 3 (which is separated from the drift layer 5 by the base layer 4) contacts the emitter electrode 2. The source layer 3 may be arranged such that the source layer 3 is arranged at both sides of each gate electrode 7.

[0053] The device includes: at least one trench gate electrode 7 having a conductive gate layer 70; and a first electrically in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com