Amphibious sewage pump

A technology for amphibious and sewage pumps, applied to pumps, pump components, components of pumping devices for elastic fluids, etc., can solve the problem of motor winding insulation breakdown and short-circuit burning, failure to pump special areas, and limited use range Limitation and other problems, to achieve the effect of convenient operation and maintenance, flexible use method, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

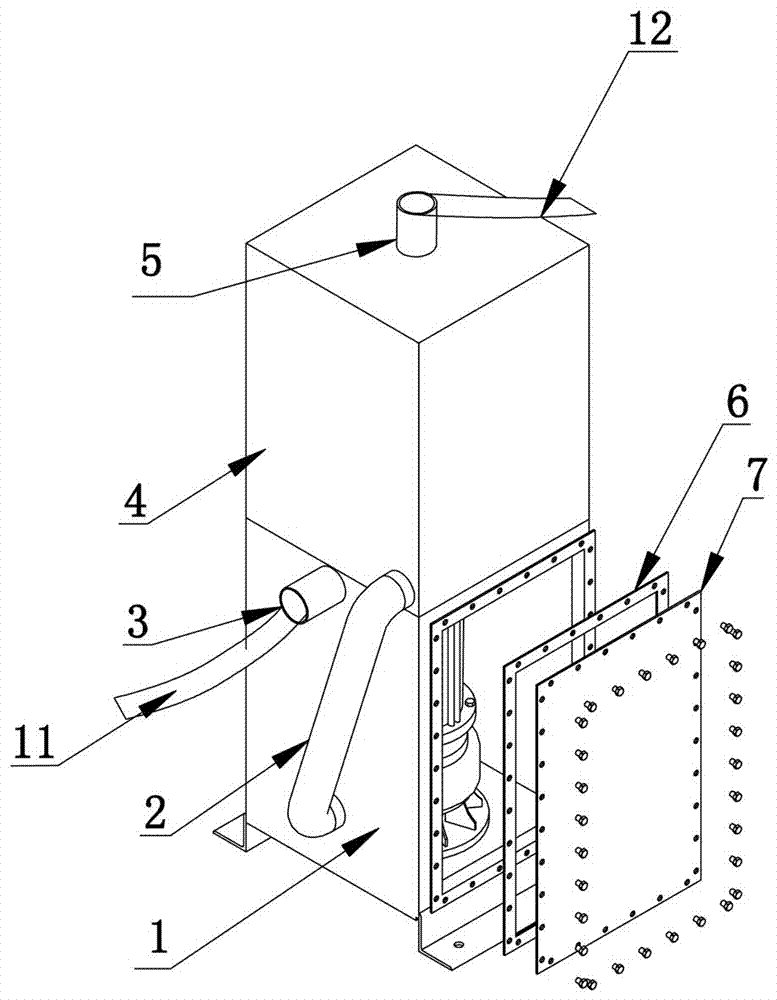

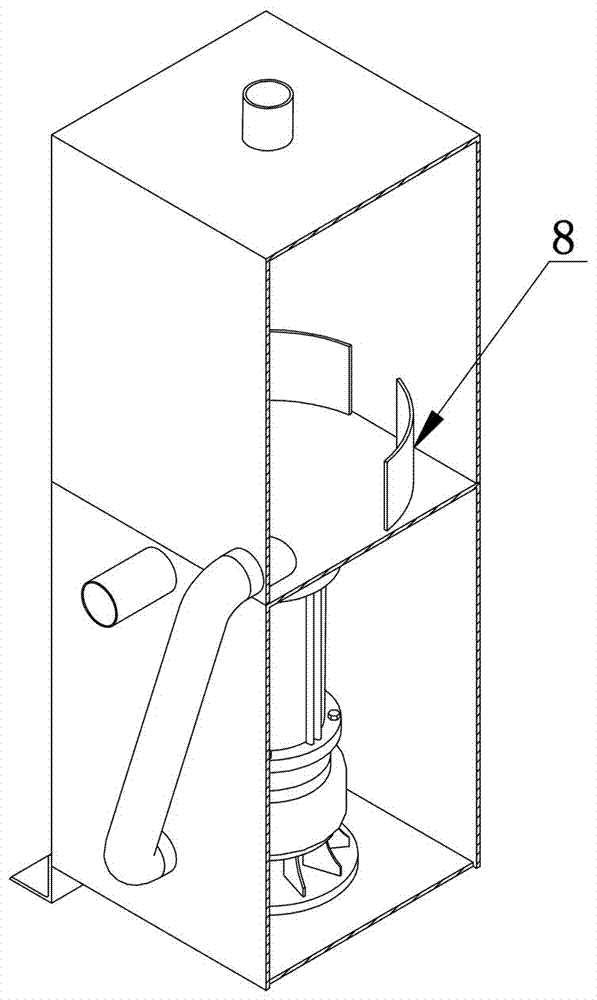

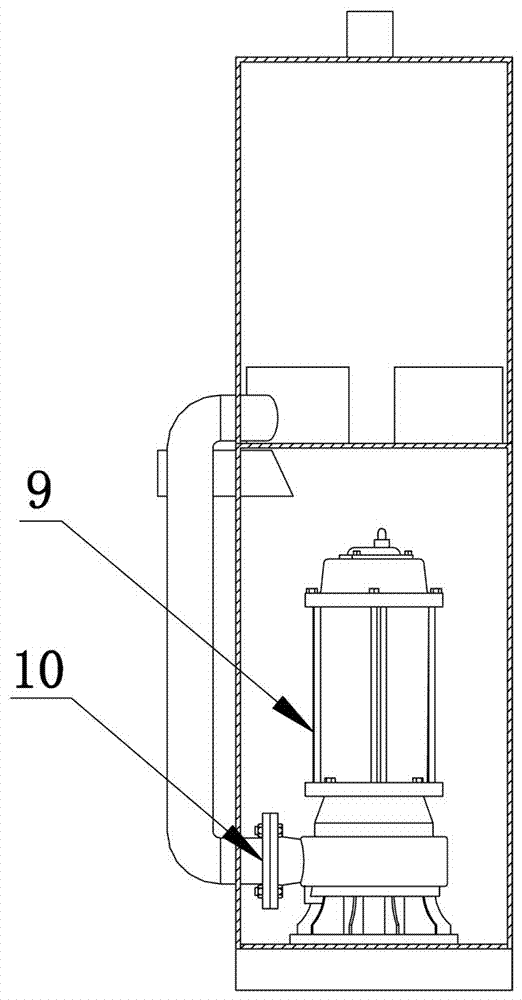

[0021] Such as figure 1 , 2 As shown in and 3, an amphibious sewage pump of the present invention includes a sewage submersible pump 9, and an outlet flange 10 arranged at the outlet of the sewage submersible pump 9 is characterized in that it also includes an upper box body 4 and a lower box body 1, the middle pipe 2 connecting the upper box 4 and the lower box 1, the water suction pipe 3 located on the top side wall of the lower box 1 and communicating with the lower box 1, and The guide pipe I11 connected to the water suction pipe 3, the drain pipe 5 arranged on the top of the upper box body 4, the guide pipe II12 connected to the drain pipe 5, the guide pipe arranged in the upper box body 4 Flow plate group, the sewage submersible pump 9 is sealed in the lower box 1 by the sealing cover 7 and the sealing gasket 6, the sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com