Letter box device with high efficiency

A high-efficiency, letterbox technology, applied to other household appliances, household components, household appliances, etc., can solve the problems of complicated operation, time-consuming and labor-intensive, low production efficiency, etc., and achieve the effect of convenient operation, reduced equipment investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

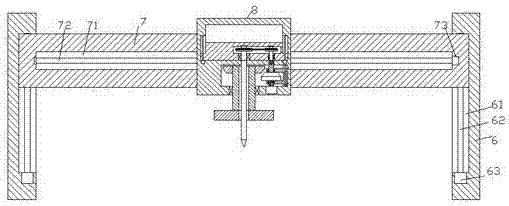

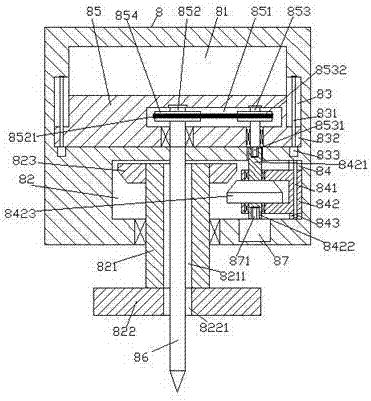

[0025] Such as Figure 1-Figure 6As shown, a high-efficiency letter box device of the present invention includes a body composed of a support rod 6 and a top beam 7, and a manipulation assembly 8 is arranged in the body, and a first hollow cavity 81 is provided in the manipulation assembly 8. , the inner walls of the left and right sides of the first hollow cavity 81 are mutually symmetrically provided with a first sliding groove 83, and a first screw-shaped rod 831 is arranged in the first sliding groove 83, and a sliding rod 831 is arranged in the first hollow cavity 81. A first sliding block 85 is connected by shift fit, a second hollow cavity 82 is arranged in the manipulation assembly 8 below the first hollow cavity 81, and a guide groove 84 is provided on the inner wall of the right side of the second hollow cavity 82. , the guide groove 84 is provided with a guide rod 841, and the guide rod 841 is slidably connected with a guide frame 842 that penetrates into the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com