Leather pattern hot stamping machine

A hot stamping machine and pattern technology, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of difficult positioning of molds, troublesome adjustments, inconvenient installation of molds, etc., and achieve good positioning and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

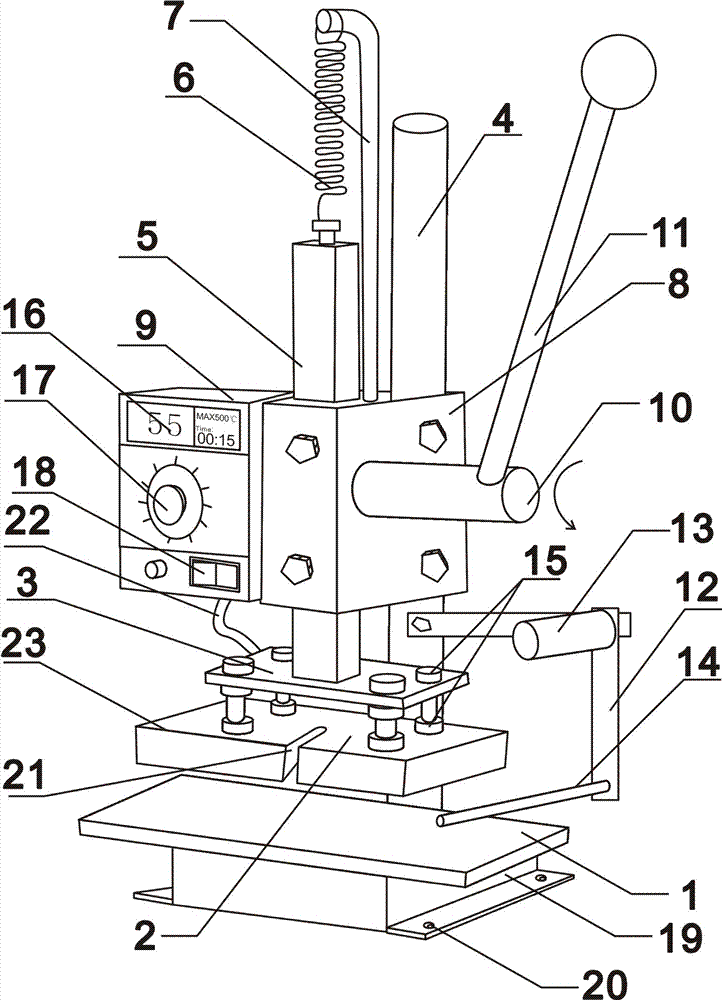

[0022] Such as figure 1 As shown, a leather pattern hot stamping machine includes a workbench 1, a hot pressing plate 2, a mounting plate 3, a support shaft 4, a stamping rod 5, a spring 6, a spring mounting frame 7, a stamping adjustment box 8, a numerical control heating box 9, The handle mounting rod 10, the handle 11, the bronzing support 12, the bronzing drum 13, the balance bar 14, the adjusting screw 15 and the base 19.

[0023] The ironing plate 2 is arranged above the worktable 1, and the ironing plate 2 is fixed to the mounting plate 3 by an adjusting screw 15, the base 19 is fixed to the bottom surface of the worktable 1, and there are lugs on both sides of the base 19, Mounting holes 20 for the base lugs are provided on the lugs. Fix the entire hot stamping machine on the work table through the mounting holes of the lugs.

[0024] The punching adjustment box 8 is fixed on the support shaft 4 and can slide up and down along the support shaft 4. The bottom end of the pu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap