Turbo fan type sand washing sand water separation device

A sand-water separation and sand-washing technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of low efficiency, obvious sand discharge odor, poor separation effect, etc. The effect of reducing the amount of energy and eliminating the impact of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

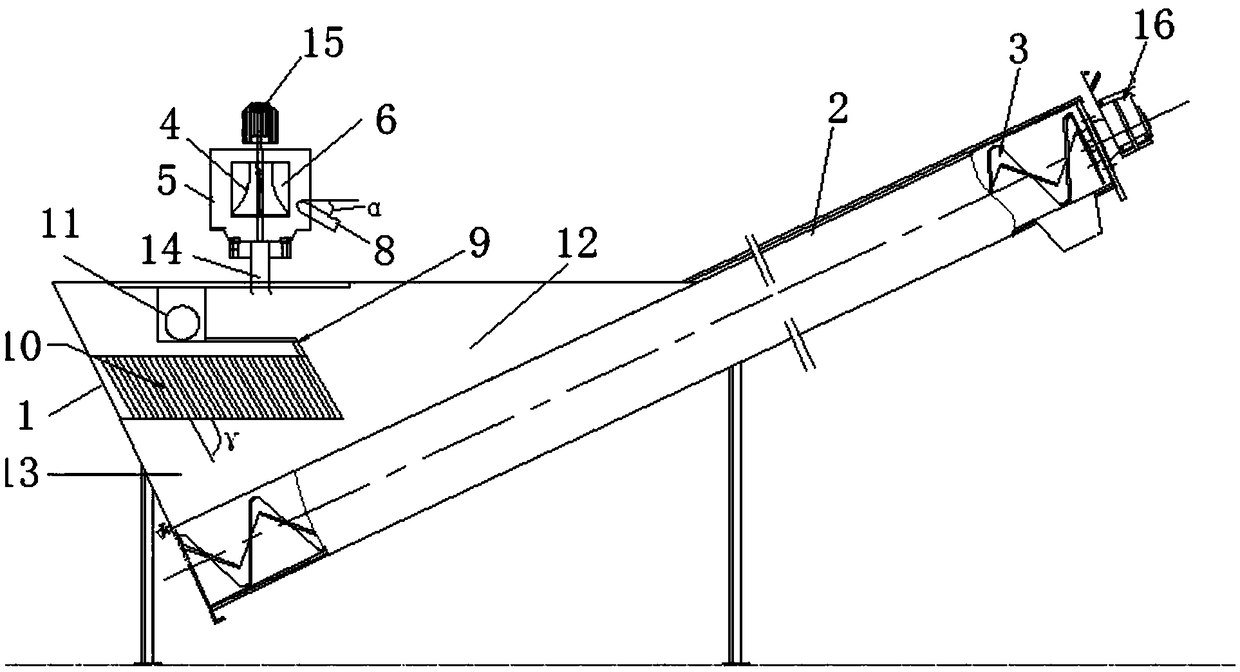

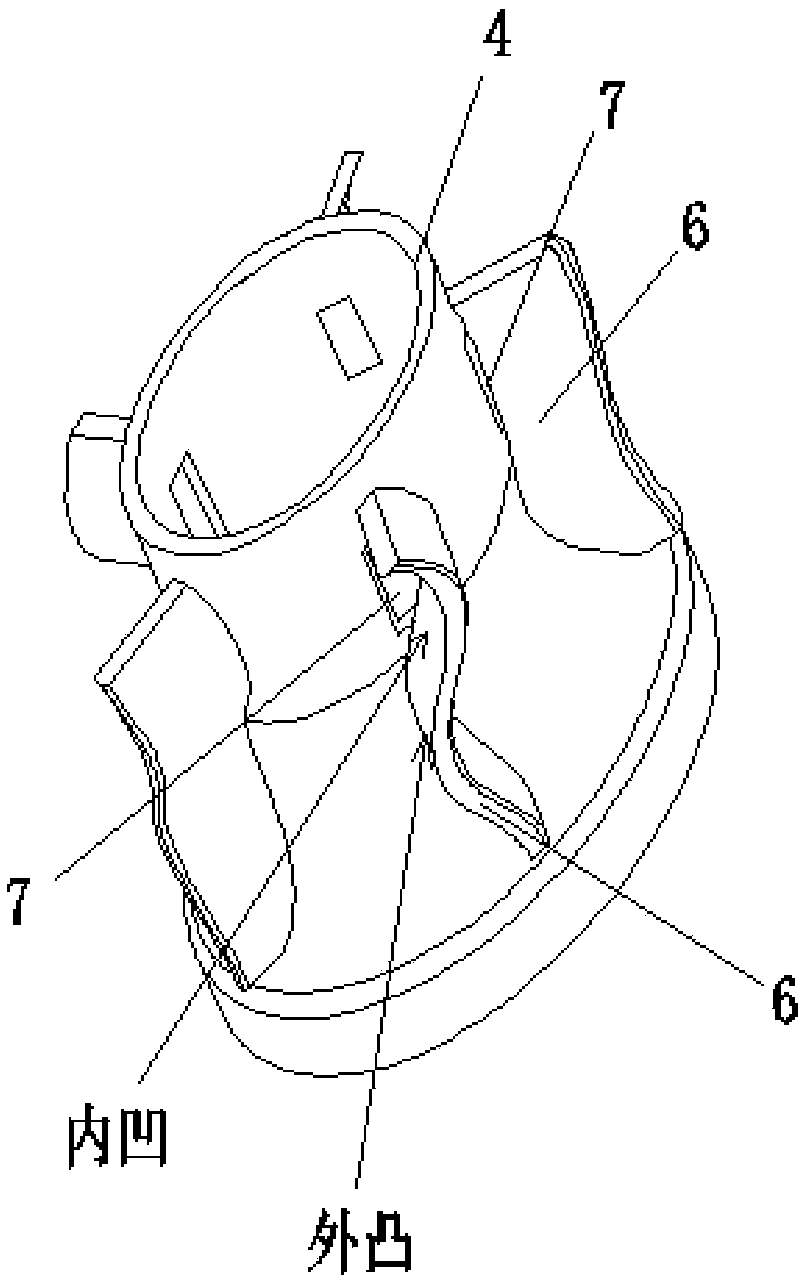

[0017] combine figure 1 — Figure 4 Shown, a turbofan type sand washing sand water separation device is mainly composed of two parts: a spiral sand water separator and a turbofan type sand washing drum.

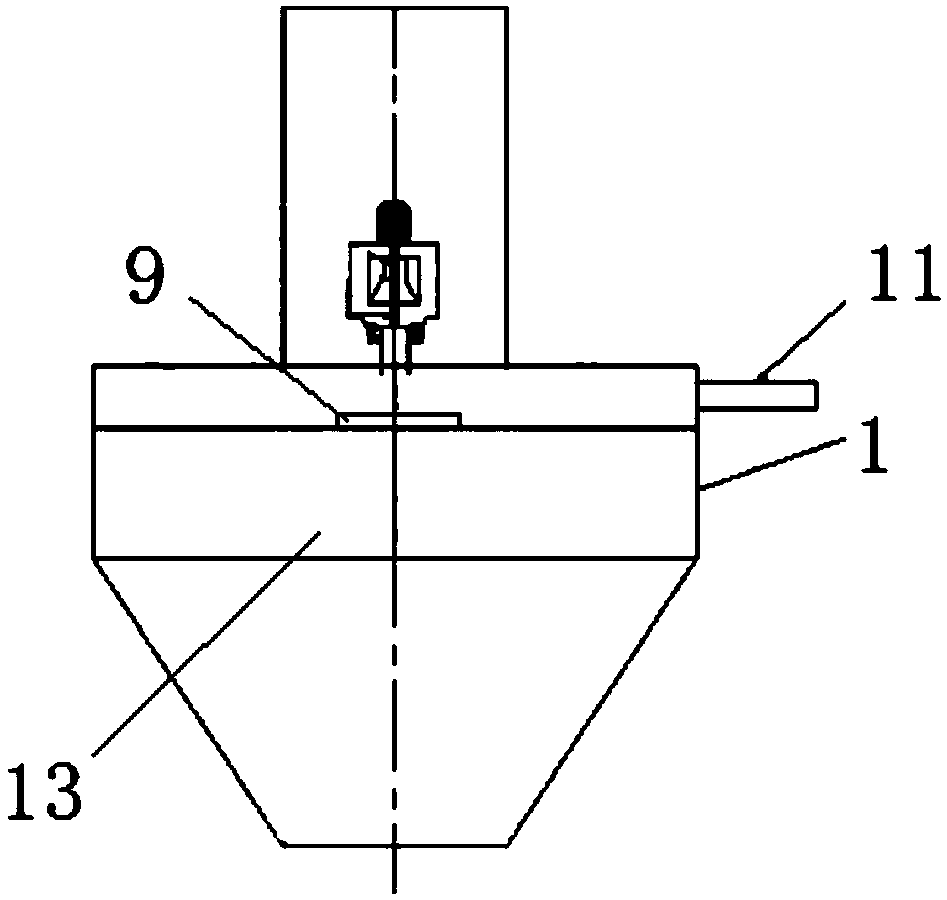

[0018] The spiral sand-water separator is mainly composed of a water collection tank 1, a U-shaped conveying tank 2, a screw conveyor 3, a flow guide 9, a settling swash plate 10, and a first motor 16.

[0019] The U-shaped conveying trough 2 is set with a low left and right high slope, the water collection tank 1 is set directly above the left end of the U-shaped conveying trough 2, the screw conveyor 3 is installed in the U-shaped conveying trough 2, and the rotation of the screw conveyor 3 is controlled by a belt reducer The drive of the first motor 16 belongs to conventional technical means. The screw conveyor 3 is preferably shaftless screw conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com