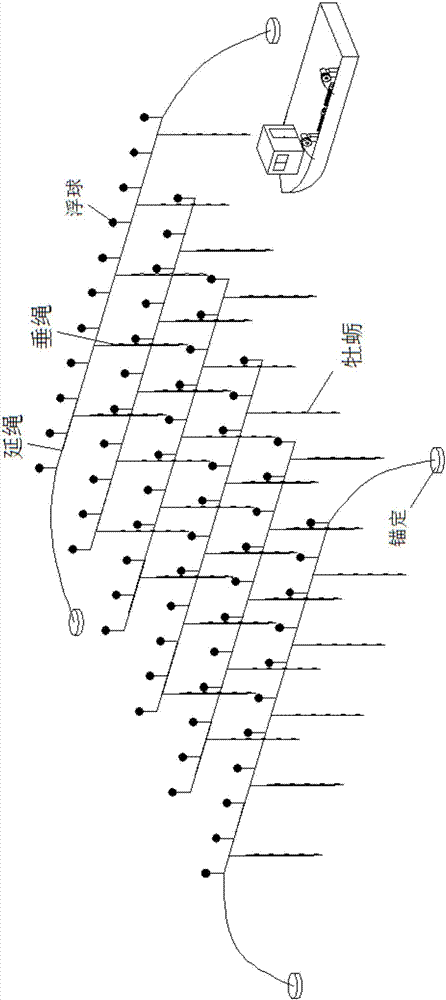

Trotline type cultured oyster mechanized harvest ship and harvest method thereof

A harvesting method and longline technology are applied to the longline cultured oyster mechanized harvester and the harvesting field thereof, which can solve the problems of high labor consumption, low degree of mechanization, low efficiency, etc. The effect of increased automation and simplified processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

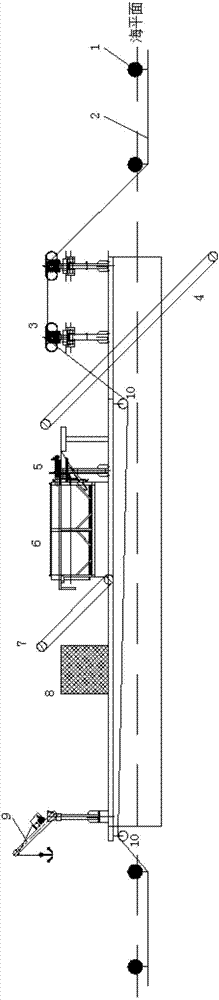

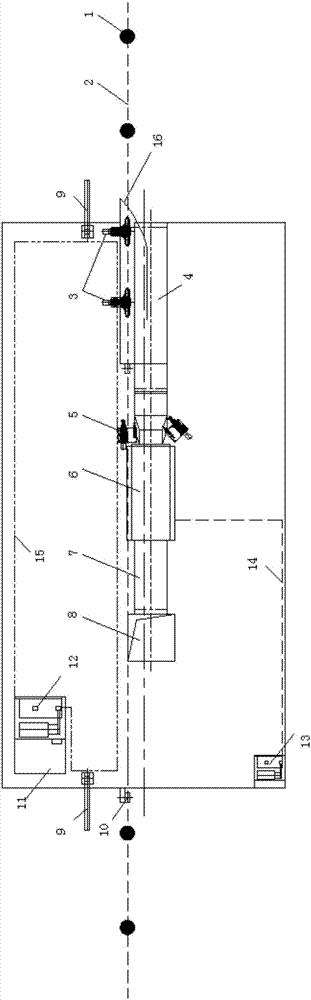

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] see Figure 2-6 , a long-line type cultured oyster mechanized harvesting ship, the middle part of the hull has a long groove for the longline to pass through, and a catch device is arranged on both sides of the long groove; the catch device includes a crane 9, a power block 3, a rocker Partition conveyor 4, guide wheel 10; described power block 3 has the traction wheel 3b that accepts long rope, and the outer side of described traction wheel 3b is fixedly provided with guide rope frame 3a, and described rope guide frame 3a is inclined from bottom to top to Outside, it is used to leave the vertical rope outward to avoid the vertical rope from being involved in the traction wheel 3b; the power tackle has at least two; the crane 9 is used to hang the longline on the traction wheel after hoisting 3b; the rocker-arm partition conveyor 4 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com