Vehicle door, manufacturing method of vehicle door, reinforcing structural body as well as vehicle using vehicle door

A technology for strengthening structures and doors, applied in the field of vehicles, can solve the problems of high fuel consumption, high production costs, and heavy metal doors, and achieve the effects of reducing fuel consumption, improving firmness, and reducing overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

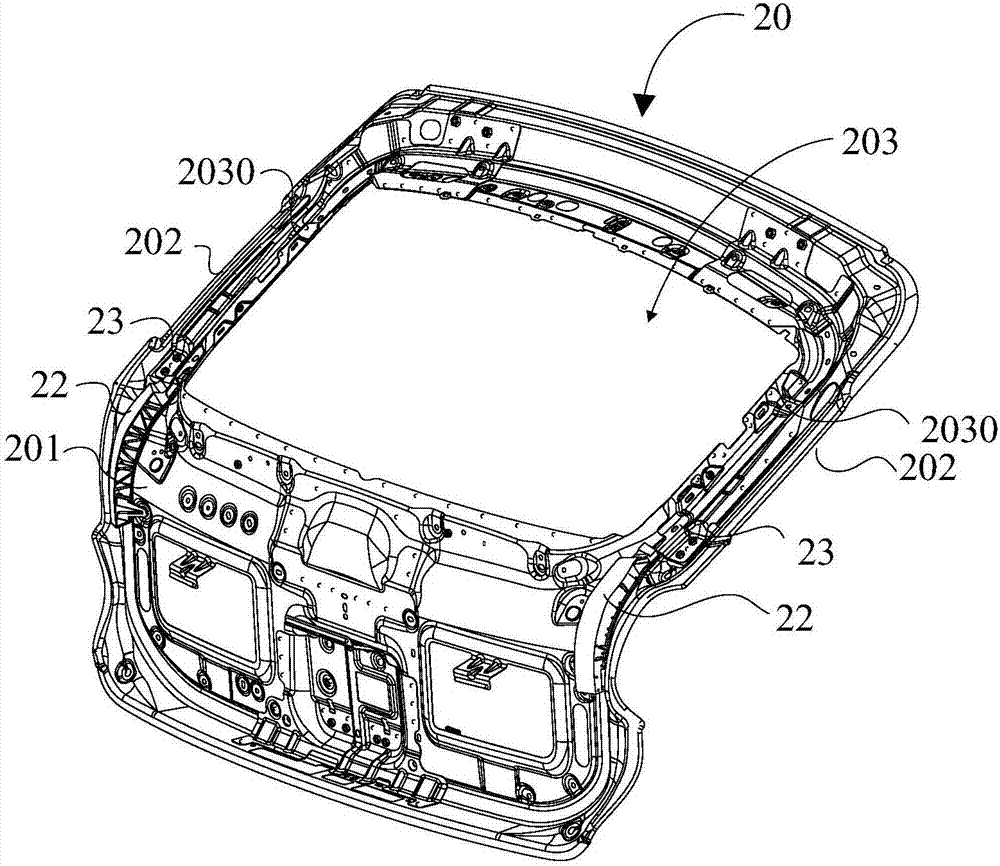

[0102] Various embodiments of the invention will be described with reference to the accompanying drawings. In the description and drawings, elements with similar structures or functions will be denoted by the same symbol. It can be understood that the drawings are only used for reference and description, and are not intended to limit the present invention. The dimensions shown in the drawings are only for the convenience of clear description, and do not limit the proportional relationship or give an exhaustive description of the present invention, nor limit the scope of the present invention.

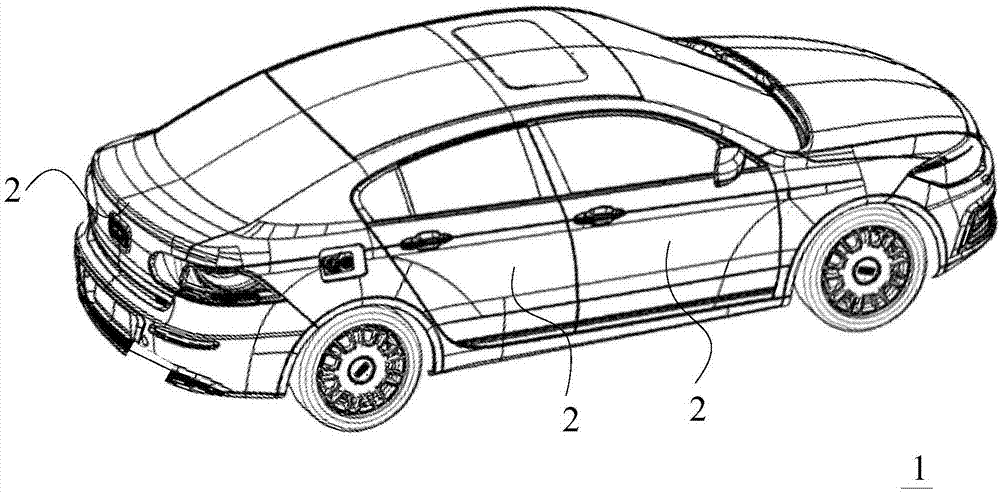

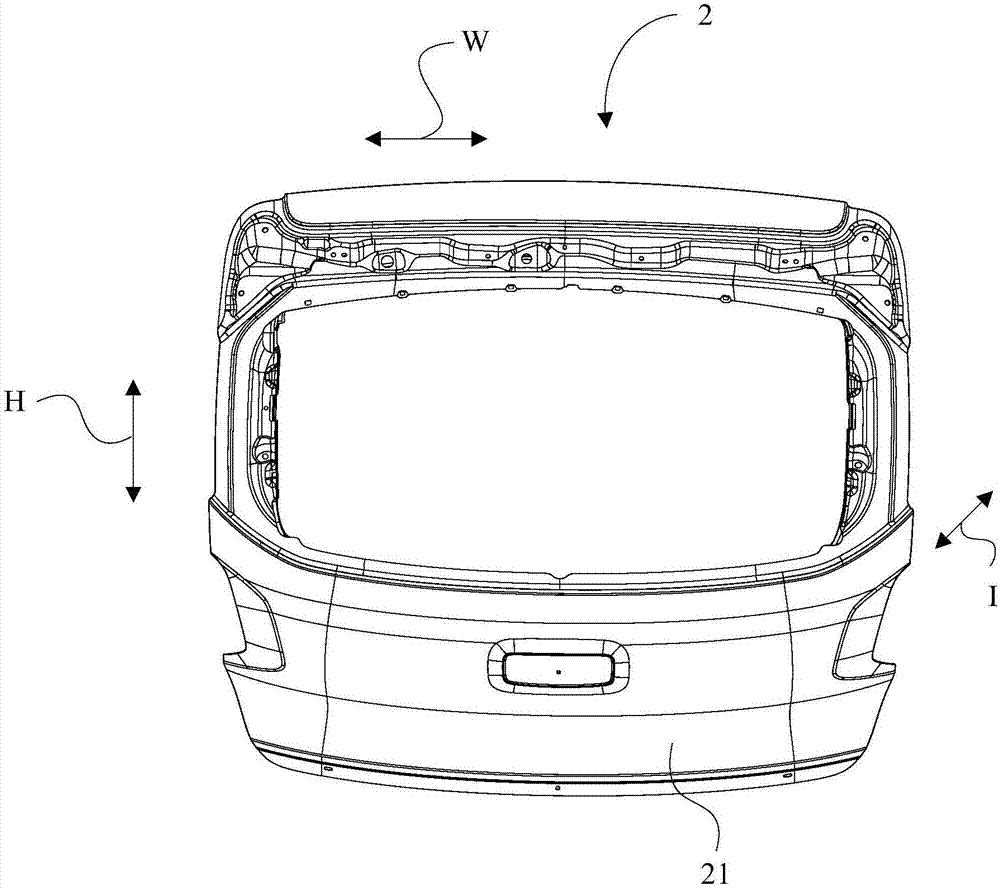

[0103] figure 1 A schematic structure of a vehicle 1 is shown according to an exemplary embodiment of the present invention. A vehicle 1 generally includes a body and a door 2, and the door 2 is used to define a compartment together with the body. The car door of this embodiment can be used for any vehicle, and the car door of this embodiment is a tailgate. Certainly, the car door am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com