Smart energy high-tension-resistance cable and production technology therefor

A smart energy and production technology technology, applied in communication cables, submarine cables, insulated cables, etc., can solve the problems of increased cable hardness, and achieve the effects of improving tensile performance, uniform gaps, and high softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

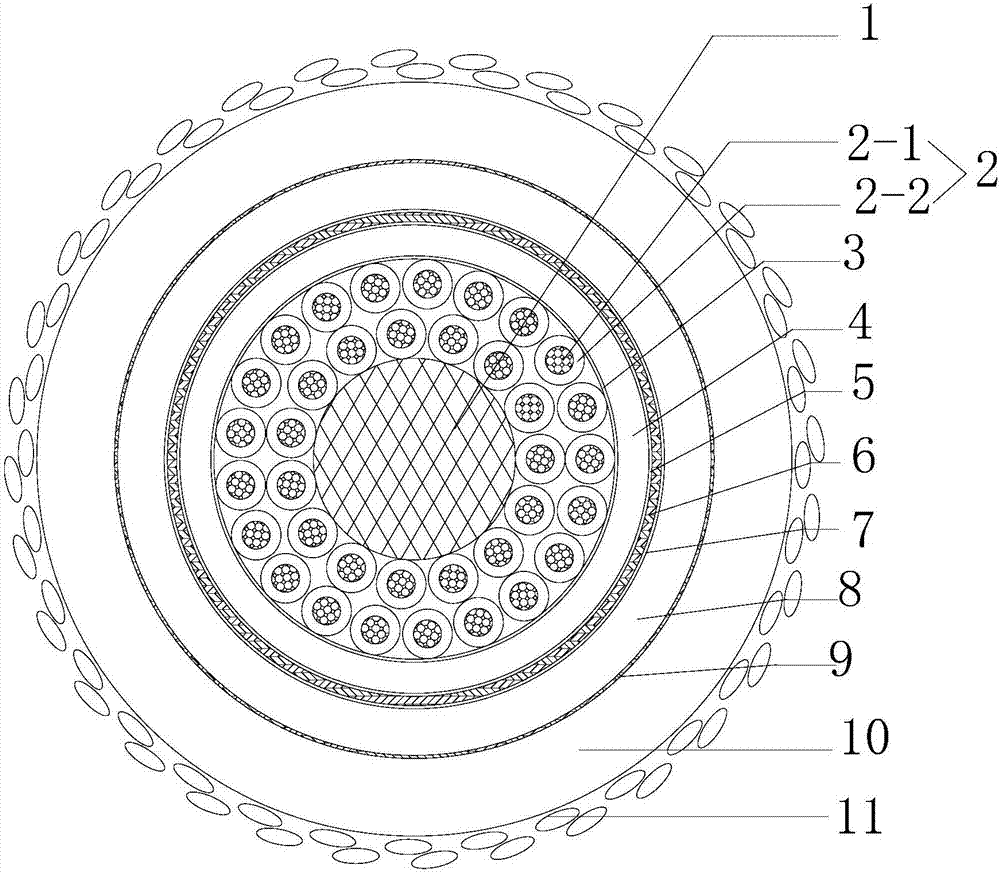

[0039] See figure 1 , a smart energy high-strength cable in this embodiment, from the inside to the outside is the strengthening core 1, the cable core, the first polyester tape 3, the rubber cushion layer 4, the aluminum-plastic composite tape 5, and the copper wire shielding layer 6 , the second polyester tape 7, the inner sheath 8, the first braided layer 9, the outer sheath 10 and the second braided layer 11; the cable core includes 36 insulated wire cores 2 arranged in a manner of arranging one outside the reinforcing core 1 A layer of 15 insulated wire cores 2 and a layer of 21 insulated wire cores 2; each insulated wire core 2 includes a conductor 2-1 and a fluoroplastic insulation 2-2 from the inside to the outside; the reinforcing core 1 is braided with bulletproof wire, and the reinforcing core The outer diameter of 1 is determined according to the formula: D=(4.154+k)×d, k is the compression coefficient, when d is 1.0-2.0mm, k is 0.05, when d is 2.0-4.0mm, k is 0.07...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap