Programmable constant temperature constant humidity testing box use method and programmable constant temperature constant humidity testing box control method

A constant temperature and humidity test and control method technology, applied in the field of test equipment, can solve problems such as unstable water supply, experimental errors, unfavorable monitoring of real-time temperature and humidity, etc., achieve good temperature stability and durability, and improve safety and reliability Sex, matching and assembly matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

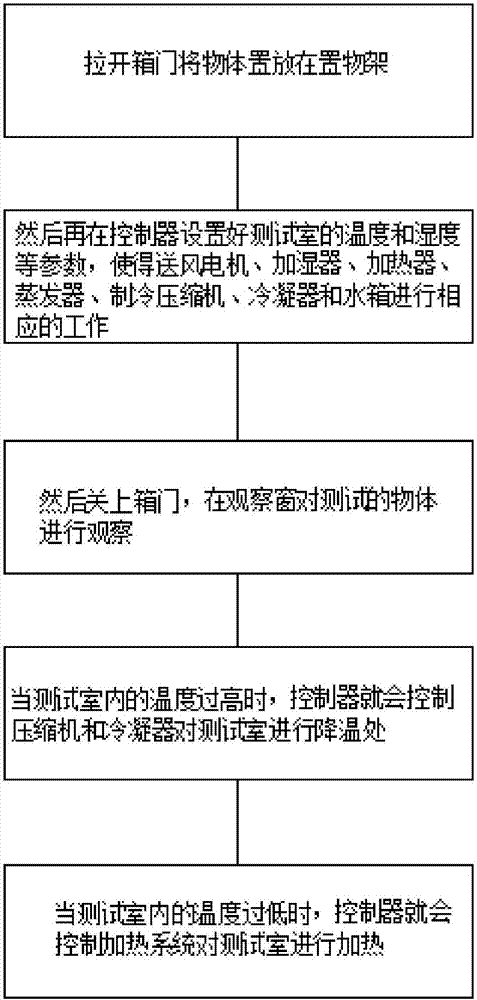

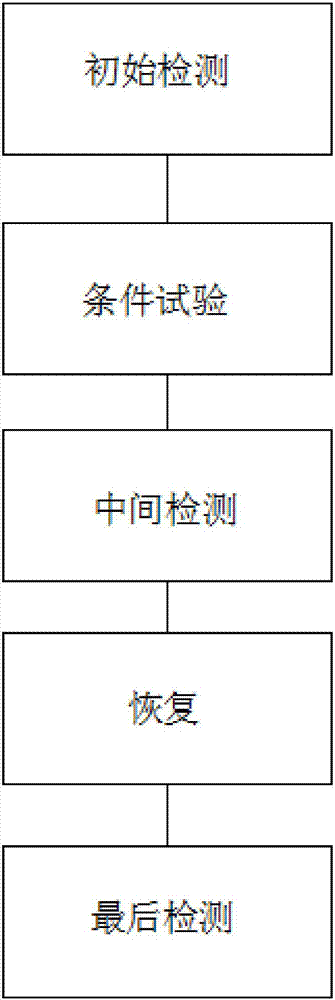

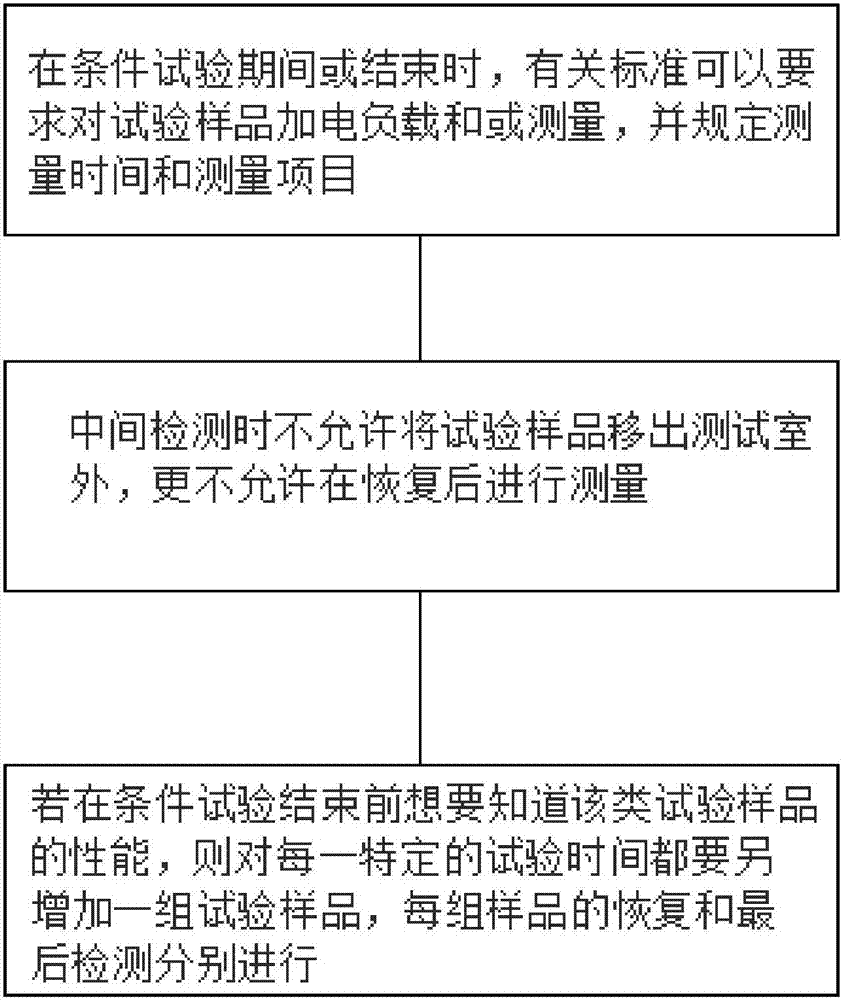

[0023] Such as figure 1 and combine figure 2 and image 3 As shown, the method of using the programmable constant temperature and humidity test box is as follows: (1) open the door of the box and place the object on the shelf; (2) and then set the temperature and humidity parameters of the test room on the controller , so that the blower motor, humidifier, heater, evaporator, refrigeration compressor, condenser and water tank work accordingly; (3) then close the door and observe the test object in the observation window; (4) when When the temperature in the test chamber is too high, the controller will control the compressor and condenser to cool down the test chamber; (5) When the temperature in the test chamber is too low, the controller will c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com