Abrasive grinding wheel outer circle processing device and processing method

The technology of a processing device and a processing method, which is applied to the field of the outer cylindrical processing device for grinding the outer circumference, can solve the problems such as the inability to realize automatic loading and unloading, and achieve the effects of improving the working efficiency, improving the degree of automation, and moving quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings.

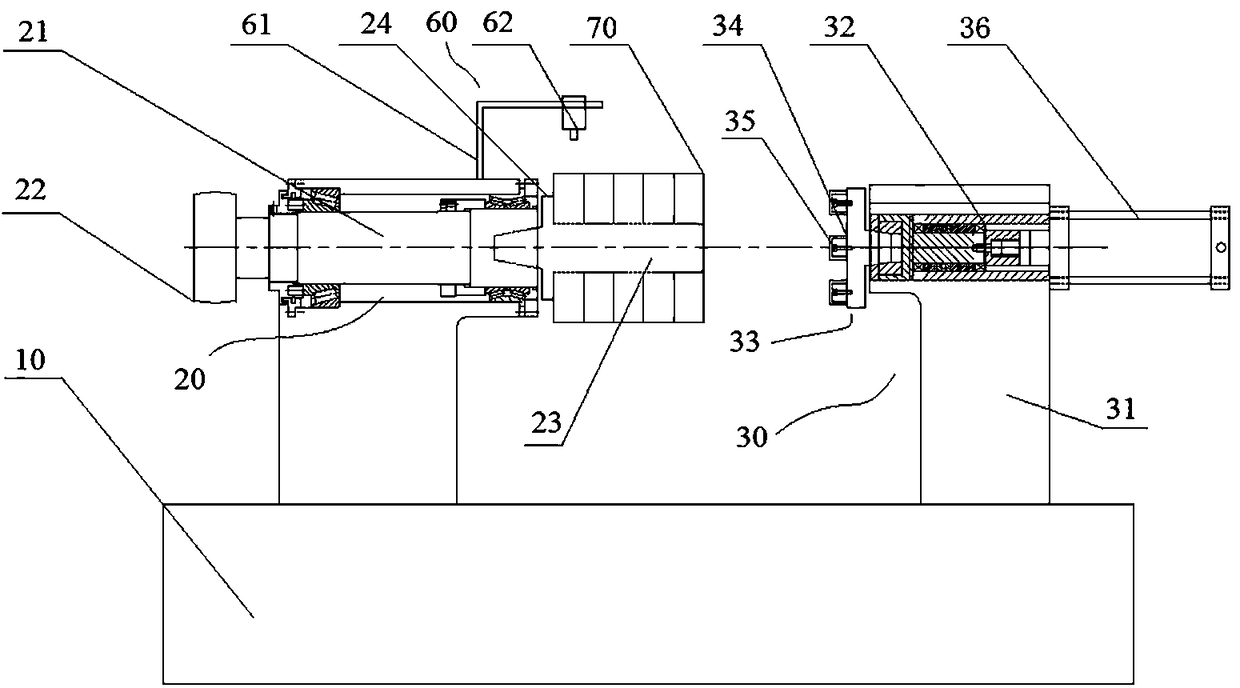

[0023] An example of the external processing device of the abrasive grinding wheel in the present invention Figure 1~Figure 2 Shown is a general abrasive grinding wheel external machining device, including a base 10 on which is provided with a spindle device 20, a tightening device 30 arranged collinearly with the spindle device 20, and a feed device 40 with a diamond grinding wheel 41 installed. And an automatic loading and unloading device 50 for realizing the loading and unloading of the grinding wheel workpiece 70.

[0024] The base 10 is the base body of the entire ordinary abrasive grinding wheel external machining device. It is provided with a motor for driving the grinding wheel clamping shaft 23 of the spindle device 20 to rotate. The left end of the spindle 21 of the spindle device 20 is provided with a pulley 22, which is connected to the The motor is connected to drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com