Device for providing paper tubes for film winder

A paper tube and film wrapping technology, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, can solve the problems of troublesome operation, low production efficiency, and large investment in equipment, and achieve easy operation, improved production efficiency, The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

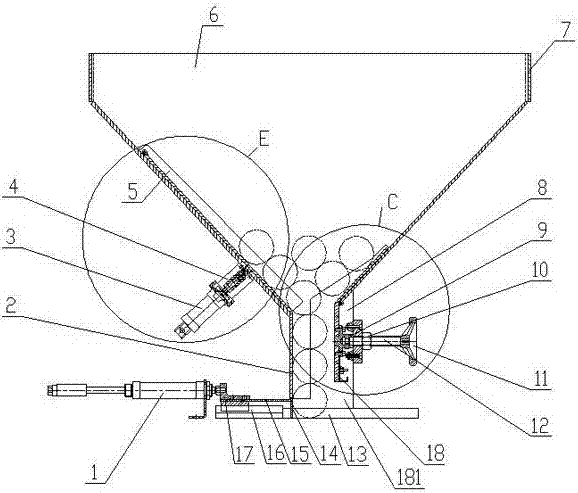

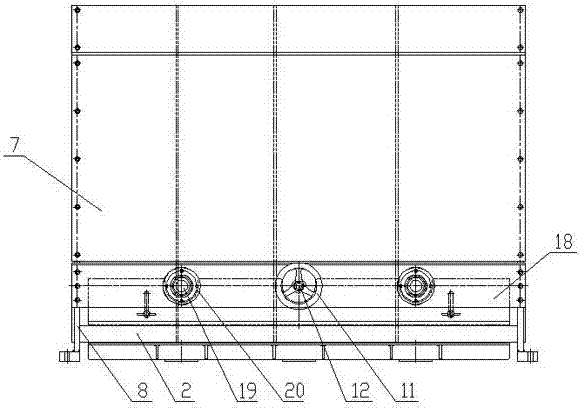

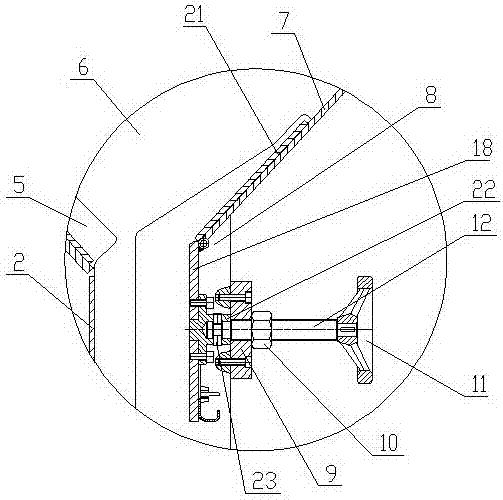

[0019] Such as figure 1 , figure 2 with image 3 As shown, the device for providing paper tubes for the film winding machine according to the present invention includes a hopper 7 and a platen 13 , and the hopper 7 is located above the platen 13 . Both the feed inlet and the discharge port of the hopper 7 are rectangular, and a width adjustment mechanism for adjusting the width of the discharge port is arranged below the discharge port.

[0020] The width adjustment mechanism includes a long lower extension plate 2 extending downward along one long side of the discharge opening and two short lower extension plates 8 extending downward along the two short sides of the discharge opening. A first bracket 9 is arranged under the long side of the extension plate 2 . The first bracket 9 is a long strip, and its two ends are respectively fixed on the vertical edge of the two short lower extension plates 8 away from the long lower extension plate 2 by means of screws.

[0021] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com