Tea oil filter device

A filter device and camellia oil technology, applied in the direction of filtration separation, filter circuit, fat oil/fat refining, etc., can solve problems such as inconvenient cleaning and maintenance, poor quality of camellia oil, affecting enterprise development, etc., to achieve easy cleaning and maintenance, improve Yield, easy to clean the effect of fine filter screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

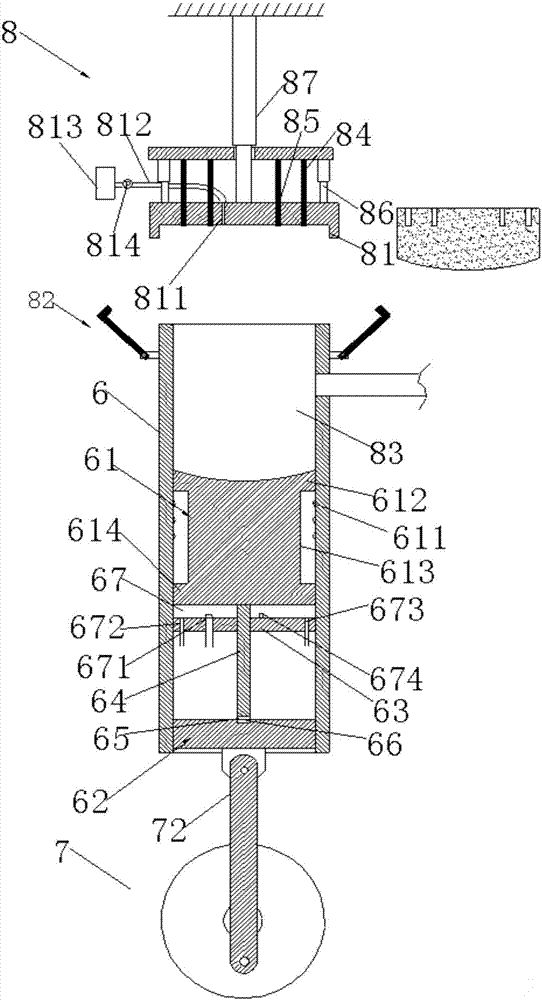

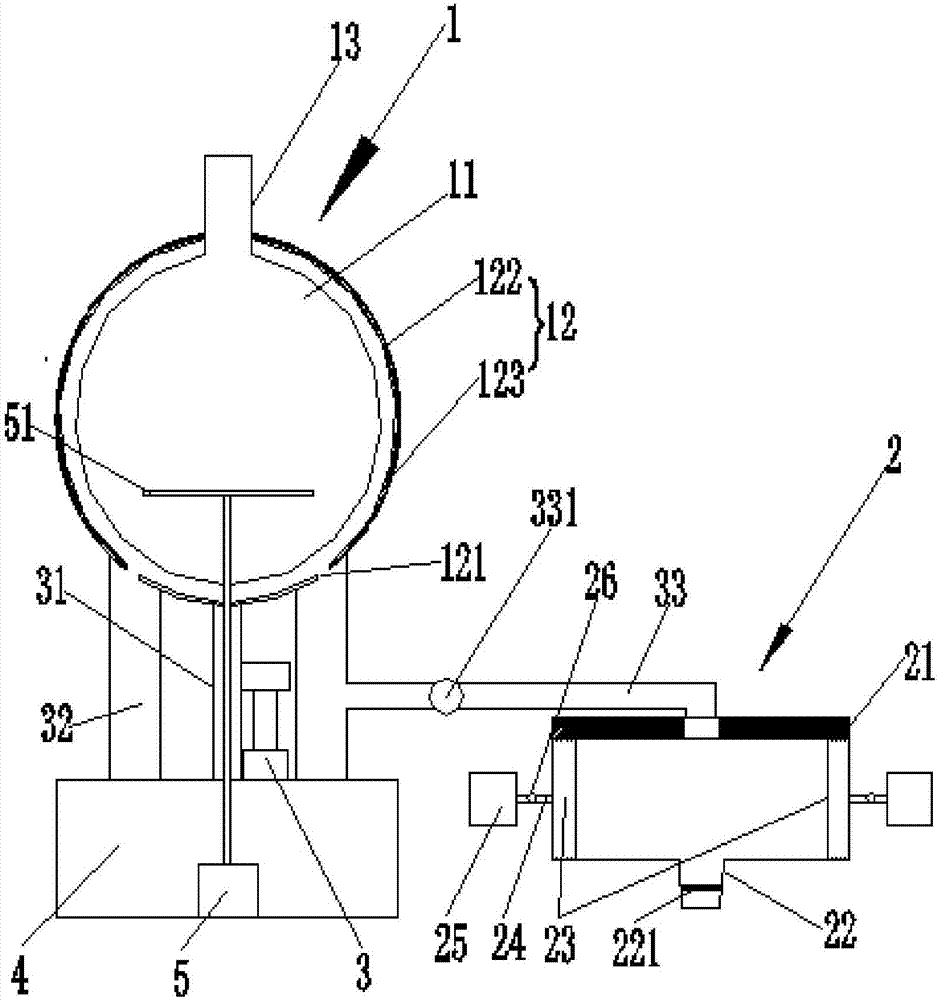

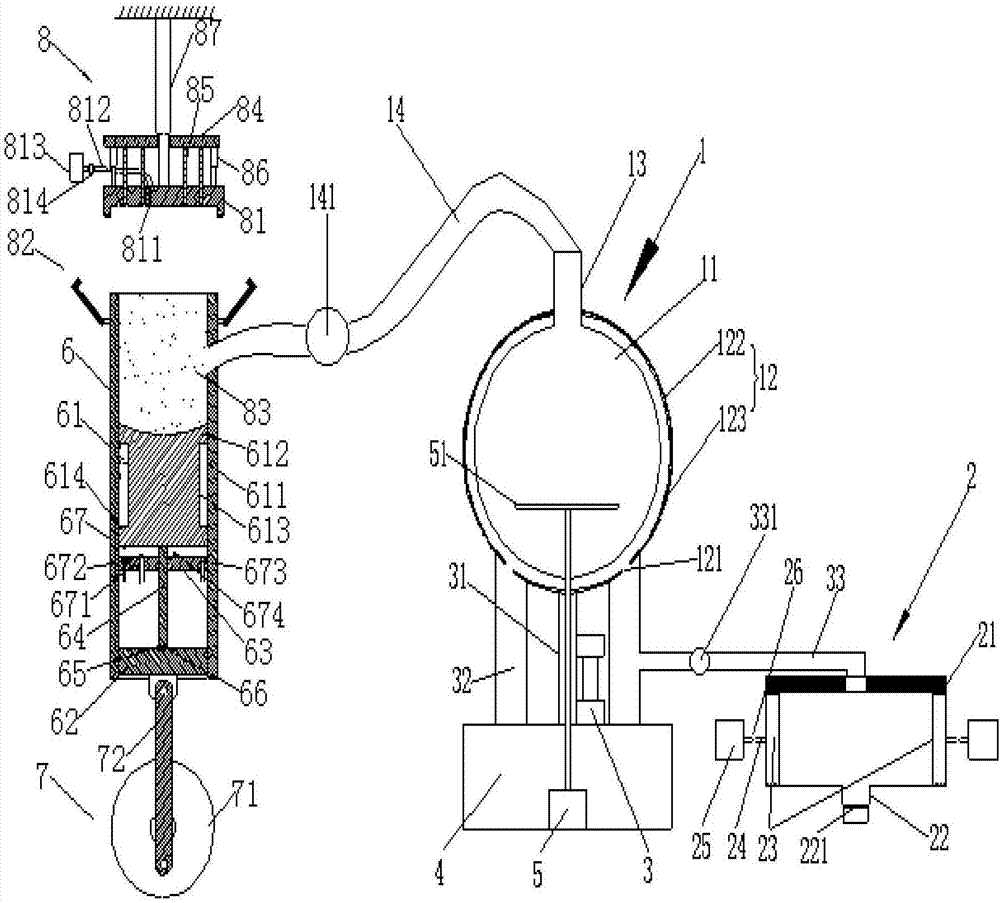

[0033] see Figure 1 to Figure 4 , a camellia oil filtering device, comprising a coarse filter mechanism 1 and a fine filter mechanism 2; the coarse filter mechanism 1 includes a spherical filter screen 11, a spherical housing 12 sleeved outside the filter screen 11, and a liquid inlet Pipe 13; the top of the filter screen 11 is vertically connected with the lower end of the liquid inlet pipe 13, and the lower part of the housing 12 is provided with a plurality of arc-shaped liquid inlets 121; the lower part of the housing 12 is provided with a motor 3, and the motor 3 drives a hollow The rotating shaft 31 rotates, the upper end of the rotating shaft 31 is fixedly connected to the bottom end of the housing 12, and the lower end is rotationally connected to a base 4, and the motor 3 is used to drive the rotating shaft 31 to rotate, thereby dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com