Waste material discharging device and stamping die system

A technology of discharge device and stamping die, which is applied in the direction of pushing out equipment, etc., can solve the problems of insufficient waste discharge, inability to discharge waste, limited movement frequency, etc., to achieve rapid and effective discharge, increase movement frequency, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

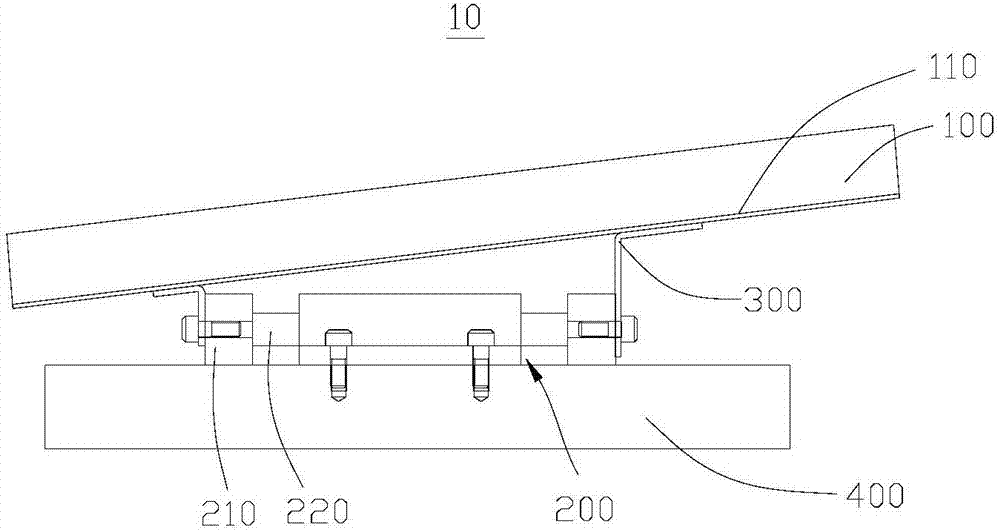

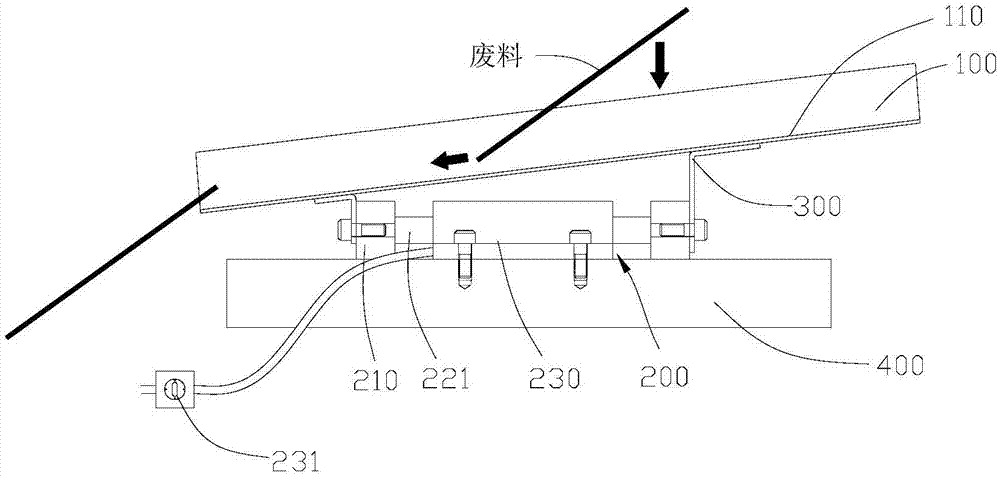

[0034] see figure 1 , the present embodiment provides a waste material discharge device 10, which is applied to the discharge of waste materials from stamping dies (not shown in the figure), which can quickly and effectively discharge the waste materials falling on the waste material discharge device 10, avoiding the accumulation and blockage of waste materials technical problems.

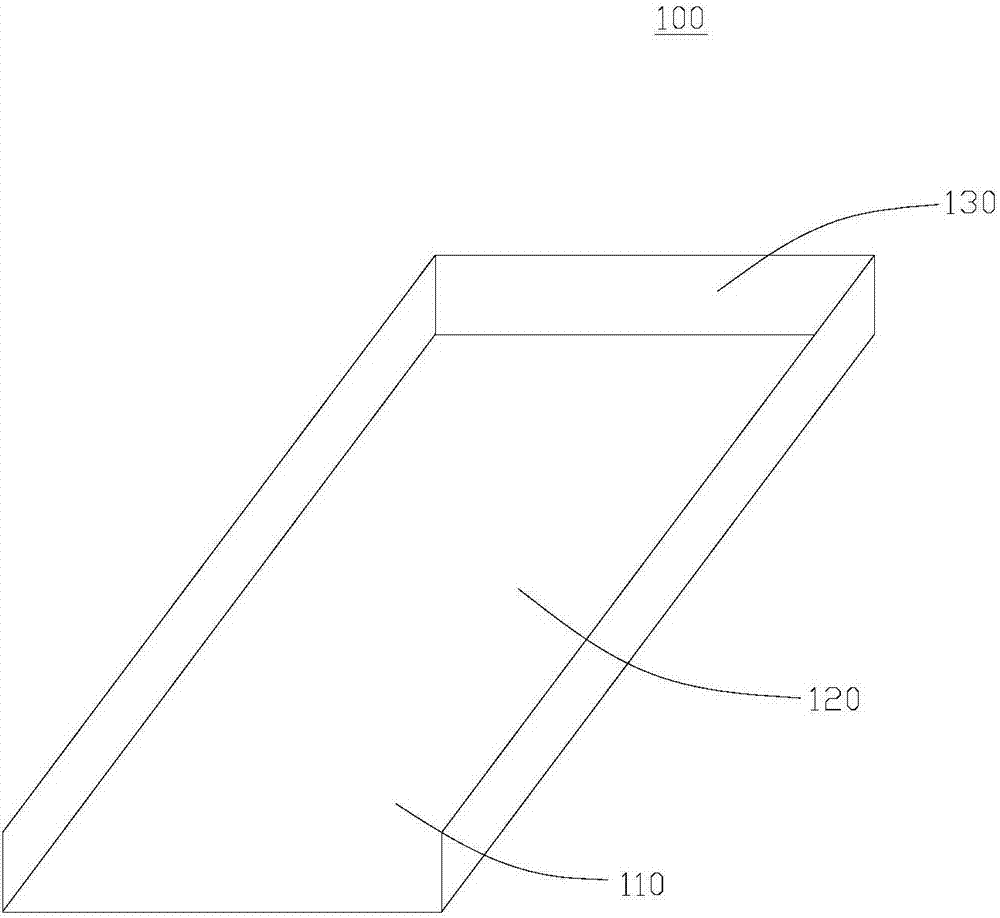

[0035] The waste material discharge device 10 includes a receiving structure 100 and a power unit 200, wherein the power unit 200 includes a movable part 210 and a guide structure 220, the movable part 210 is connected with the guide structure 220, and the movable part 210 can do linear reciprocating motion along the guide structure 220, accepting The structure 100 is fixedly connected with the movable part 210 , so that the receiving structure 100 can follow the movable part 210 to make linear reciprocating motion along the guide structure 220 . In addition, the receiving structure 100 has a rece...

no. 2 example

[0050] This embodiment provides a stamping die system (not shown), which adopts the waste discharge device 10 provided in the first embodiment, which can quickly and effectively discharge the waste falling on the waste discharge device 10, Avoid technical problems with clogging of waste accumulation.

[0051] Wherein, the stamping die system includes a stamping die (not shown) and a waste discharge device 10 . The stamping die includes an upper die (not shown) and a lower die (not shown). The upper die can reciprocate relative to the lower die. The upper die can selectively cooperate with the lower die to process products and generate waste, or the upper die is far away from the lower die. die in preparation for the next machining. And the stamping die can discharge the waste material along the first direction. In this embodiment, the movement of the waste discharge device 10 and the movement of the upper die are independent of each other, that is, the movement of the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com